Question: Supply chain management (Demand forecasting) Based on the demand forecasting provided in the attached Excel spreadsheet: Economies of scale: determine the optimal ordering quantity for

Supply chain management (Demand forecasting)

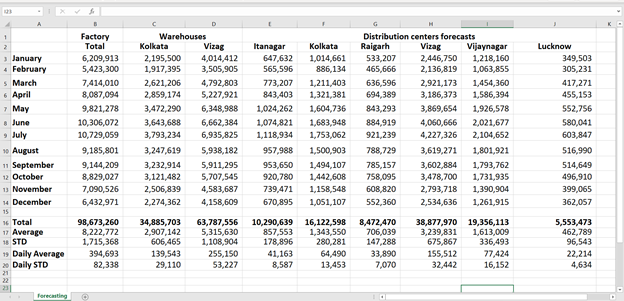

- Based on the demand forecasting provided in the attached Excel spreadsheet:

- Economies of scale:

- determine the optimal ordering quantity for each warehouse and its related inventory costs.

- determine the optimal production quantity for the plant and its related inventory costs.

- propose an economies of scale policy for the company. Please justify the proposed policy.

- Safety stocks:

- determine the safety stocks required for the following service levels: 99%, 90% and 85%.

- Determine the total cost of the safety stocks.

- Calculate the expected penalties for each service level.

- propose a safety stock policy service level. Please justify the proposed policy.

- Economies of scale:

- What should SSF Inc. do to implement a sustainable inventory management strategy?

Given below are the details of SSF Inc company:

SSF Inc. is a Seafood company based in Bhuvneshwar and specialized in a conditioned and canned table ready seafood products. The company was founded in the late seventies by Mr. Shailesh as a family business. Today the company owns a manufacturing plant in Bhuvneshwar and two distribution centers; one in Vizag and another one located in the Kolkata urban region. Over the years, Mr. Shailesh built stable business relationships with the major food retail chains in the Country.

The company produces seafood cans, which are packaged in cardboard boxes containing 200 cans, with an average production cost of $200/box. The company profit margin on each box sold is 65% of the production cost. SSF Inc. pays a 15% penalty of the sale price (production plus profit) for any portion of unfulfilled orders.

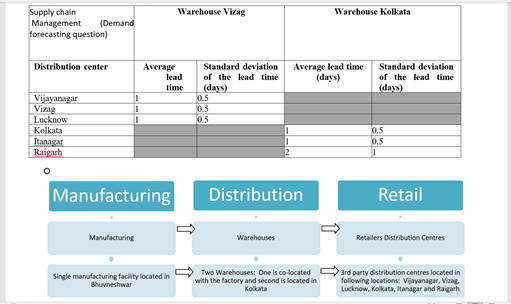

The ordering cost from any of the warehouses to the plant is on average $1,500/order. However, the factory production setup process usually cost more than $250,000 to completely shut down the factory for more than a week and restart it again. The annual holding cost at any of the two warehouses is estimated at $200/box. The factory requires about five business days lead time to change production schedule. The company operates 250 days/year with a maximum production capacity of about 2000 boxes/day at the end of 2020. The lead times and their standard deviations are provided in the following table:

Warehouse Vizag Warehouse Kolkata Supply chain Management (Demand forecasting question) Distribution center Average lead time Average lead time (days) Standard deviation of the lead time (days) 0.5 0.5 0.5 Standard deviation of the lead time (days) 1 1 Vijayanagar Vizag Lucknow Kolkata Itanagar Raigarh 0.5 0.5 1 Manufacturing Distribution Retail Manufacturing Warehouses Retailers Distribution Centres Single manufacturing facility located in Bhuvneshwar Two Warehouses: One is co-located 3rd party distribution centres located in with the factory and second is located in following locations Vijayanagar, Vizag Kolkata Lucknow, Kolkata, Itanagar and Raigarh 1 2 January 4 February 5 March 6 April 7 May 8 June July 10 August 11 September 12 October 13 November 14 December 15 Total 17 Average 18 STD 19 Daily Average 2. Daily STD 21 Factory Total 6,209,913 5,423,300 7,414,010 8,087,094 9,821,278 10,306,072 10,729,059 9,185,801 9,144,209 8,829,027 7,090,526 6,432,971 Warehouses Kolkata Vizag 2,195,500 4,014,412 1,917,395 3,505,905 2,621,206 4,792,803 2,859,174 5,227,921 3,472,290 6,348,988 3,643,688 6,662,384 3,793,234 6,935,825 3,247,619 5,938,182 3,232,914 5,911,295 3,121,482 5,707,545 2,506,839 4,583,687 2,274,362 4,158,609 Itanagar 647,632 565,596 773,207 843,403 1,024.262 1,074,821 1,118,934 957,988 953,650 920,780 739,471 670,895 Kolkata 1,014,661 886,134 1,211,403 1,321,381 1,604,736 1,683,948 1,753,062 1,500,903 1,494,107 1,442,608 1,158,548 1,051,107 Distribution centers forecasts Raigarh Vizag Vijaynagar 533,207 2,446,750 1,218,160 465,666 2,136,819 1,063,855 636,596 2,921,173 1,454,360 694,389 3,186,373 1,586,394 843,293 3,869,654 1,926,578 884,919 4,060,666 2,021,677 921,239 4,227,326 2,104,652 788,729 3,619,271 1,801,921 785,157 3,602,884 1,793,762 758,095 3,478,700 1,731,935 608,820 2,793,718 1,390,904 552,360 2,534,636 1,261,915 Lucknow 349,503 305,231 417,271 455,153 552,756 580,041 603,847 516,990 514,649 496,910 399,065 362,057 98,673,260 8,222,772 1,715,368 394,693 82,338 34,885,703 2,907,142 606,465 139,543 29.110 63,787,556 5,315,630 1,108,904 255,150 53,227 10,290,639 857,553 178,896 41,163 8,587 16,122,598 1,343,550 280,281 64,490 13,453 8,472,470 706,039 147,288 33,890 7,070 38,877,970 19,356,113 3,239,831 1,613,009 675,867 336,493 155,512 77.424 32,442 16,152 5,553,473 462,789 96,543 22,214 4,634 231 Forecasting Warehouse Vizag Warehouse Kolkata Supply chain Management (Demand forecasting question) Distribution center Average lead time Average lead time (days) Standard deviation of the lead time (days) 0.5 0.5 0.5 Standard deviation of the lead time (days) 1 1 Vijayanagar Vizag Lucknow Kolkata Itanagar Raigarh 0.5 0.5 1 Manufacturing Distribution Retail Manufacturing Warehouses Retailers Distribution Centres Single manufacturing facility located in Bhuvneshwar Two Warehouses: One is co-located 3rd party distribution centres located in with the factory and second is located in following locations Vijayanagar, Vizag Kolkata Lucknow, Kolkata, Itanagar and Raigarh 1 2 January 4 February 5 March 6 April 7 May 8 June July 10 August 11 September 12 October 13 November 14 December 15 Total 17 Average 18 STD 19 Daily Average 2. Daily STD 21 Factory Total 6,209,913 5,423,300 7,414,010 8,087,094 9,821,278 10,306,072 10,729,059 9,185,801 9,144,209 8,829,027 7,090,526 6,432,971 Warehouses Kolkata Vizag 2,195,500 4,014,412 1,917,395 3,505,905 2,621,206 4,792,803 2,859,174 5,227,921 3,472,290 6,348,988 3,643,688 6,662,384 3,793,234 6,935,825 3,247,619 5,938,182 3,232,914 5,911,295 3,121,482 5,707,545 2,506,839 4,583,687 2,274,362 4,158,609 Itanagar 647,632 565,596 773,207 843,403 1,024.262 1,074,821 1,118,934 957,988 953,650 920,780 739,471 670,895 Kolkata 1,014,661 886,134 1,211,403 1,321,381 1,604,736 1,683,948 1,753,062 1,500,903 1,494,107 1,442,608 1,158,548 1,051,107 Distribution centers forecasts Raigarh Vizag Vijaynagar 533,207 2,446,750 1,218,160 465,666 2,136,819 1,063,855 636,596 2,921,173 1,454,360 694,389 3,186,373 1,586,394 843,293 3,869,654 1,926,578 884,919 4,060,666 2,021,677 921,239 4,227,326 2,104,652 788,729 3,619,271 1,801,921 785,157 3,602,884 1,793,762 758,095 3,478,700 1,731,935 608,820 2,793,718 1,390,904 552,360 2,534,636 1,261,915 Lucknow 349,503 305,231 417,271 455,153 552,756 580,041 603,847 516,990 514,649 496,910 399,065 362,057 98,673,260 8,222,772 1,715,368 394,693 82,338 34,885,703 2,907,142 606,465 139,543 29.110 63,787,556 5,315,630 1,108,904 255,150 53,227 10,290,639 857,553 178,896 41,163 8,587 16,122,598 1,343,550 280,281 64,490 13,453 8,472,470 706,039 147,288 33,890 7,070 38,877,970 19,356,113 3,239,831 1,613,009 675,867 336,493 155,512 77.424 32,442 16,152 5,553,473 462,789 96,543 22,214 4,634 231 Forecasting

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts