Question: Table 5.11 Design Matrix and Tensile Strength Data, Spot time (B), holding time (C), electrode force (D), and machine type (E), each at two levels.

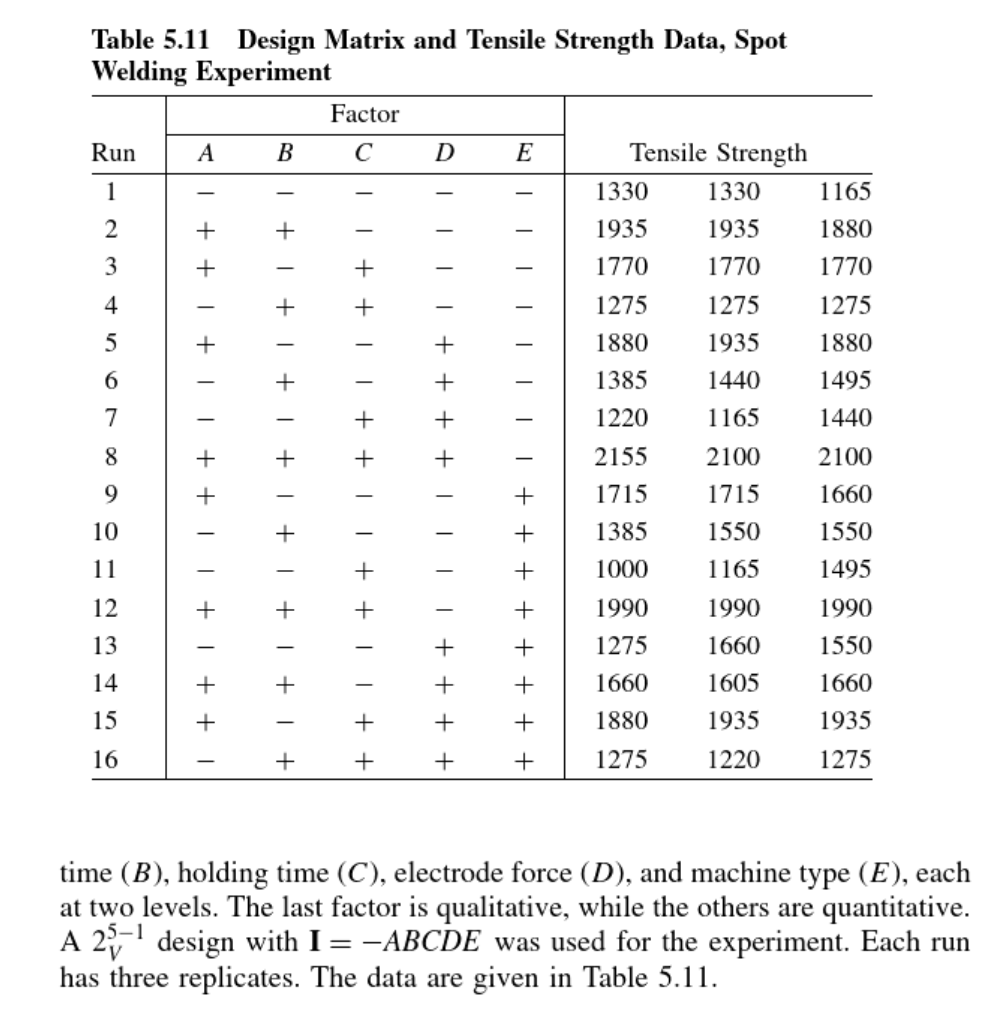

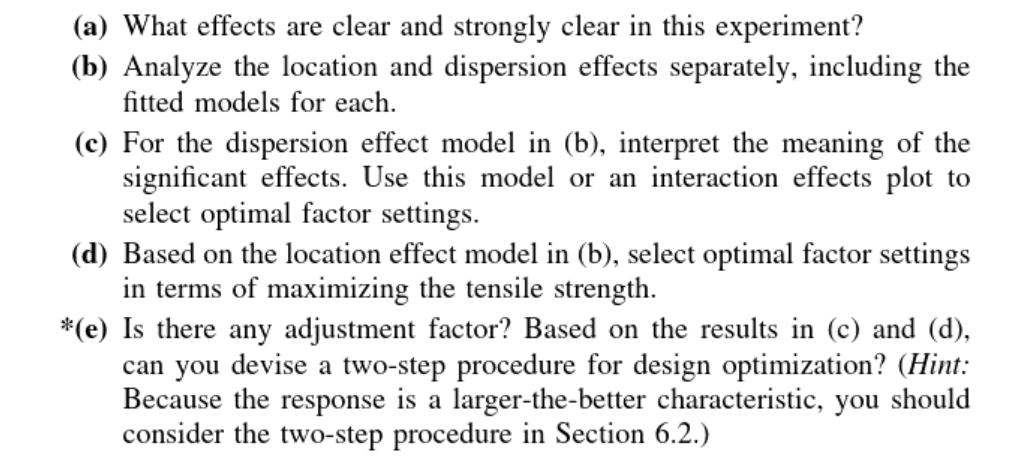

Table 5.11 Design Matrix and Tensile Strength Data, Spot time (B), holding time (C), electrode force (D), and machine type (E), each at two levels. The last factor is qualitative, while the others are quantitative. A 2V51 design with I=ABCDE was used for the experiment. Each run has three replicates. The data are given in Table 5.11. 28. In a resistance spot welding experiment, five factors were chosen to study their effects on the tensile strength, which is the maximum load a weld can sustain in a tensile test. The five factors are: button diameter (A), welding (a) What effects are clear and strongly clear in this experiment? (b) Analyze the location and dispersion effects separately, including the fitted models for each. (c) For the dispersion effect model in (b), interpret the meaning of the significant effects. Use this model or an interaction effects plot to select optimal factor settings. (d) Based on the location effect model in (b), select optimal factor settings in terms of maximizing the tensile strength. *(e) Is there any adjustment factor? Based on the results in (c) and (d), can you devise a two-step procedure for design optimization? (Hint: Because the response is a larger-the-better characteristic, you should consider the two-step procedure in Section 6.2.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts