Question: The current maintenance policy being adopted for a complex transfer machine in continuous operation is that inspections are made once every 4 weeks. Any potential

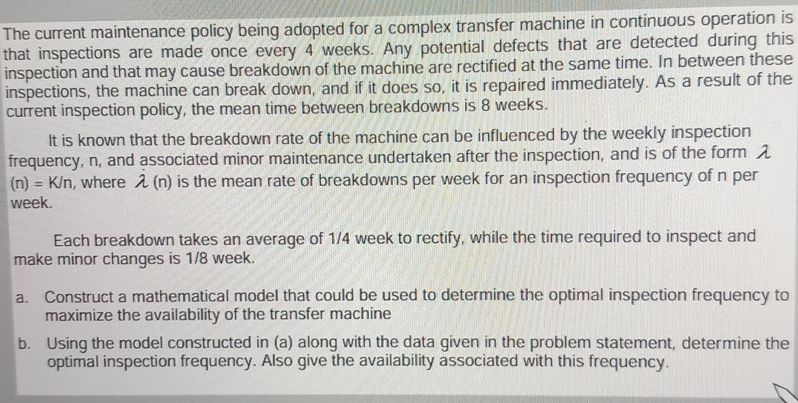

The current maintenance policy being adopted for a complex transfer machine in continuous operation is that inspections are made once every weeks. Any potential defects that are detected during this inspection and that may cause breakdown of the machine are rectified at the same time. In between these inspections, the machine can break down, and if it does so it is repaired immediately. As a result of the current inspection policy, the mean time between breakdowns is weeks.

It is known that the breakdown rate of the machine can be influenced by the weekly inspection frequency, and associated minor maintenance undertaken after the inspection, and is of the form where is the mean rate of breakdowns per week for an inspection frequency of per week.

Each breakdown takes an average of week to rectify, while the time required to inspect and make minor changes is week.

a Construct a mathematical model that could be used to determine the optimal inspection frequency to maximize the availability of the transfer machine

b Using the model constructed in a along with the data given in the problem statement, determine the optimal inspection frequency. Also give the availability associated with this frequency.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock