Question: Supply Chain Logistics Management Problem 1. (Chapter 4: Logisties/Supply Chain Customer Service) A food company is attempting to set the customer service level (in-stock probability

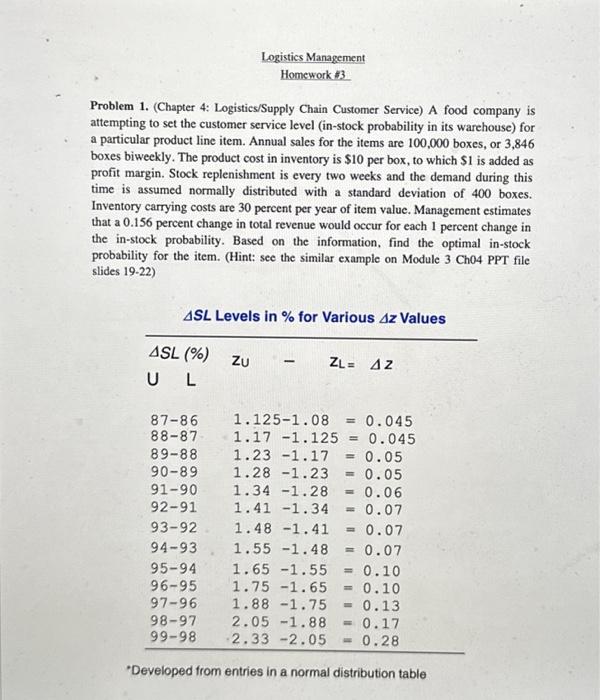

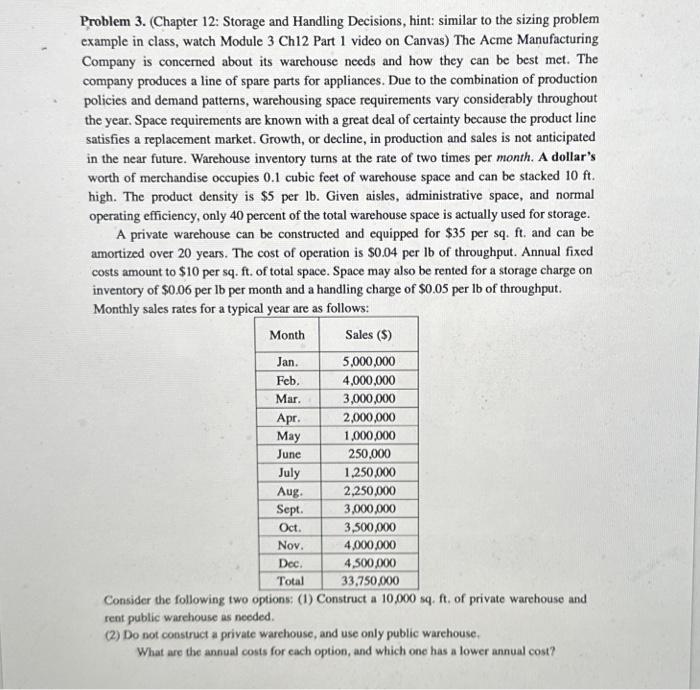

Problem 1. (Chapter 4: Logisties/Supply Chain Customer Service) A food company is attempting to set the customer service level (in-stock probability in its warehouse) for a particular product line item. Annual sales for the items are 100,000 boxes, or 3,846 boxes biweekly. The product cost in inventory is $10 per box, to which $1 is added as profit margin. Stock replenishment is every two weeks and the demand during this time is assumed normally distributed with a standard deviation of 400 boxes. Inventory carrying costs are 30 percent per year of item value. Management estimates that a 0.156 percent change in total revenue would occur for each 1 percent change in the in-stock probability. Based on the information, find the optimal in-stock probability for the item. (Hint: see the similar example on Module 3 Ch04 PPT file slides 19-22) SL Levels in \% for Various z Values -Developed from entries in a normal distribution table Problem 2. (Chapter 11: The Storage and Handling System) Compare the construct private ownership of storage space to rented storage space with reference to the following: a. Services that can be realized from each b. Cost for storage c. Degree of administrative control d. Flexibility in meeting future uncertainties Under what general circumstances is private warehousing a better choice than public warehousing? Problem 3. (Chapter 12: Storage and Handling Decisions, hint: similar to the sizing problem example in class, watch Module 3 Ch12 Part 1 video on Canvas) The Acme Manufacturing Company is concerned about its warehouse needs and how they can be best met. The company produces a line of spare parts for appliances. Due to the combination of production policies and demand patterns, warehousing space requirements vary considerably throughout the year. Space requirements are known with a great deal of certainty because the product line satisfies a replacement market. Growth, or decline, in production and sales is not anticipated in the near future. Warehouse inventory turns at the rate of two times per month. A dollar's worth of merchandise occupies 0.1 cubic feet of warehouse space and can be stacked 10ft. high. The product density is $5 per lb. Given aisles, administrative space, and normal operating efficiency, only 40 percent of the total warehouse space is actually used for storage. A private warehouse can be constructed and equipped for $35 per sq. ft. and can be amortized over 20 years. The cost of operation is $0.04 per lb of throughput. Annual fixed costs amount to $10 per sq. ft. of total space. Space may also be rented for a storage charge on inventory of $0.06 per lb per month and a handling charge of $0.05 per lb of throughput. Monthly sales rates for a typical year are as follows: Consider the following two options: (1) Construct a 10,000sq. ft. of private warehouse and rent public warchouse as needed. (2) Do not construct a private warehouse, and use only public warehouse. What are the annual costs for each option, and which one has a lower annual cost? Problem 1. (Chapter 4: Logisties/Supply Chain Customer Service) A food company is attempting to set the customer service level (in-stock probability in its warehouse) for a particular product line item. Annual sales for the items are 100,000 boxes, or 3,846 boxes biweekly. The product cost in inventory is $10 per box, to which $1 is added as profit margin. Stock replenishment is every two weeks and the demand during this time is assumed normally distributed with a standard deviation of 400 boxes. Inventory carrying costs are 30 percent per year of item value. Management estimates that a 0.156 percent change in total revenue would occur for each 1 percent change in the in-stock probability. Based on the information, find the optimal in-stock probability for the item. (Hint: see the similar example on Module 3 Ch04 PPT file slides 19-22) SL Levels in \% for Various z Values -Developed from entries in a normal distribution table Problem 2. (Chapter 11: The Storage and Handling System) Compare the construct private ownership of storage space to rented storage space with reference to the following: a. Services that can be realized from each b. Cost for storage c. Degree of administrative control d. Flexibility in meeting future uncertainties Under what general circumstances is private warehousing a better choice than public warehousing? Problem 3. (Chapter 12: Storage and Handling Decisions, hint: similar to the sizing problem example in class, watch Module 3 Ch12 Part 1 video on Canvas) The Acme Manufacturing Company is concerned about its warehouse needs and how they can be best met. The company produces a line of spare parts for appliances. Due to the combination of production policies and demand patterns, warehousing space requirements vary considerably throughout the year. Space requirements are known with a great deal of certainty because the product line satisfies a replacement market. Growth, or decline, in production and sales is not anticipated in the near future. Warehouse inventory turns at the rate of two times per month. A dollar's worth of merchandise occupies 0.1 cubic feet of warehouse space and can be stacked 10ft. high. The product density is $5 per lb. Given aisles, administrative space, and normal operating efficiency, only 40 percent of the total warehouse space is actually used for storage. A private warehouse can be constructed and equipped for $35 per sq. ft. and can be amortized over 20 years. The cost of operation is $0.04 per lb of throughput. Annual fixed costs amount to $10 per sq. ft. of total space. Space may also be rented for a storage charge on inventory of $0.06 per lb per month and a handling charge of $0.05 per lb of throughput. Monthly sales rates for a typical year are as follows: Consider the following two options: (1) Construct a 10,000sq. ft. of private warehouse and rent public warchouse as needed. (2) Do not construct a private warehouse, and use only public warehouse. What are the annual costs for each option, and which one has a lower annual cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts