Question: The answer is already given below. Just do it on your way to find. plz Three SAE class 9 . 8 steel bolts having a

The answer is already given below. Just do it on your way to find. plz

Three SAE class steel bolts having a specified safety factor are used to attach a bracket o fknown geometry that supports a known vertical load.

Find: Select an appropriate bolt size

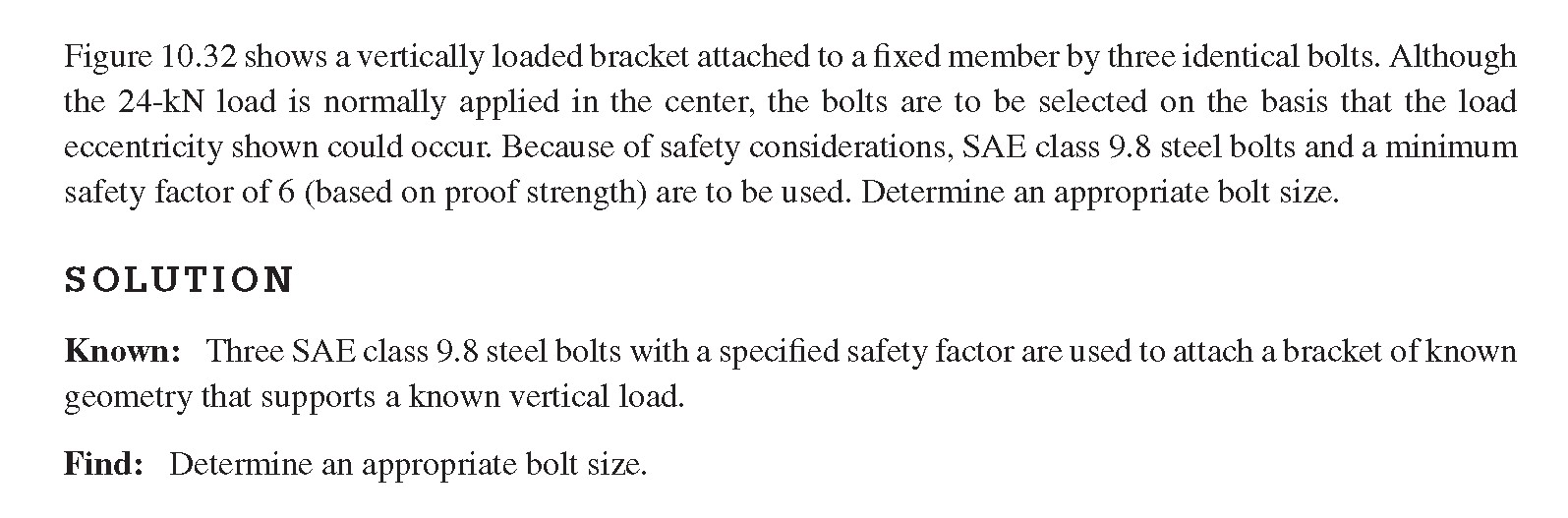

Figure shows a vertically loaded bracket attached to a fixed member by three identical bolts. Although

the load is normally applied in the center, the bolts are to be selected on the basis that the load

eccentricity shown could occur. Because of safety considerations, SAE class steel bolts and a minimum

safety factor of based on proof strength are to be used. Determine an appropriate bolt size.

SOLUTION

Known: Three SAE class steel bolts with a specified safety factor are used to attach a bracket of known

geometry that supports a known vertical load.

Find: Determine an appropriate bolt size. Schematic and Given Data:

FIGURE Vertically loaded bracket

supported by three bolts. Schematic and Given Data: See Sample Problem and Figure

Assumptions:

The shear forces caused by the eccentric vertical load are carried completely by the bolts.

The vertical shear load is distributed equally among the three bolts.

The tangential shear force carried by each bolt is proportional to its distance from the center of gravity

of the group of bolts.

Analysis:

Neglecting friction has no effect on bolt stresses in the threaded region, where attention was focused

on Sample Problem For this problem, attention is shifted to the bolt shear plane at the interface

between bracket and fixed plate This plane experiences the tensile force of kN calculated in

Sample Problem in addition to the shear force calculated in the following step

The applied eccentric shear force of tends to displace the bracket downward and

also rotate it clockwise about the center of gravity of the bolt group cross section. For three bolts of equal

size, the center of gravity corresponds to the centroid of the triangular pattern, as shown in Figure

This figure shows the original applied load dotted vector replaced by an equal load applied at the

centroid solid vector plus a torque that is equal to the product of the force and the distance it was

moved. As assumed, each bolt carries onethird of the vertical shear load, plus a tangential force with

respect to rotation about the center of gravity that is proportional to its distance from the center of

gravity. Calculations on the figure show this tangential force to be kN for each of the top bolts.

The vector sum of the two shear forces is obviously greatest for the upper right bolt. Routine calculation

shows

The critical upper right bolt is thus subjected to a tensile stress, and a shear stress,

Substitution in the distortion energy equation gives an equivalent tensile stress of

Equating this to the proof stress gives

MPa

Therefore,

Finally,

Thus, a shank diameter of mm is required.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock