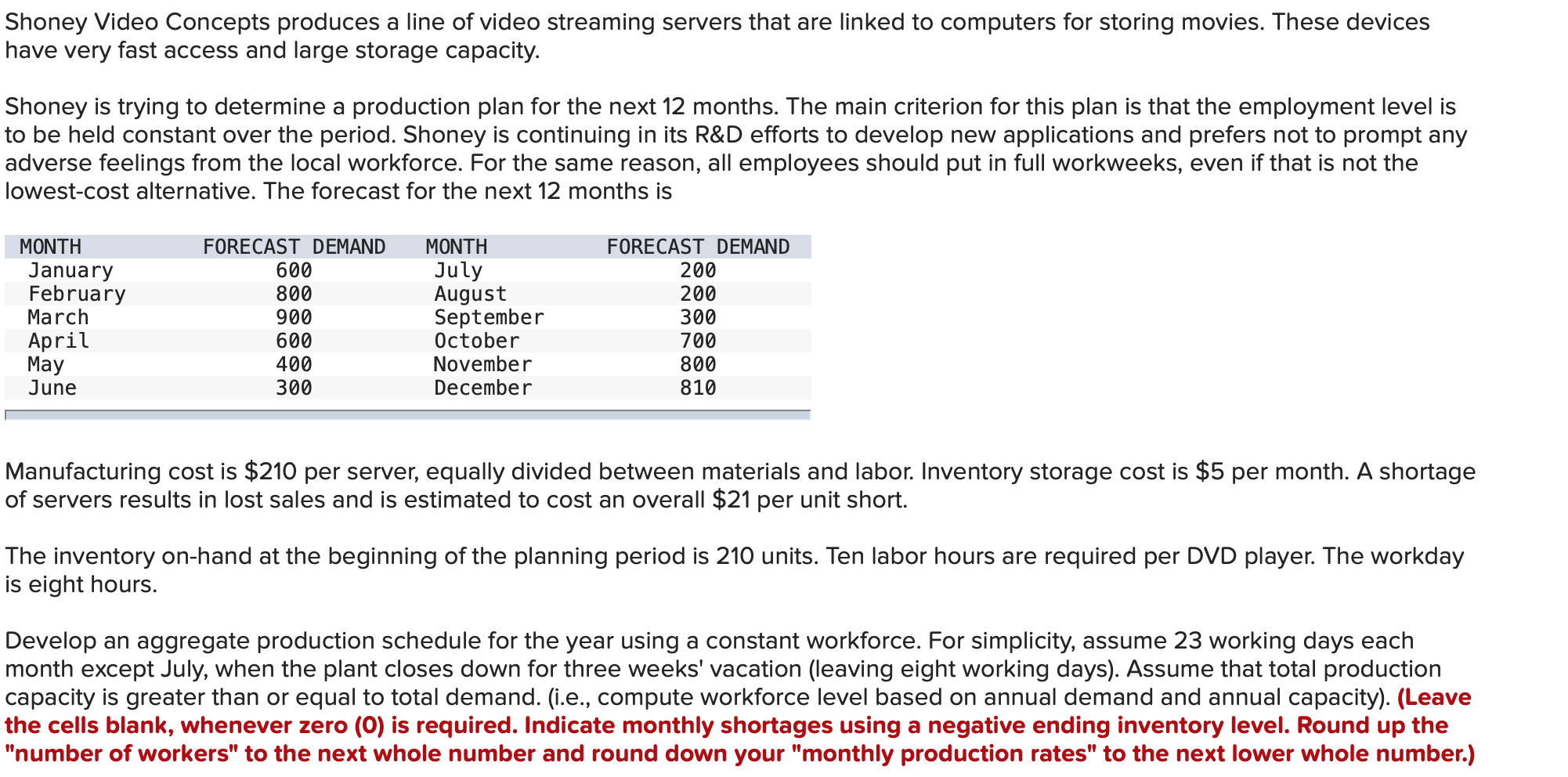

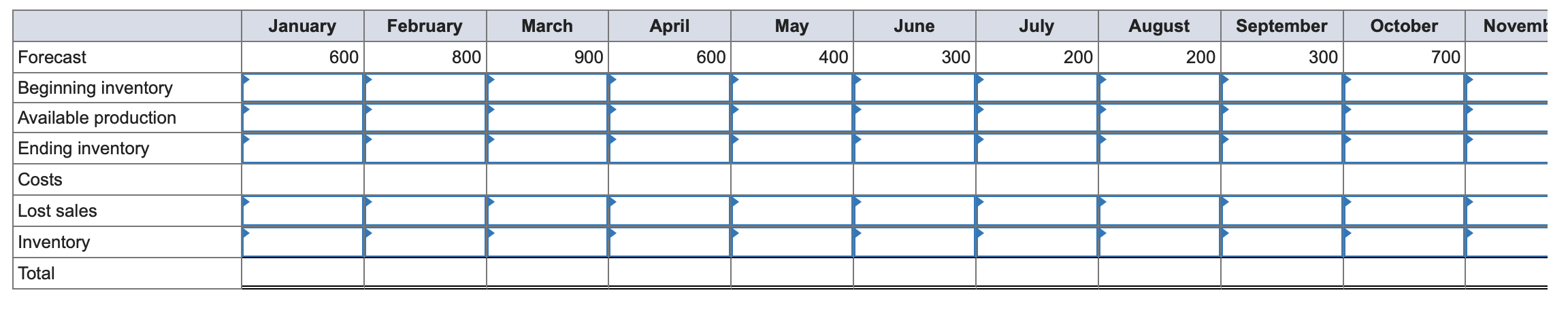

Question: Table needs to go through December but it wouldn't fit on the screenshot Shoney Video Concepts produces a line of video streaming servers that are

Table needs to go through December but it wouldn't fit on the screenshot

Table needs to go through December but it wouldn't fit on the screenshot

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock