Question: Supply Chain Management Case Study: eGo is an electric scooter manufacturer in Texas. The plant currently employs 80 workers who operate for 22 days a

Supply Chain Management

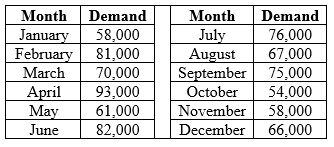

Case Study: eGo is an electric scooter manufacturer in Texas. The plant currently employs 80 workers who operate for 22 days a month, eight hours each day. Workers are paid $12 per hour for normal working hours and $18 per hour for overtime. Overtime is limited to a maximum of 25 hours per month per employee. One worker can assemble a scooter every 12 minutes. Component costs for each scooter is $40. Carrying inventory from one month to the next incurs a cost of $5 per scooter per month. Assume the starting inventory of 24,500 units and eGo wants to end the year with the same level of inventory. eGo is making production plans for the coming year. Below table shows the forecasted monthly demand.

Question:

Discuss how eGo can respond to predictable demand variability by managing supply and demand. (Hint: Relate to the sales and operations planning strategies)

Month January February March April May June Demand 58,000 81,000 70,000 93,000 61,000 82,000 Month Demand July 76,000 August 67.000 September 75,000 October 54.000 November 58,000 December 66,000

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts