Question: Supply chain management question. Below is a Spend Analysis that you and your team prepared of the raw and packing materials and MRO that you

Supply chain management question.

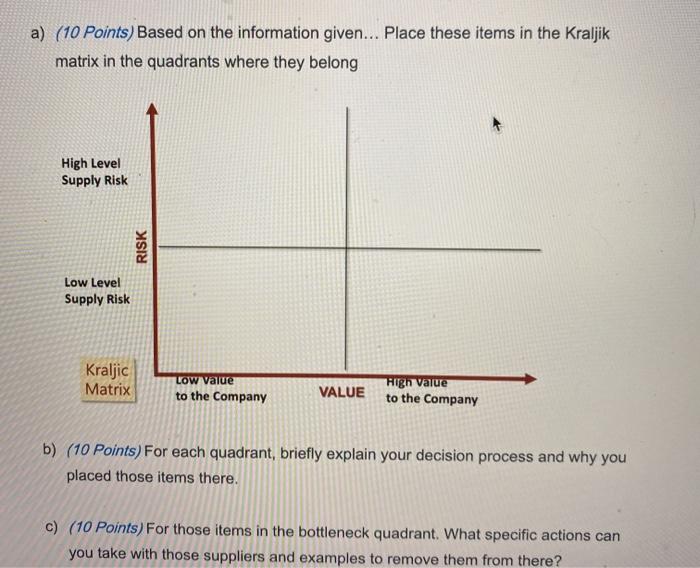

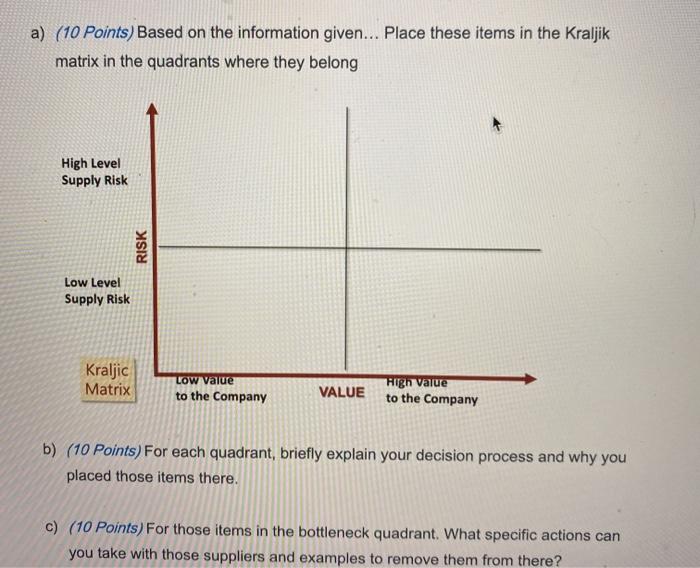

Below is a Spend Analysis that you and your team prepared of the raw and packing materials and MRO that you buy on a regular basis and including the supply/market conditions for each of them 1. Sugar - Commodity material, several qualified suppliers and markets to buy from. Large volume and Spend II. Dextrose - Small Spend because although several suppliers offer it you buy a small amount only once a quarter III. Citric acid - Chemical that is only produced by one supplier located in a different country. Not really a big Spend, but it deliveries do not happen as planned it cannot be replaced by other materials. IV. Salt - Commodity material, several qualified suppliers and markets to buy from, but really low cost V. Flavors - Key component that determines the identity" of your product. People buy your drink because of this. These flavors were developed by a Global Flavor house that helps you test them and pick the right ones VI. PET Bottles - One of your largest items in volume and spend. However you have 4 different suppliers that you alternate and perform similarly in quality, cost and service VII. Plastic Bottle Caps - You buy this from only one supplier, because they are the only ones that have a mold that can make the cap you need. They have other customers that use this same cap and that can be a problem sometimes VIII. Plastic Labels - Another large spend, you rely on a single supplier that can make many different color combinations and unique designs and respond very fast to the innovations you bring to the market . Your last collaboration was a holographic label for a new product that is now your #1 selling item IX. Cardboard Tray - Significant Spend given the large volume, many suppliers qualified, you buy this weekly and you want to target important cost reductions X. Plastic WrapAround film - Similar situation, significant Spend given the larga volume, many suppliers qualified, you buy this weekly and you want to target important cost reductions XI. Lubricants - You have a few alternatives of well-known brands you can buy to use in your machines. It is bought every other month. Relatively low expense XII. Office Paper and Printing ink - Can be bought from several distributors. Small expense compared with the raw and Packaging materials KIII. Spare parts for Making and Filling equipment - Can only be bought from the manufacturers of the equipment. These manufacturers also will provide upgrades that will allow your equipment to run faster and better as they develop improvements a) (10 Points) Based on the information given... Place these items in the Kraljik matrix in the quadrants where they belong High Level Supply Risk RISK Low Level Supply Risk Kraljic Matrix LOW Value to the Company VALUE High value to the Company b) (10 Points) For each quadrant, briefly explain your decision process and why you placed those items there. c) (10 Points) For those items in the bottleneck quadrant. What specific actions can you take with those suppliers and examples to remove them from there

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock