Question: Submit online. For this homework, you will use either Excel or EES to simulate the system, calculating pipe pressure loss and fitting pressure loss. You

Submit online. For this homework, you will use either Excel or EES to simulate the system,

calculating pipe pressure loss and fitting pressure loss. You will also simulate the system to estimate

flow rates in the components.

Creeping bentgrass is used for putting greens on premier courses. Bentgrass is a cool climate grass,

and we are at the southern edge of where it can grow. In recent years, some golf courses have

installed "greens cooling systems" that circulate chilled water in tubing beneath the greens' surface

to improve the grass quality. As far as I know, these systems have used custom airtowater chillers

airtowater heat pumps. It may also be desirable to provide turf heating under some conditions,

so a reversible heat pump may be favored over a chiller

Such a system is being installed for Karsten Creek. Rather than using airtowater heat pumps, which

can be noisy and inefficient, watertowater heat pumps are being used. Closedloop groundsource

heat pump systems are being installed for each putting green. The system shown in Figure has

the following proposed components on the sourceside. For this homework, we won't consider the

loadside the tubing that cools the greens.

For this homework, we will consider a "laboratoryscale" system that could be used for experiments

and model validation. Rather than conditioning a fullsize putting green, we will design a system

that could be used with a smaller putting green

Watertowater heat pump. For this homework, we are using a ClimateMaster Tranquility

WatertoWater heat pump, model TMW This is expected to be able to condition about

sq ft of greens this would be one of multiple systems used to condition the greens.

The proposed design flow rate is GPM; the heat pump entering fluid temperature on the

about Note the TMW performance data on page of the submittal set PDF is for

water. As shown on page the pressure drop with methanol is higher than for

water

Working fluid. methanol antifreeze is being used. You may assume a mean fluid

temperature of

Boreholes. The original plan was to drill two feet boreholes with Utubes, but

instead we ended up with the closer to the heat pump borehole being deep and the

farther borehole being deep.

Connecting piping. Figure shows a layout for the piping. The dimensions are: ;

The horizontal connecting piping between the heat pump and the first borehole is

SDR HDPE. The horizontal connecting piping between the first and second boreholes is

SDR HDPE

Circulating pumps To be selected

To receive full credit on this assignment, you must: Number each section exactly matching the

numbering below, and present everything for that section in the section. Do not put figures at the

end of the document; do not use appendices. Everything for each section has to be presented in

that section. Provide sufficient but brief narrative of how you arrived at each solution, showing

work as needed. It should be possible for the person grading your assignment to quickly ascertain

your methodology without reading your mind. present your work legibly if your handwriting is

not considerably neater than Dr Spitler's you should do it all in Word and Excel! Any scanned work

has to be clearly readable.

Develop a simple model for the heat pump pressure loss. Explain your model and

prepare a plot showing the model behavior and the manufacturer's data points,

corrected for the actual methanol concentration.

Find the values for the fittings and summarize in a table. I've labeled the fittings

that you will include in Table In the table, show the fitting code, diameter, K value

and design flow rate. Fitting codes are EU etc. For T and T please

indicate straight or branch, egTbranch". We will consider elbows, tees, and U

bends. Reducers and expanders are needed, but their head loss is very small, so we

will neglect them. You may assume the tees are diameter and the

reducersexpanders are on the heat pump side of the tees.

Determine the required head of a pump that will give a total flow of GPM

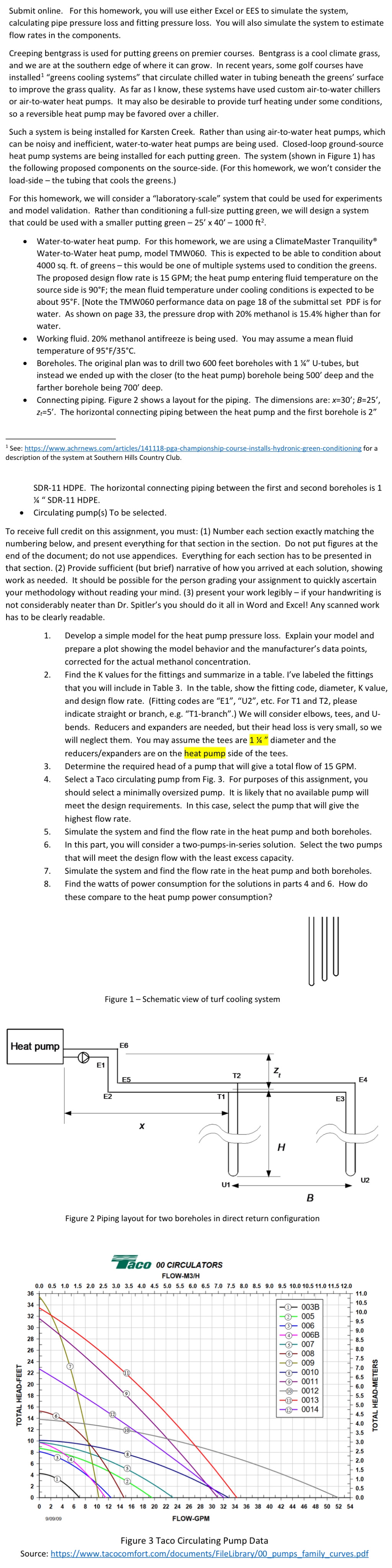

Select a Taco circulating pump from Fig. For purposes of this assignment, you

should select a minimally oversized pump. It is likely that no available pump wi

meet the design requirements. In this case, select the pump

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock