Question: subject : process control Transesterification route is the most common method of processing vegetable oil (oil/triglycerides) with methanol (fed in excess) leads to fatty acid

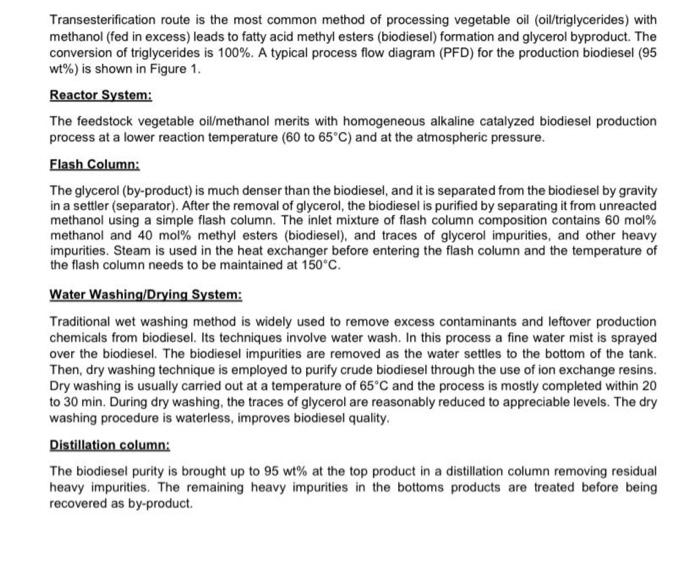

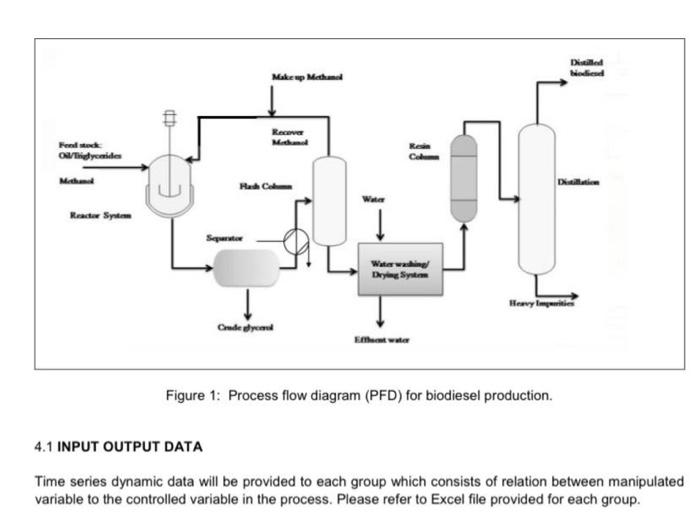

Transesterification route is the most common method of processing vegetable oil (oil/triglycerides) with methanol (fed in excess) leads to fatty acid methyl esters (biodiesel) formation and glycerol byproduct. The conversion of triglycerides is 100%. A typical process flow diagram (PFD) for the production biodiesel (95 wt\%) is shown in Figure 1. Reactor System: The feedstock vegetable oil/methanol merits with homogeneous alkaline catalyzed biodiesel production process at a lower reaction temperature (60 to 65C) and at the atmospheric pressure. Flash Column: The glycerol (by-product) is much denser than the biodiesel, and it is separated from the biodiesel by gravity in a settler (separator). After the removal of glycerol, the biodiesel is purified by separating it from unreacted methanol using a simple flash column. The inlet mixture of flash column composition contains 60mol% methanol and 40mol% methyl esters (biodiesel), and traces of glycerol impurities, and other heavy impurities. Steam is used in the heat exchanger before entering the flash column and the temperature of the flash column needs to be maintained at 150C. Water Washing/Drying System: Traditional wet washing method is widely used to remove excess contaminants and leftover production chemicals from biodiesel. Its techniques involve water wash. In this process a fine water mist is sprayed over the biodiesel. The biodiesel impurities are removed as the water settles to the bottom of the tank. Then, dry washing technique is employed to purify crude biodiesel through the use of ion exchange resins. Dry washing is usually carried out at a temperature of 65C and the process is mostly completed within 20 to 30min. During dry washing, the traces of glycerol are reasonably reduced to appreciable levels. The dry washing procedure is waterless, improves biodiesel quality. Distillation column: The biodiesel purity is brought up to 95wt% at the top product in a distillation column removing residual heavy impurities. The remaining heavy impurities in the bottoms products are treated before being recovered as by-product. Figure 1: Process flow diagram (PFD) for biodiesel production. 4.1 INPUT OUTPUT DATA Time series dynamic data will be provided to each group which consists of relation between manipulated variable to the controlled variable in the process. Please refer to Excel file provided for each group. Blenerane to Mrain Colane

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts