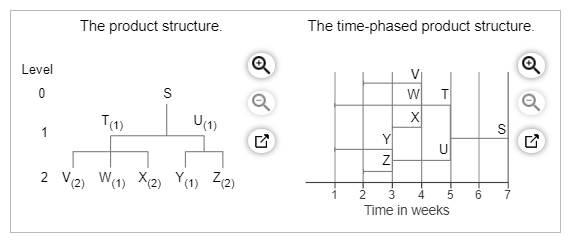

Question: The demand for subassembly S is 80 units in week 7. Each unit of S requires 1 unit of T and 1 unit of U.

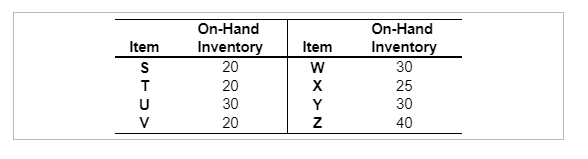

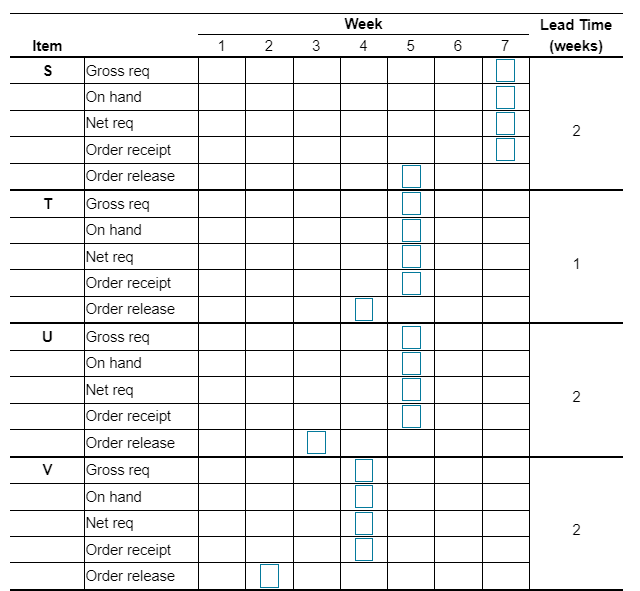

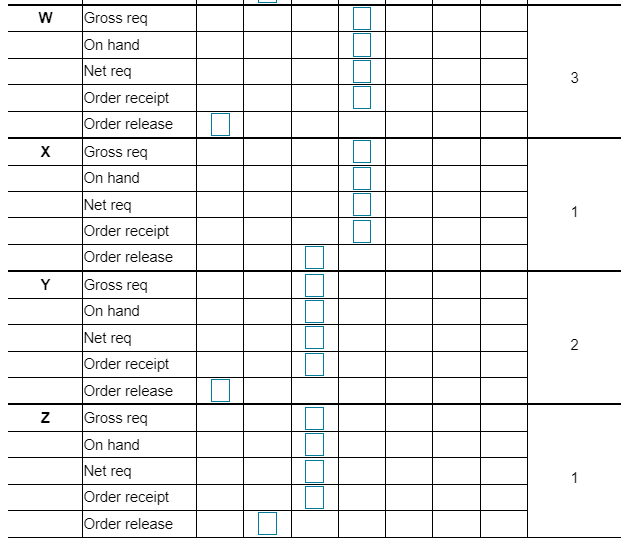

The demand for subassembly S is 80 units in week 7. Each unit of S requires 1 unit of T and 1 unit of U. Each unit of T requires 2 units of V, 1-unit of W, and 2 units of X. Finally, each unit of U requires 1 unit of Y and 2 units of Z. One firm manufactures all items. It takes 2 weeks to make S, 1 week to make T, 2 weeks to make U, 2 weeks to make V, 3 weeks to make W, 1 week to make X, 2 weeks to make Y, and 1 week to make Z.

Construct net material requirements plan using on-hand inventory (enter your responses as whole numbers).

The Whole Question ^

The Whole Question ^

I'm really lost and needing some guidance.

The product structure. The time-phased product structure. Q V Level 0 S Q 19 WT x T(1) U (1) 1 Y LY C 2 V2) W(1) X(2) Y(1) Z(2) 1 6 2 3 4 5 Time in weeks Item Item S T On-Hand Inventory 20 20 30 20 On-Hand Inventory 30 25 30 40 ED> 3X>N Y Z Week 4 Lead Time (weeks) Item 1 2 3 5 6 7 s 2 T Gross req On hand Net req Order receipt Order release Gross req On hand Net req Order receipt Order release Gross req On hand 1 U Net req 2 N V Order receipt Order release Gross req On hand Net req Order receipt Order release 2 W 3 1 Gross req On hand Net req Order receipt Order release Gross req On hand Net req Order receipt Order release Gross req On hand Net req Order receipt Order release Gross req On hand Net req Order receipt Order release Y 2 z 1 The demand for subassembly S is 80 units in week 7. Each unit of Srequires 1 unit of T and 1 unit of U. Each unit of T requires 2 units of V, 1 unit of W, and 2 units of X. Finally, each unit of U requires 1 unit of Y and 2 units of Z. One firm manufactures all items. It takes 2 weeks to make S, 1 week to make T, 2 weeks to make U, 2 weeks to make V, 3 weeks to make W, 1 week to make X, 2 weeks to make Y, and 1 week to make Z. Click the icon to view the product structure and the time-phased product structure. 3 Click the icon to view the on-hand inventory. Construct a net material requirements plan using on-hand inventory (enter your responses as whole numbers)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock