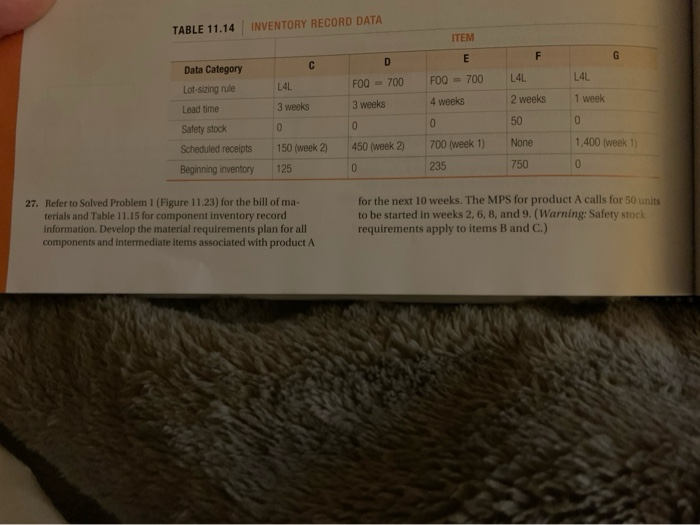

Question: TABLE 11.14 INVENTORY RECORD DATA ITEM G I c D FOQ = 700 3 weeks E FOQ = 700 4 weeks LAL 1 week 3

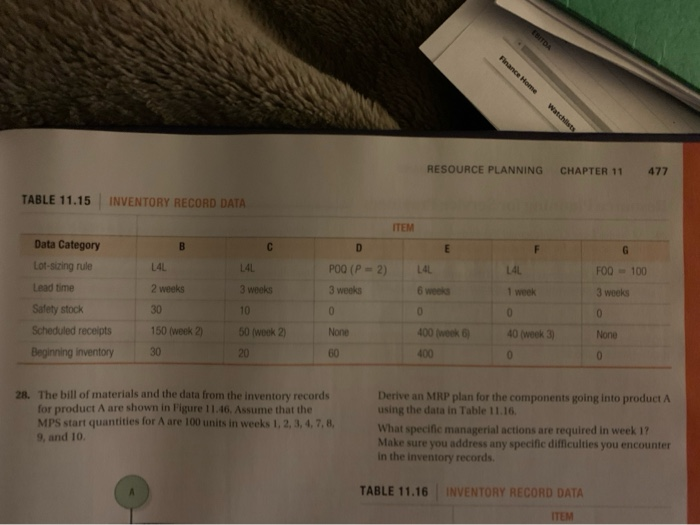

TABLE 11.14 INVENTORY RECORD DATA ITEM G I c D FOQ = 700 3 weeks E FOQ = 700 4 weeks LAL 1 week 3 weeks Data Category Lot-sizing rule Lead time Safety stock Scheduled receipts Beginning inventory F L4L 2 weeks 500 None 750 450 (week 2) 700 (week 1) 1.400 (week 1) 150 (week 2) 125 0 235 27. Refer to Solved Problem 1 (Figure 11.23) for the bill of ma- terials and Table 11.15 for component inventory record information. Develop the material requirements plan for all components and intermediate items associated with product A for the next 10 weeks. The MPS for product A calls for 50 units to be started in weeks 2, 6, 8, and 9. (Warning: Safety stock requirements apply to items B and C.) RESOURCE PLANNING CHAPTER 11 477 TABLE 11.15 INVENTORY RECORD DATA L4L L4L LAL L4L POQ (P = 2) 3 weeks FOO = 100 3 weeks 2 weeks 3 weeks 1 week Data Category Lot-sizing rule Lead time Safety stock Scheduled receipts Beginning inventory 60 (week 2) None 150 (week 2) 30 40 (week 3) None 400 week 400 60 28. The bill of materials and the data from the inventory records for product A are shown in Figure 11.46. Assume that the MPS start quantities for A are 100 units in weeks 1, 2, 3, 4, 7, 8, 9, and 10 Derive an MRP plan for the components going into product A using the data in Table 11.16. What specific managerial actions are required in week 1? Make sure you address any specific difficulties you encounter in the inventory records. TABLE 11.16 INVENTORY RECORD DATA TABLE 11.14 INVENTORY RECORD DATA ITEM G I c D FOQ = 700 3 weeks E FOQ = 700 4 weeks LAL 1 week 3 weeks Data Category Lot-sizing rule Lead time Safety stock Scheduled receipts Beginning inventory F L4L 2 weeks 500 None 750 450 (week 2) 700 (week 1) 1.400 (week 1) 150 (week 2) 125 0 235 27. Refer to Solved Problem 1 (Figure 11.23) for the bill of ma- terials and Table 11.15 for component inventory record information. Develop the material requirements plan for all components and intermediate items associated with product A for the next 10 weeks. The MPS for product A calls for 50 units to be started in weeks 2, 6, 8, and 9. (Warning: Safety stock requirements apply to items B and C.) RESOURCE PLANNING CHAPTER 11 477 TABLE 11.15 INVENTORY RECORD DATA L4L L4L LAL L4L POQ (P = 2) 3 weeks FOO = 100 3 weeks 2 weeks 3 weeks 1 week Data Category Lot-sizing rule Lead time Safety stock Scheduled receipts Beginning inventory 60 (week 2) None 150 (week 2) 30 40 (week 3) None 400 week 400 60 28. The bill of materials and the data from the inventory records for product A are shown in Figure 11.46. Assume that the MPS start quantities for A are 100 units in weeks 1, 2, 3, 4, 7, 8, 9, and 10 Derive an MRP plan for the components going into product A using the data in Table 11.16. What specific managerial actions are required in week 1? Make sure you address any specific difficulties you encounter in the inventory records. TABLE 11.16 INVENTORY RECORD DATA