Question: THE CASE STUDY CONTINUES IN THE NEXT QUESTION Adobe PDF Signatures Question B Taking into account the 'George Wilson Industries' case study discussed in class,

THE CASE STUDY CONTINUES IN THE NEXT QUESTION

THE CASE STUDY CONTINUES IN THE NEXT QUESTION

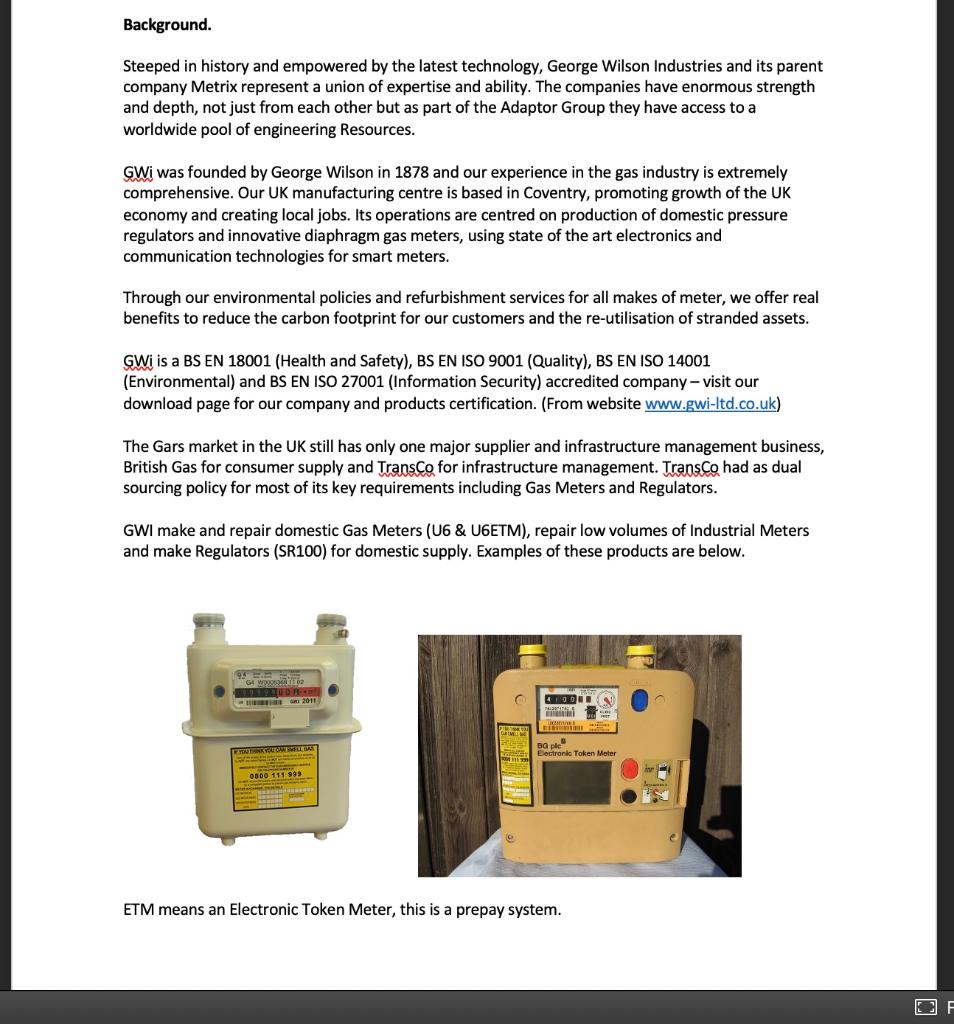

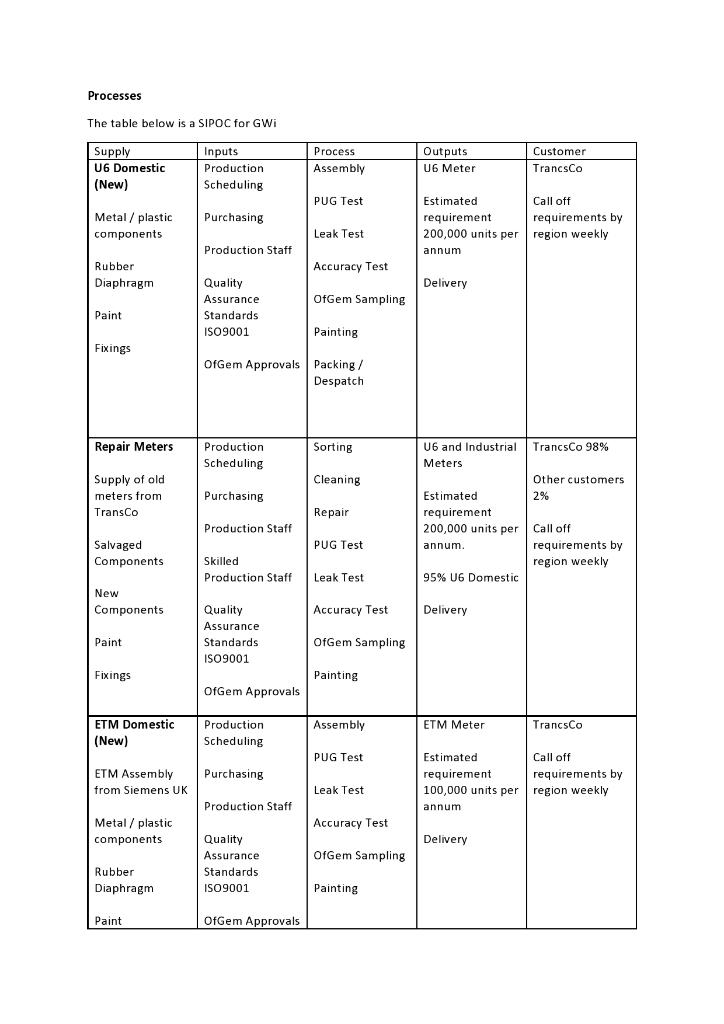

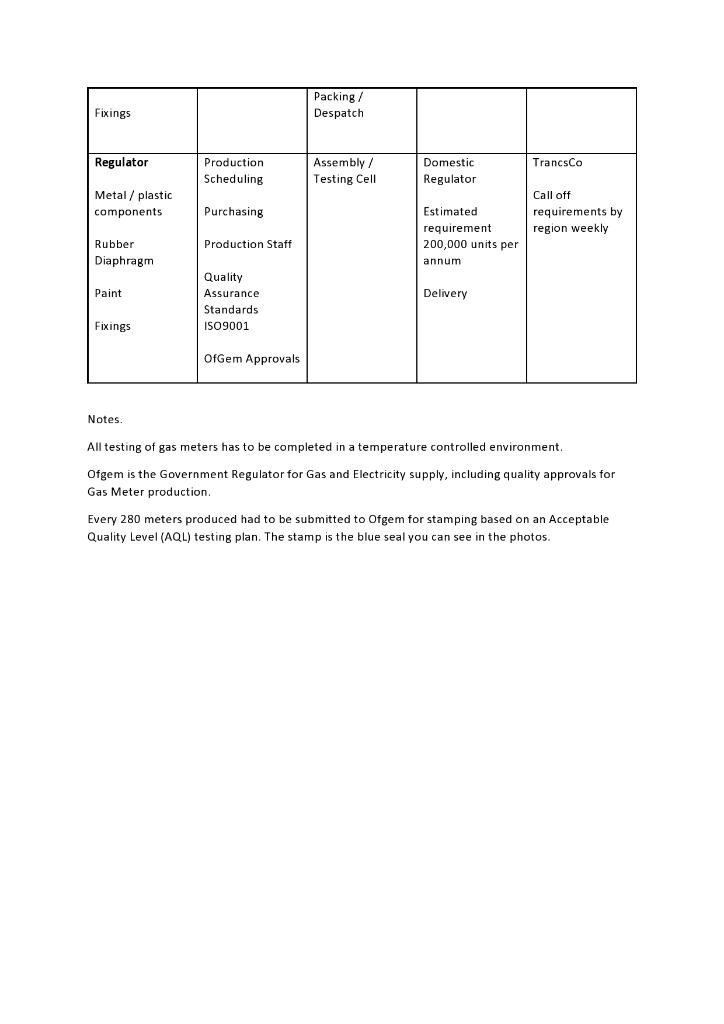

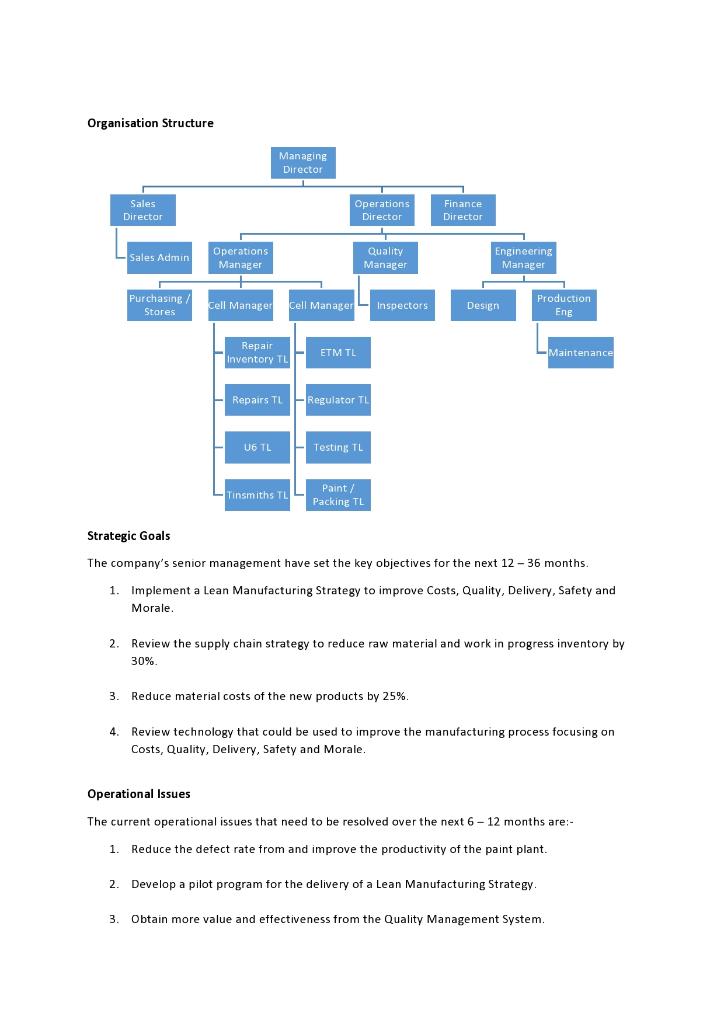

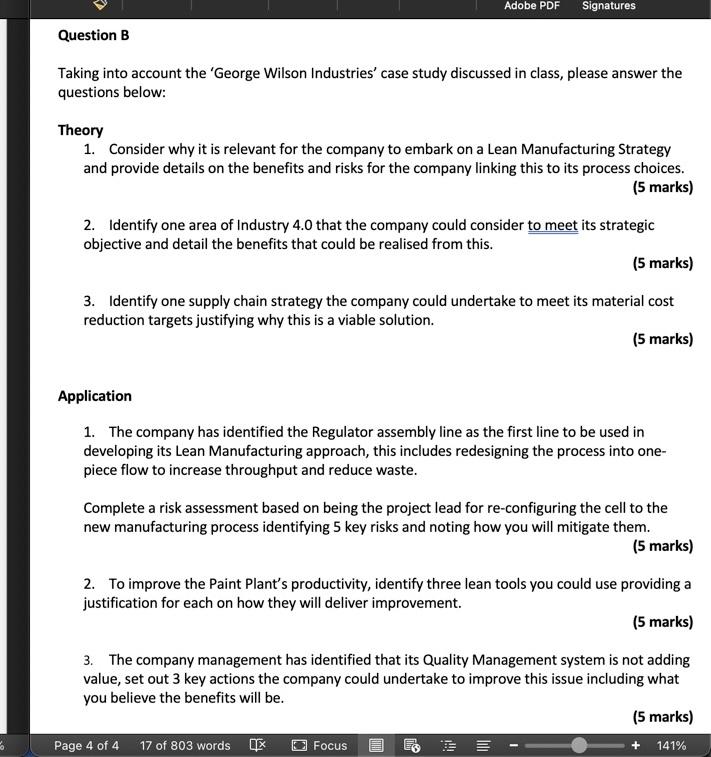

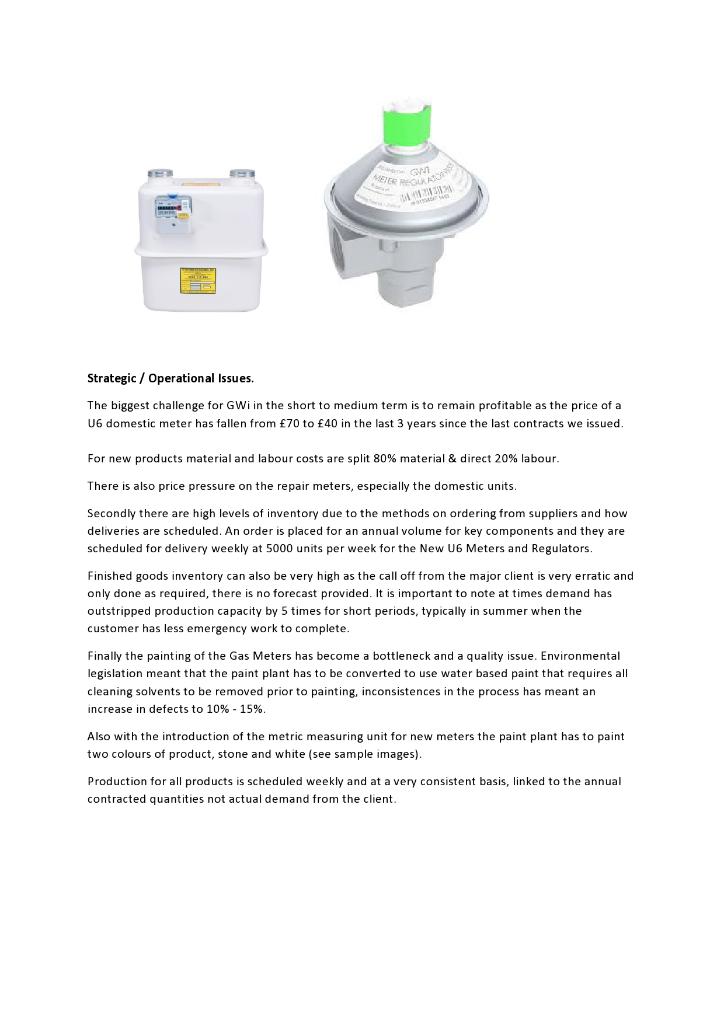

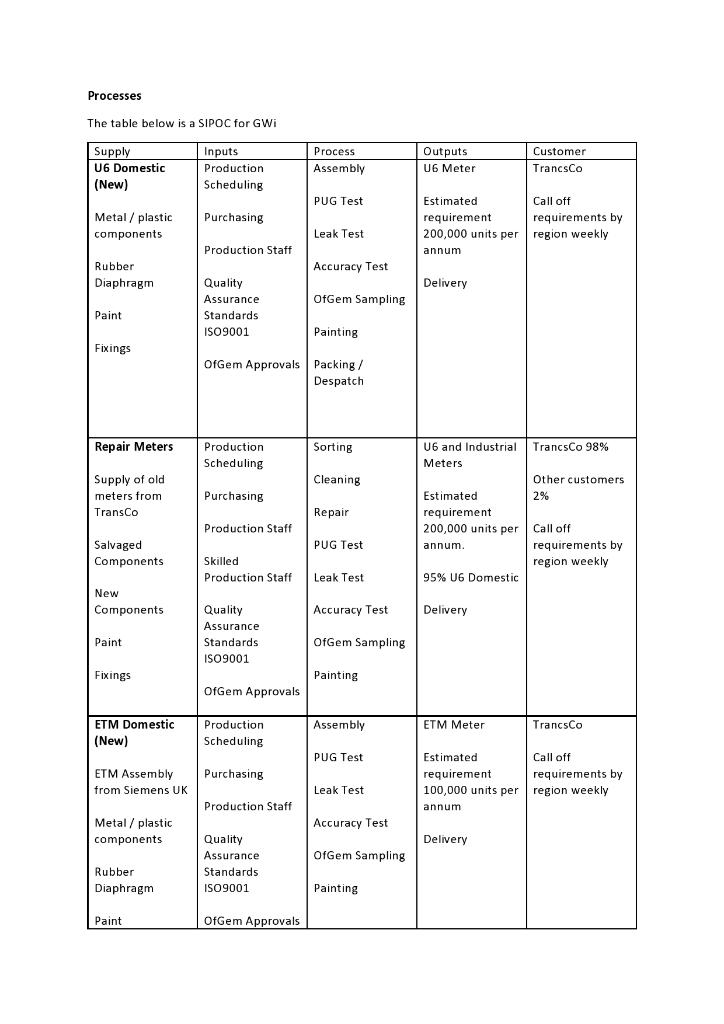

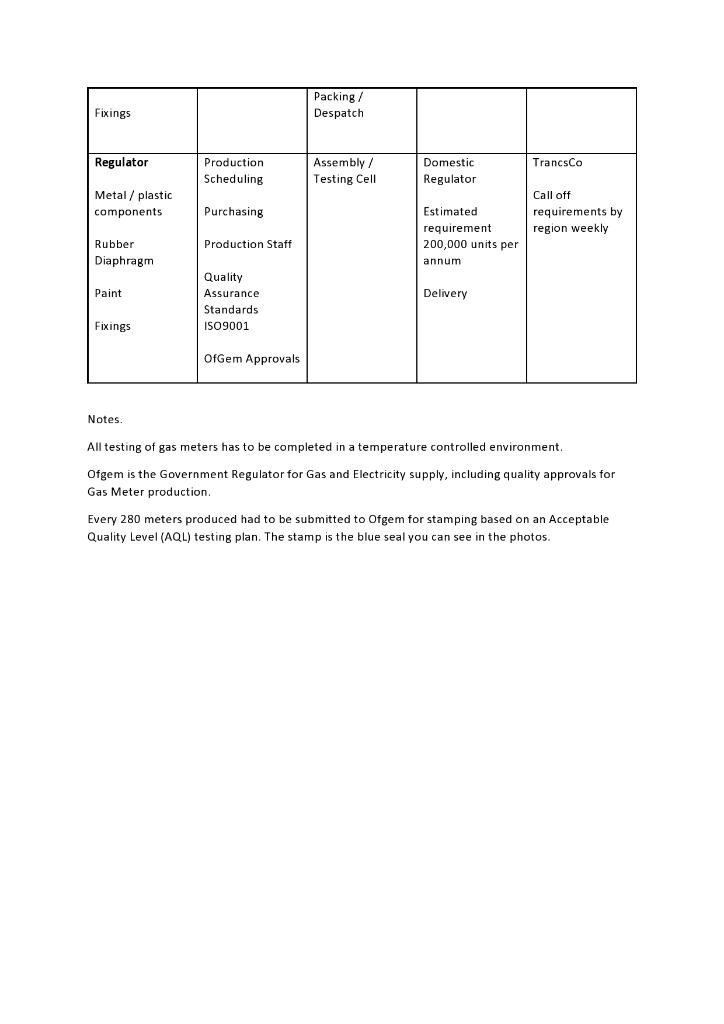

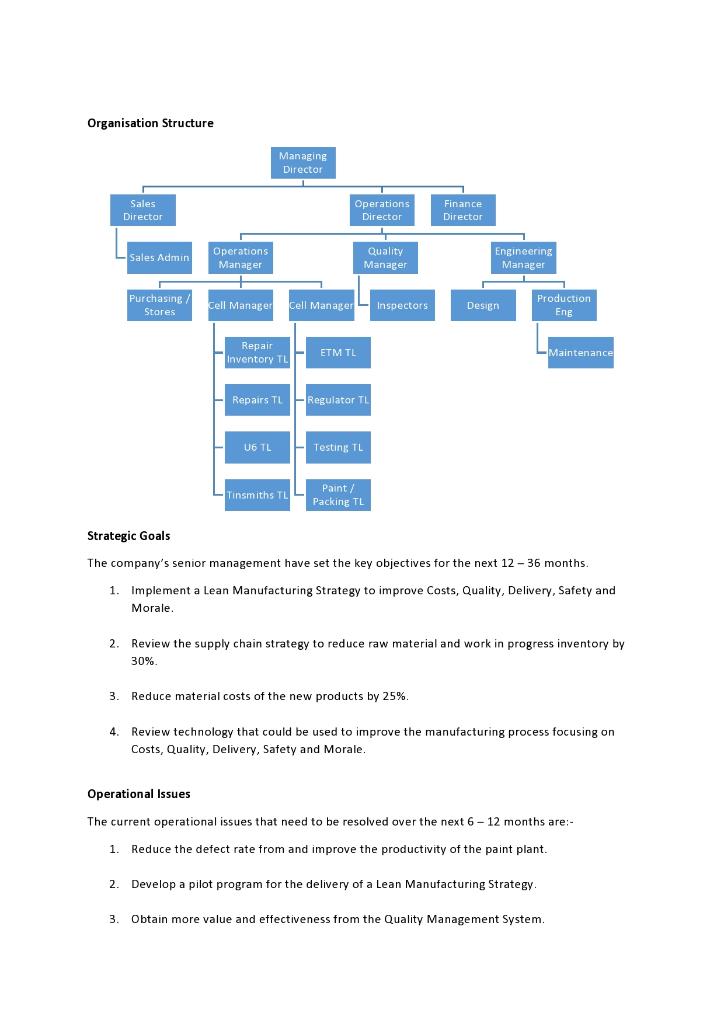

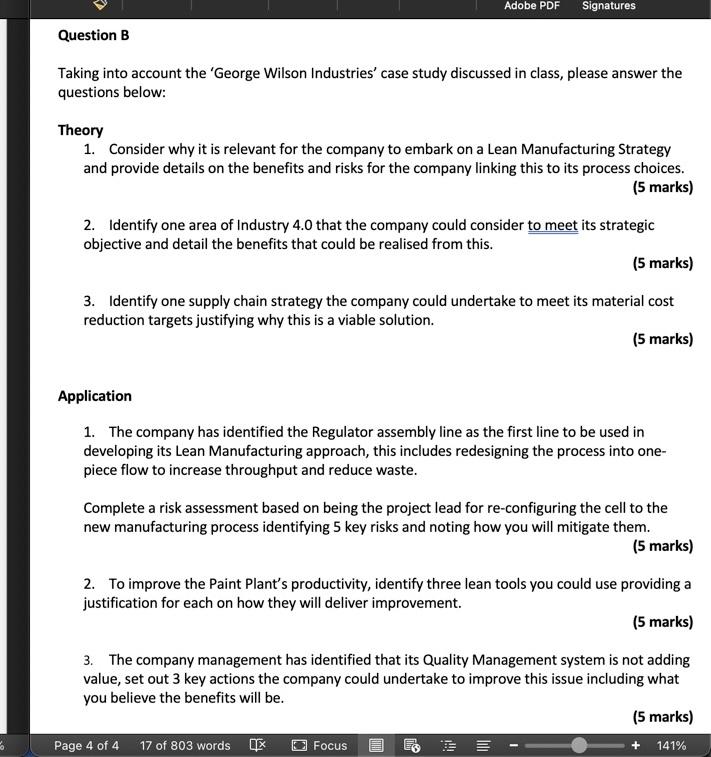

Adobe PDF Signatures Question B Taking into account the 'George Wilson Industries' case study discussed in class, please answer the questions below: Theory 1. Consider why it is relevant for the company to embark on a Lean Manufacturing Strategy and provide details on the benefits and risks for the company linking this to its process choices. (5 marks) 2. Identify one area of Industry 4.0 that the company could consider to meet its strategic objective and detail the benefits that could be realised from this. (5 marks) 3. Identify one supply chain strategy the company could undertake to meet its material cost reduction targets justifying why this is a viable solution. (5 marks) Application 1. The company has identified the Regulator assembly line as the first line to be used in developing its Lean Manufacturing approach, this includes redesigning the process into one- piece flow to increase throughput and reduce waste. Complete a risk assessment based on being the project lead for re-configuring the cell to the new manufacturing process identifying 5 key risks and noting how you will mitigate them. (5 marks) 2. To improve the Paint Plant's productivity, identify three lean tools you could use providing a justification for each on how they will deliver improvement. (5 marks) 3. The company management has identified that its Quality Management system is not adding value, set out 3 key actions the company could undertake to improve this issue including what you believe the benefits will be. (5 marks) Page 4 of 4 17 of 803 words x Focus 141% Background. Steeped in history and empowered by the latest technology, George Wilson Industries and its parent company Metrix represent a union of expertise and ability. The companies have enormous strength and depth, not just from each other but as part of the Adaptor Group they have access to a worldwide pool of engineering Resources. GWi was founded by George Wilson in 1878 and our experience in the gas industry is extremely comprehensive. Our UK manufacturing centre is based in Coventry, promoting growth of the UK economy and creating local jobs. Its operations are centred on production of domestic pressure regulators and innovative diaphragm gas meters, using state of the art electronics and communication technologies for smart meters. Through our environmental policies and refurbishment services for all makes of meter, we offer real benefits to reduce the carbon footprint for our customers and the re-utilisation of stranded assets. GWi is a BS EN 18001 (Health and Safety), BS EN ISO 9001 (Quality), BS EN ISO 14001 (Environmental) and BS EN ISO 27001 (Information Security) accredited company - visit our download page for our company and products certification. (From website www.gwi-Itd.co.uk) The Gars market in the UK still has only one major supplier and infrastructure management business, British Gas for consumer supply and TransCo for infrastructure management. TransCo had as dual sourcing policy for most of its key requirements including Gas Meters and Regulators. GWI make and repair domestic Gas Meters (U6 & U6ETM), repair low volumes of Industrial Meters and make Regulators (SR100) for domestic supply. Examples of these products are below. 95 ESE 4 Wood Baple Electronic Token Meter 0800 111 999 ETM means an Electronic Token Meter, this is a prepay system. F Strategic / Operational Issues, The biggest challenge for GWi in the short to medium term is to remain profitable as the price of a U6 domestic meter has fallen from 70 to 40 in the last years since the last contracts we issued. For new products material and labour costs are split 80% material & direct 20% labour. There is also price pressure on the repair meters, especially the domestic units. Secondly there are high levels of inventory due to the methods on ordering from suppliers and how deliveries are scheduled. An order is placed for an annual volume for key components and they are scheduled for delivery weekly at 5000 units per week for the New U6 Meters and Regulators. Finished goods inventory can also be very high as the call off from the major client is very erratic and only done as required, there is no forecast provided. It is important to note at times demand has outstripped production capacity by 5 times for short periods, typically in summer when the customer has less emergency work to complete. Finally the painting of the Gas Meters has become a bottleneck and a quality issue. Environmental legislation meant that the paint plant has to be converted to use water based paint that requires all cleaning solvents to be removed prior to painting, inconsistences in the process has meant an increase in defects to 10%-15% Also with the introduction of the metric measuring unit for new meters the paint plant has to paint two colours of product, stone and white (see sample images). Production for all products is scheduled weekly and at a very consistent basis, linked to the annual contracted quantities not actual demand from the client. Processes The table below is a SIPOC for GWi Supply U6 Domestic (New) Inputs Production Scheduling Process Assembly Outputs U6 Meter Customer TrancsCo PUG Test Purchasing Metal / plastic components Estimated Call off requirement requirements by 200,000 units per region weekly annum Leak Test Production Staff Rubber Diaphragm Accuracy Test Delivery OfGem Sampling Quality Assurance Standards ISO9001 Paint Painting Fixings OfGem Approvals Packing/ Despatch Repair Meters Production Scheduling Sorting Cleaning Supply of old meters from TransCo Purchasing Repair U6 and Industrial TrancsCo 98% Meters Other customers Estimated 2% requirement 200,000 units per Call off annum requirements by region weekly 95% U6 Domestic Production Staff PUG Test Salvaged Components Skilled Production Staff Leak Test New Components Accuracy Test Delivery Quality Assurance Standards ISO9001 Paint OfGem Sampling Fixings Painting OfGem Approvals Assembly ETM Meter TrancsCo ETM Domestic (New) Production Scheduling PUG Test Purchasing ETM Assembly from Siemens UK Estimated Call off requirement requirements by 100,000 units per region weekly annum Leak Test Production Staff Accuracy Test Metal/ plastic components Delivery Quality Assurance Standards OfGem Sampling Rubber Diaphragm ISO9001 Painting Paint OfGem Approvals Packing/ Fixings Despatch Regulator TrancsCo Production Scheduling Assembly / Testing Cell Domestic Regulator Metal / plastic components Purchasing Call off requirements by region weekly Estimated requirement 200,000 units per annum Production Staff Rubber Diaphragm Paint Delivery Quality Assurance Standards ISO9001 Fixings OfGem Approvals Notes All testing of gas meters has to be completed in a temperature controlled environment. Ofgem is the Government Regulator for Gas and Electricity supply, including quality approvals for Gas Meter production Every 280 meters produced had to be submitted to Ofgem for stamping based on an Acceptable Quality Level (AQL) testing plan. The stamp is the blue seal you can see in the photos. Organisation Structure Managing Director Sales Director Operations Finance Director Director Sales Admin Operations Manager Quality Manager Engineering Manager Purchasing / Stores Cell Manager Cell Manager Cell Manager Inspectors Design Production Eng Repair Inventory TL ETM TL Maintenance Repairs TL Regulator TL U6 TL Testing TL Tinsmiths TL Paint / Packing TL Strategic Goals The company's senior management have set the key objectives for the next 12-36 months. 1. Implement a Lean Manufacturing Strategy to improve Costs, Quality, Delivery, Safety and Morale. 2. Review the supply chain strategy to reduce raw material and work in progress inventory by 30% 3. Reduce material costs of the new products by 25%. 4. Review technology that could be used to improve the manufacturing process focusing on Costs, Quality, Delivery, Safety and Morale. Operational Issues The current operational issues that need to be resolved over the next 6 - 12 months are:- 1. Reduce the defect rate from and improve the productivity of the paint plant. 2. Develop a pilot program for the delivery of a Lean Manufacturing Strategy. 3. Obtain more value and effectiveness from the Quality Management System

THE CASE STUDY CONTINUES IN THE NEXT QUESTION

THE CASE STUDY CONTINUES IN THE NEXT QUESTION