Question: The fixed overhead is distributed using activity-based costing principles. For example, at current production levels, the forming machine spends 100 hours on model S shelves

The fixed overhead is distributed using activity-based costing principles. For example, at current production levels, the forming machine spends 100 hours on model S shelves and 700 hours on model LX shelves. The forming machine is used 800 hours of the month, of which 12.5% of the time is spent on model S shelves and 87.5% is spent on model LX shelves. The $95,000 of fixed overhead in the forming department is distributed as $11,875 (= 95,000 0.125) to model S shelves and $83,125 (= 95,000 0.875) to model LX shelves. The fixed overhead per unit of output is allocated as $29.69 (= 11,875/400) for model S and $59.38 (= 83,125/400) for model LX. In the calculation of the standard overhead cost, the fixed and variable costs are added together, so that the overhead cost for the forming department allocated to a model S shelf is $149.69 (= 29.69 + 120, shown in cell G20 rounded up to $150). Similarly, the overhead cost for the forming department allocated to a model LX shelf is $229.38 (= 59.38 + 170, shown in cell H20 rounded down to $229).

- What are the best production plan for Shelby Shelving? What is the best profit the firm can achieve?

- Who will you support between the engineer and the controller? Give a short verbal argument on why you do so.

- Suppose Shelby wants to invest on their three departments capacity. Do some sensitivity analysis and answer the following questions.

- Does all departments capacity need to increase? Give the reason to support your claim.

- In general, which departments capacity should be considered the first to increase? Why?

- Suppose there are some additional restrictions on the capacity expanding investment.

- Shelby plans to borrow at most $1500 from the bank atannual rate of 12% for one month, to implement any possible capacity expanding.

- It costs $150 to increase every one hour of capacity in forming department, and $100 for increasing every one hour of stamping capacity.

- In assembly department, the capacity for Model S and Model LX can be easily converted, without any cost, between each other for any amount smaller than 20 units. But it costs $300 for any conversion beyond the first 20 units and for any unit of new capacity expanding.

Please answer the following questions.

- If Shelby can only change one departments capacity, which department should be selected? And why?

- If Shelby can change multiple departments capacity, could you propose a best investment plan? What is it?

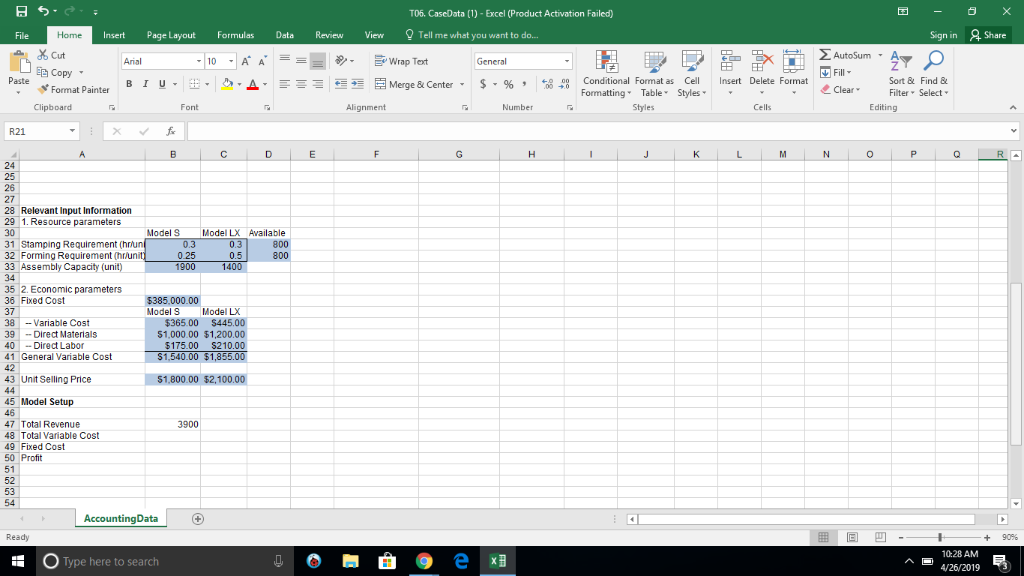

. TO6. CaseData (1)-Excel (Product Activation Failed) Insert Page LayoutFormulasData Review View T Home Tell me what you want to do... Sign in Share s Cut AutoSum . A FillSort&t Find& Sort &Find & -Merge & Center . $ . % , 1.000 Conditional Format as Cell insert Delete Format tyra B 1 u E- 2-A. Format Painter Formatting Table Styles Filter Select Font Alignment Cells Editing R21 28 Relevant Input Information 29 1. Resource parameters Model S Model LX Available 31 Stamping Requirement 32 Forming Requirement (hr/unit 33 Assembly Capacity (unit) 1900 1400 35 2. Economic parameters 36 Fixed Cost $385,000 Model S Model LX $365.00 $445.00 $1,000.00 $1,200.00 $175.00 $210.00 38Variable Cost 39Direct Materials 40Direct Labor 41 General Variable Cost $1,540.00 $1,855.0 $1,800.00 $2,100.00 43 Unit Selling Price 45 Model Setup 47 Total Revenue 48 Total Variable Cost 49 Fixed Cost 50 Profit AccountingData Ready +90% 10:28 AM A/26/2019 Type here to search . TO6. CaseData (1)-Excel (Product Activation Failed) Insert Page LayoutFormulasData Review View T Home Tell me what you want to do... Sign in Share s Cut AutoSum . A FillSort&t Find& Sort &Find & -Merge & Center . $ . % , 1.000 Conditional Format as Cell insert Delete Format tyra B 1 u E- 2-A. Format Painter Formatting Table Styles Filter Select Font Alignment Cells Editing R21 28 Relevant Input Information 29 1. Resource parameters Model S Model LX Available 31 Stamping Requirement 32 Forming Requirement (hr/unit 33 Assembly Capacity (unit) 1900 1400 35 2. Economic parameters 36 Fixed Cost $385,000 Model S Model LX $365.00 $445.00 $1,000.00 $1,200.00 $175.00 $210.00 38Variable Cost 39Direct Materials 40Direct Labor 41 General Variable Cost $1,540.00 $1,855.0 $1,800.00 $2,100.00 43 Unit Selling Price 45 Model Setup 47 Total Revenue 48 Total Variable Cost 49 Fixed Cost 50 Profit AccountingData Ready +90% 10:28 AM A/26/2019 Type here to search

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts