Question: table 5 For 2 hours every day, a worker picks up sacks of grain weighing slightly over 12kg from an incoming conveyor belt (75cm above

table 5

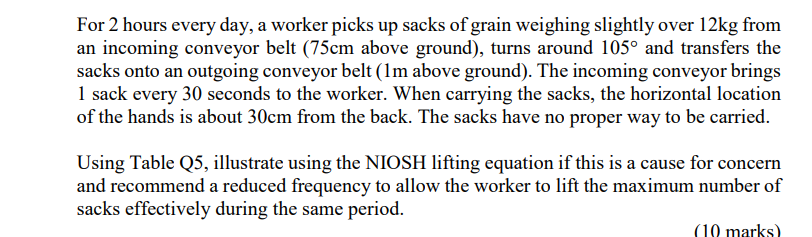

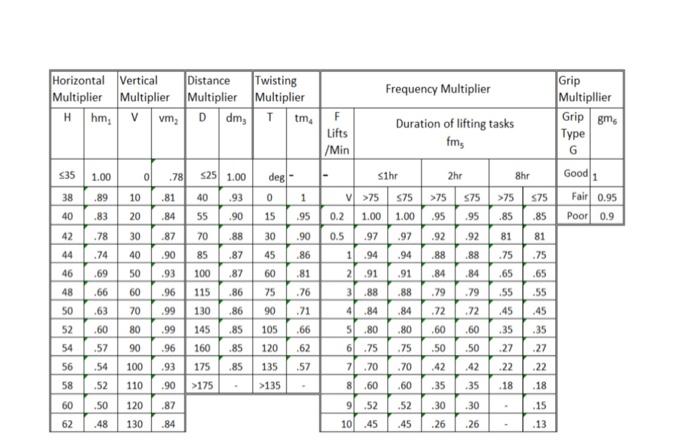

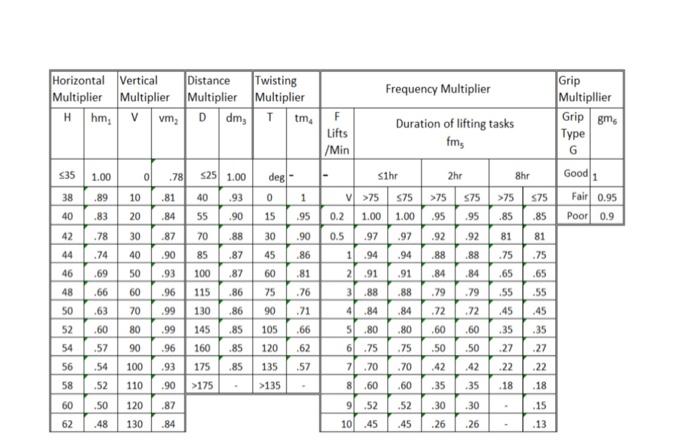

For 2 hours every day, a worker picks up sacks of grain weighing slightly over 12kg from an incoming conveyor belt (75cm above ground), turns around 105 and transfers the sacks onto an outgoing conveyor belt (lm above ground). The incoming conveyor brings 1 sack every 30 seconds to the worker. When carrying the sacks, the horizontal location of the hands is about 30cm from the back. The sacks have no proper way to be carried. Using Table Q5, illustrate using the NIOSH lifting equation if this is a cause for concern and recommend a reduced frequency to allow the worker to lift the maximum number of sacks effectively during the same period. (10 marks) Horizontal Vertical Distance Twisting Multiplier Multiplier Multiplier Multiplier H hm V vm D dmg T tma Frequency Multiplier Grip Multipllier F Lifts /Min Duration of lifting tasks fm Grip gm Type G 535 1.00 0 1 .78 525 1.00 deg Sihr 2hr Good 8hr 38 .89 10 .81 40 93 0 1 V >75 575 >75 575 >75 575 Fair 0.95 Poor 0.9 40 .83 20 .84 55 .90 15 95 0.2 1.00 1.00 .95 .95 .85 .85 42 .78 30 .87 70 .88 30 .90 0.5 97 .97 .92 .92 81 81 44 .74 40 .90 85 .87 45 .86 .94 .88 .88 .75 .75 11.94 2 .91 46 .69 50 .93 100 .87 60 .81 .91 .84 .84 .65 .65 48 .66 60 .96 115 .86 75 .76 3 .88 .88 .79 .79 .55 .55 .45 .63 70 .99 130 86 90 4 .84 .84 .72 45 50 52 .71 .66 .72 .60 .60 80 .99 145 5 .80 b 2 | .60 .35 .85 .85 .35 105 120 80 .75 54 90 .96 160 .62 6 .75 50 .50 .27 .27 .57 .54 56 100 .93 175 .85 135 .57 .70 .42 .42 .22 .22 7.70 8 .60 58 .52 110 .90 >175 >135 .60 .35 .35 .18 .18 60 .50 120 .87 9 .52 .52 .30 .30 .15 62 .48 130 .84 10.45 .45 .26 .26 .13 For 2 hours every day, a worker picks up sacks of grain weighing slightly over 12kg from an incoming conveyor belt (75cm above ground), turns around 105 and transfers the sacks onto an outgoing conveyor belt (lm above ground). The incoming conveyor brings 1 sack every 30 seconds to the worker. When carrying the sacks, the horizontal location of the hands is about 30cm from the back. The sacks have no proper way to be carried. Using Table Q5, illustrate using the NIOSH lifting equation if this is a cause for concern and recommend a reduced frequency to allow the worker to lift the maximum number of sacks effectively during the same period. (10 marks) Horizontal Vertical Distance Twisting Multiplier Multiplier Multiplier Multiplier H hm V vm D dmg T tma Frequency Multiplier Grip Multipllier F Lifts /Min Duration of lifting tasks fm Grip gm Type G 535 1.00 0 1 .78 525 1.00 deg Sihr 2hr Good 8hr 38 .89 10 .81 40 93 0 1 V >75 575 >75 575 >75 575 Fair 0.95 Poor 0.9 40 .83 20 .84 55 .90 15 95 0.2 1.00 1.00 .95 .95 .85 .85 42 .78 30 .87 70 .88 30 .90 0.5 97 .97 .92 .92 81 81 44 .74 40 .90 85 .87 45 .86 .94 .88 .88 .75 .75 11.94 2 .91 46 .69 50 .93 100 .87 60 .81 .91 .84 .84 .65 .65 48 .66 60 .96 115 .86 75 .76 3 .88 .88 .79 .79 .55 .55 .45 .63 70 .99 130 86 90 4 .84 .84 .72 45 50 52 .71 .66 .72 .60 .60 80 .99 145 5 .80 b 2 | .60 .35 .85 .85 .35 105 120 80 .75 54 90 .96 160 .62 6 .75 50 .50 .27 .27 .57 .54 56 100 .93 175 .85 135 .57 .70 .42 .42 .22 .22 7.70 8 .60 58 .52 110 .90 >175 >135 .60 .35 .35 .18 .18 60 .50 120 .87 9 .52 .52 .30 .30 .15 62 .48 130 .84 10.45 .45 .26 .26 .13

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock