Question: SUNSET MANUFACTURING a An example of how even a small business can adopt lean production principles in order to realise significant improvements is found at

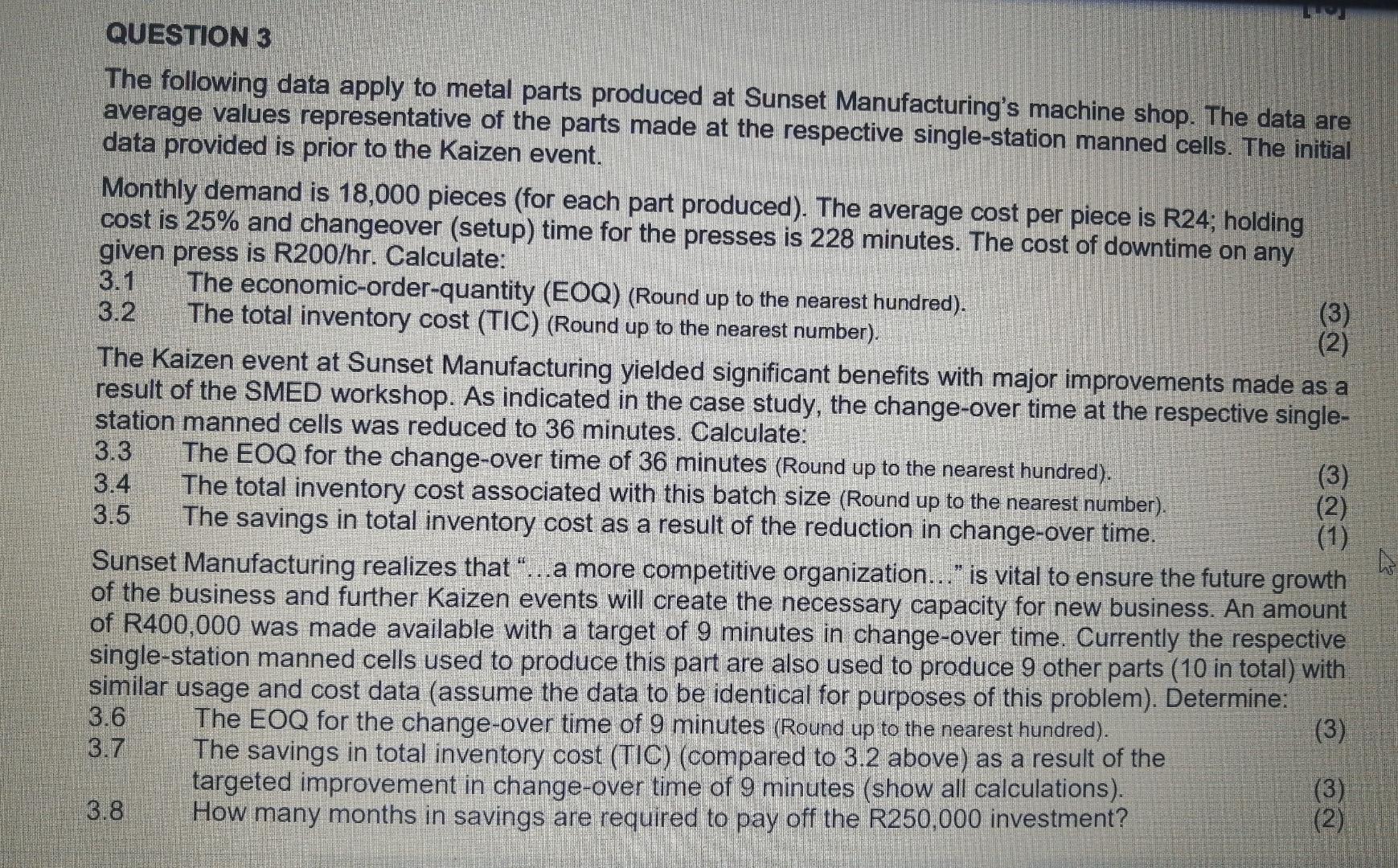

SUNSET MANUFACTURING a An example of how even a small business can adopt lean production principles in order to realise significant improvements is found at Sunset Manufacturing Inc. A 35-person, family owned machine shop. Because of competitive pressures and a business downturn, Sunset began to look for ways to simplify operations and cut costs. At a Kaizen event, it determined that SMED and the 5S approach could yield benefits. Several actions were taken including: Standardizing parts across milling machines Reorganizing the tool room Incorporating the SMED approach in machine setups, and Implementing what was termed "dance cards that gave the operators the specific steps required for SMED of various machines and products. I The results were impressive and gratifying. Tool preparation time dropped from an average of 30 minutes to less than 10 minutes, isolation and identification of worn tools was improved, safety and appearance in the tool room due to 5S application was apparent, machine setup time was reduced from an average of 216 minutes to 36 minutes (an 86 percent improvement), and the entire Kaizen event resulted in an estimated savings of R330 000 per year, with a cost to implement of less than half of that amount. The net impact was to allow smaller lot sizes to be run, a 75 percent reduction in setup scrap, a more competitive organization to emerge and a morale boost for team members. Source: Evans, J.R., Collier, D.A., 2017. Operations Management: An Integrated Goods and Services Approach. Mason USA: Thomson sa The relation QUESTION 3 The following data apply to metal parts produced at Sunset Manufacturing's machine shop. The data are average values representative of the parts made at the respective single-station manned cells. The initial data provided is prior to the Kaizen event. Monthly demand is 18,000 pieces (for each part produced). The average cost per piece is R24; holding cost is 25% and changeover (setup) time for the presses is 228 minutes. The cost of downtime on any given press is R200/hr. Calculate: 3.1 The economic-order-quantity (EOQ) (Round up to the nearest hundred). 3.2 The total inventory cost (TIC) (Round up to the nearest number). (2) The Kaizen event at Sunset Manufacturing yielded significant benefits with major improvements made as a result of the SMED workshop. As indicated in the case study, the change-over time at the respective single- station manned cells was reduced to 36 minutes. Calculate: 3.3 The EOQ for the change-over time of 36 minutes (Round up to the nearest hundred). (3) 3.4 The total inventory cost associated with this batch size (Round up to the nearest number). (2) 3.5 The savings in total inventory cost as a result of the reduction in change-over time. (1) Sunset Manufacturing realizes that.. a more competitive organization..." is vital to ensure the future growth of the business and further Kaizen events will create the necessary capacity for new business. An amount of R400,000 was made available with a target of 9 minutes in change-over time. Currently the respective single-station manned cells used to produce this part are also used to produce 9 other parts (10 in total) with similar usage and cost data (assume the data to be identical for purposes of this problem). Determine: 3.6 The EOQ for the change-over time of 9 minutes (Round up to the nearest hundred). (3) 3.7 The savings in total inventory cost (TIC) (compared to 3.2 above) as a result of the targeted improvement in change-over time of 9 minutes (show all calculations). (3) 3.8 How many months in savings are required to pay off the R250,000 investment? (2) SUNSET MANUFACTURING a An example of how even a small business can adopt lean production principles in order to realise significant improvements is found at Sunset Manufacturing Inc. A 35-person, family owned machine shop. Because of competitive pressures and a business downturn, Sunset began to look for ways to simplify operations and cut costs. At a Kaizen event, it determined that SMED and the 5S approach could yield benefits. Several actions were taken including: Standardizing parts across milling machines Reorganizing the tool room Incorporating the SMED approach in machine setups, and Implementing what was termed "dance cards that gave the operators the specific steps required for SMED of various machines and products. I The results were impressive and gratifying. Tool preparation time dropped from an average of 30 minutes to less than 10 minutes, isolation and identification of worn tools was improved, safety and appearance in the tool room due to 5S application was apparent, machine setup time was reduced from an average of 216 minutes to 36 minutes (an 86 percent improvement), and the entire Kaizen event resulted in an estimated savings of R330 000 per year, with a cost to implement of less than half of that amount. The net impact was to allow smaller lot sizes to be run, a 75 percent reduction in setup scrap, a more competitive organization to emerge and a morale boost for team members. Source: Evans, J.R., Collier, D.A., 2017. Operations Management: An Integrated Goods and Services Approach. Mason USA: Thomson sa The relation QUESTION 3 The following data apply to metal parts produced at Sunset Manufacturing's machine shop. The data are average values representative of the parts made at the respective single-station manned cells. The initial data provided is prior to the Kaizen event. Monthly demand is 18,000 pieces (for each part produced). The average cost per piece is R24; holding cost is 25% and changeover (setup) time for the presses is 228 minutes. The cost of downtime on any given press is R200/hr. Calculate: 3.1 The economic-order-quantity (EOQ) (Round up to the nearest hundred). 3.2 The total inventory cost (TIC) (Round up to the nearest number). (2) The Kaizen event at Sunset Manufacturing yielded significant benefits with major improvements made as a result of the SMED workshop. As indicated in the case study, the change-over time at the respective single- station manned cells was reduced to 36 minutes. Calculate: 3.3 The EOQ for the change-over time of 36 minutes (Round up to the nearest hundred). (3) 3.4 The total inventory cost associated with this batch size (Round up to the nearest number). (2) 3.5 The savings in total inventory cost as a result of the reduction in change-over time. (1) Sunset Manufacturing realizes that.. a more competitive organization..." is vital to ensure the future growth of the business and further Kaizen events will create the necessary capacity for new business. An amount of R400,000 was made available with a target of 9 minutes in change-over time. Currently the respective single-station manned cells used to produce this part are also used to produce 9 other parts (10 in total) with similar usage and cost data (assume the data to be identical for purposes of this problem). Determine: 3.6 The EOQ for the change-over time of 9 minutes (Round up to the nearest hundred). (3) 3.7 The savings in total inventory cost (TIC) (compared to 3.2 above) as a result of the targeted improvement in change-over time of 9 minutes (show all calculations). (3) 3.8 How many months in savings are required to pay off the R250,000 investment? (2)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock