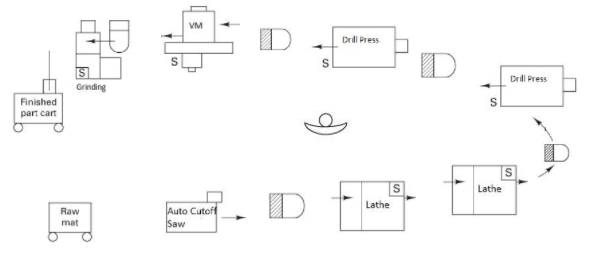

Question: Suppose a lean engineer creates an interim machining cell, run by one operator initially, and the machines are all single-cycle-automatic type (SCA). The cell layout

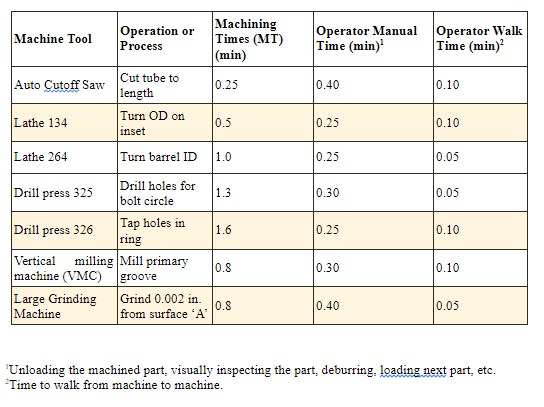

Suppose a lean engineer creates an interim machining cell, run by one operator initially, and the machines are all single-cycle-automatic type (SCA). The cell layout and its operating times are shown below.

1. Assuming this cell is run by one operator, what is the NCT of the cell, in minutes/part?

2. What is the production rate, using your NCT from question 1, in parts/hour?

3. Assume the stock-on-hand (SOH) in this cell consists of one unit at each machine. For now, ignore any WIP in the decouplers. For one part moving through the cell with one operator, what is the throughput (in minutes)? Throughput is often referred to as Lead Time.

VM Drill Press S Drill Press Grinding Finished part cart S Lathe Lathe Raw mat Auto Cutoff Saw Machine Tool Operation or Process Machining Times (MT) (min) Operator Manual Time (min) Operator Walk Time (min) Auto Cutoff Saw 0.25 0.40 0.10 Lathe 134 Cut tube to length Turn OD on inset Turn barrel ID 0.5 0.25 0.10 Lathe 264 1.0 0.25 0.05 1.3 0.30 0.05 1.6 0.25 0.10 Drill holes for Drill 325 press bolt circle Drill press 326 Tap holes in ring Vertical milling Mill primary machine (VMC) groove Large Grinding Grind 0.002 in. Machine from surface 'A 0.8 0.30 0.10 0.8 0.40 0.05 Unloading the machined part, visually inspecting the part, deburring, loading next part, etc. Time to walk from machine to machineStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts