Question: The answer is not 52.27 per hour . . . Atlas Inc. is a toy bicycle manufacturing company producing a five-inch small version of the

The answer is not 52.27 per hour

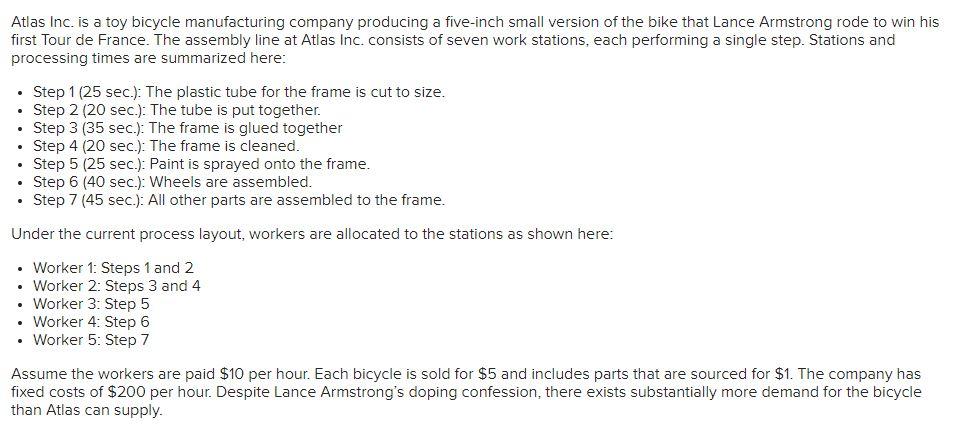

. . . Atlas Inc. is a toy bicycle manufacturing company producing a five-inch small version of the bike that Lance Armstrong rode to win his first Tour de France. The assembly line at Atlas Inc. consists of seven work stations, each performing a single step. Stations and processing times are summarized here: Step 1 (25 sec.): The plastic tube for the frame is cut to size. Step 2 (20 sec.). The tube is put together. Step 3 (35 sec.): The frame is glued together Step 4 (20 sec.): The frame is cleaned. Step 5 (25 sec.): Paint is sprayed onto the frame. Step 6 (40 sec.): Wheels are assembled. Step 7 (45 sec.): All other parts are assembled to the frame. Under the current process layout, workers are allocated to the stations as shown here: Worker 1: Steps 1 and 2 Worker 2: Steps 3 and 4 Worker 3: Step 5 Worker 4: Step 6 . Worker 5: Step 7 Assume the workers are paid $10 per hour. Each bicycle is sold for $5 and includes parts that are sourced for $1. The company has fixed costs of $200 per hour. Despite Lance Armstrong's doping confession, there exists substantially more demand for the bicycle than Atlas can supply. e What would be the profit per hour if Atlas were able to reduce the processing time at the bottleneck by 6 seconds per unit (assume unlimited demand)? $ 52.27 x per hourStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock