Question: (The following problem context is taken from the Custom Textbook of Purdue University for the course MGMT 36100 - Operations Management.) Rockness Recycling refurbishes rundown

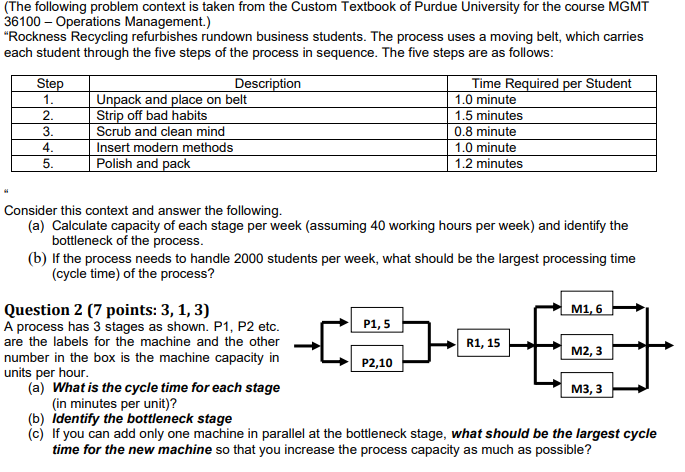

(The following problem context is taken from the Custom Textbook of Purdue University for the course MGMT 36100 - Operations Management.) "Rockness Recycling refurbishes rundown business students. The process uses a moving belt, which carries each student through the five steps of the process in sequence. The five steps are as follows: Consider this context and answer the following. (a) Calculate capacity of each stage per week (assuming 40 working hours per week) and identify the bottleneck of the process. (b) If the process needs to handle 2000 students per week, what should be the largest processing time (cycle time) of the process? Question 2 (7 points: 3,1,3) A process has 3 stages as shown. P1, P2 etc. are the labels for the machine and the other number in the box is the machine capacity in units per hour. (a) What is the cycle time for each stage (in minutes per unit)? (b) Identify the bottleneck stage (c) If you can add only one machine in parallel at the bottleneck stage, what should be the largest cycle time for the new machine so that you increase the process capacity as much as possible

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts