Question: The coursework will be on modelling the interactions between a nanosecond (ns) laser source and metals. Thus, the processing mechanism in such laser- material

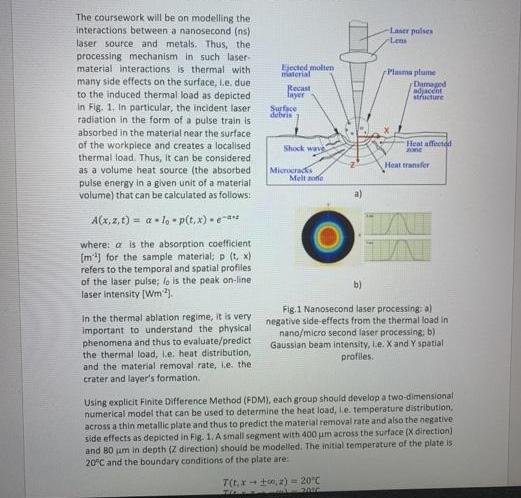

The coursework will be on modelling the interactions between a nanosecond (ns) laser source and metals. Thus, the processing mechanism in such laser- material interactions is thermal with many side effects on the surface, L.e. due to the induced thermal load as depicted. in Fig. 1. In particular, the incident laser radiation in the form of a pulse train is absorbed in the material near the surface of the workpiece and creates a localised thermal load. Thus, it can be considered as a volume heat source (the absorbed pulse energy in a given unit of a material volume) that can be calculated as follows: A(x,z,t) a lop(t, x) - e where: a is the absorption coefficient i [m] for the sample material; p (t, x) refers to the temporal and spatial profiles of the laser pulse; lo is the peak on-line laser intensity [Wm2]. In the thermal ablation regime, it is very important to understand the physical phenomena and thus to evaluate/predict the thermal load, i.e. heat distribution, and the material removal rate, i.e. the i crater and layer's formation. Ejected molten. material Recast layer THE Surface debris Shock wave Microcracks Melt offe Laser pulses Lens T(t.x+2) = 20C 2016 Plasma plame Damaged adjacent structure Heat affected zone Heat transfer Fig.1 Nanosecond laser processing: a) negative side-effects from the thermal load in nano/micro second laser processing; b) Gaussian beam intensity, L.e. X and Y spatial profiles. Using explicit Finite Difference Method (FDM), each group should develop a two-dimensional numerical model that can be used to determine the heat load, L.e. temperature distribution, across a thin metallic plate and thus to predict the material removal rate and also the negative i side effects as depicted in Fig. 1. A small segment with 400 um across the surface (X direction) and 80 um in depth (Z direction) should be modelled. The initial temperature of the plate is 20C and the boundary conditions of the plate are:

Step by Step Solution

3.54 Rating (151 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts