Question: The first continuous chemical manufacturing process was developed by the Belgian chemist Ernest Solvay during the 1860s. The Solvay process or ammonia-soda process is the

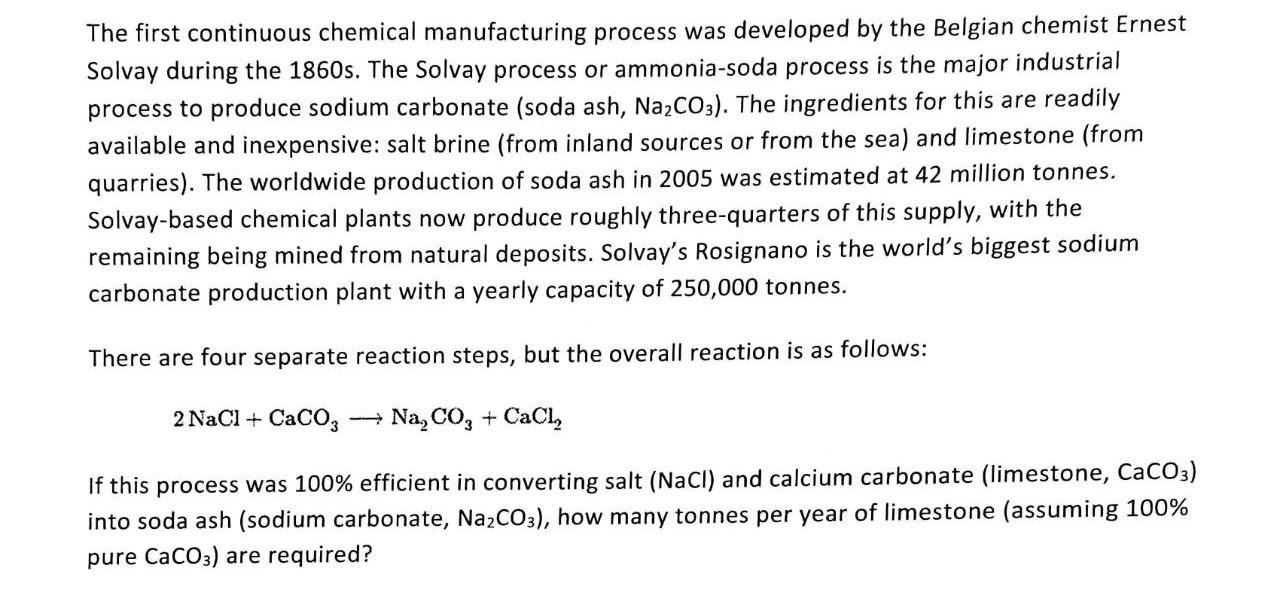

The first continuous chemical manufacturing process was developed by the Belgian chemist Ernest Solvay during the 1860s. The Solvay process or ammonia-soda process is the major industrial process to produce sodium carbonate (soda ash, Na2CO3 ). The ingredients for this are readily available and inexpensive: salt brine (from inland sources or from the sea) and limestone (from quarries). The worldwide production of soda ash in 2005 was estimated at 42 million tonnes. Solvay-based chemical plants now produce roughly three-quarters of this supply, with the remaining being mined from natural deposits. Solvay's Rosignano is the world's biggest sodium carbonate production plant with a yearly capacity of 250,000 tonnes. There are four separate reaction steps, but the overall reaction is as follows: 2NaCl+CaCO3Na2CO3+CaCl2 If this process was 100% efficient in converting salt (NaCl) and calcium carbonate (limestone, CaCO3 ) into soda ash (sodium carbonate, Na2CO3 ), how many tonnes per year of limestone (assuming 100% pure CaCO3 ) are required

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts