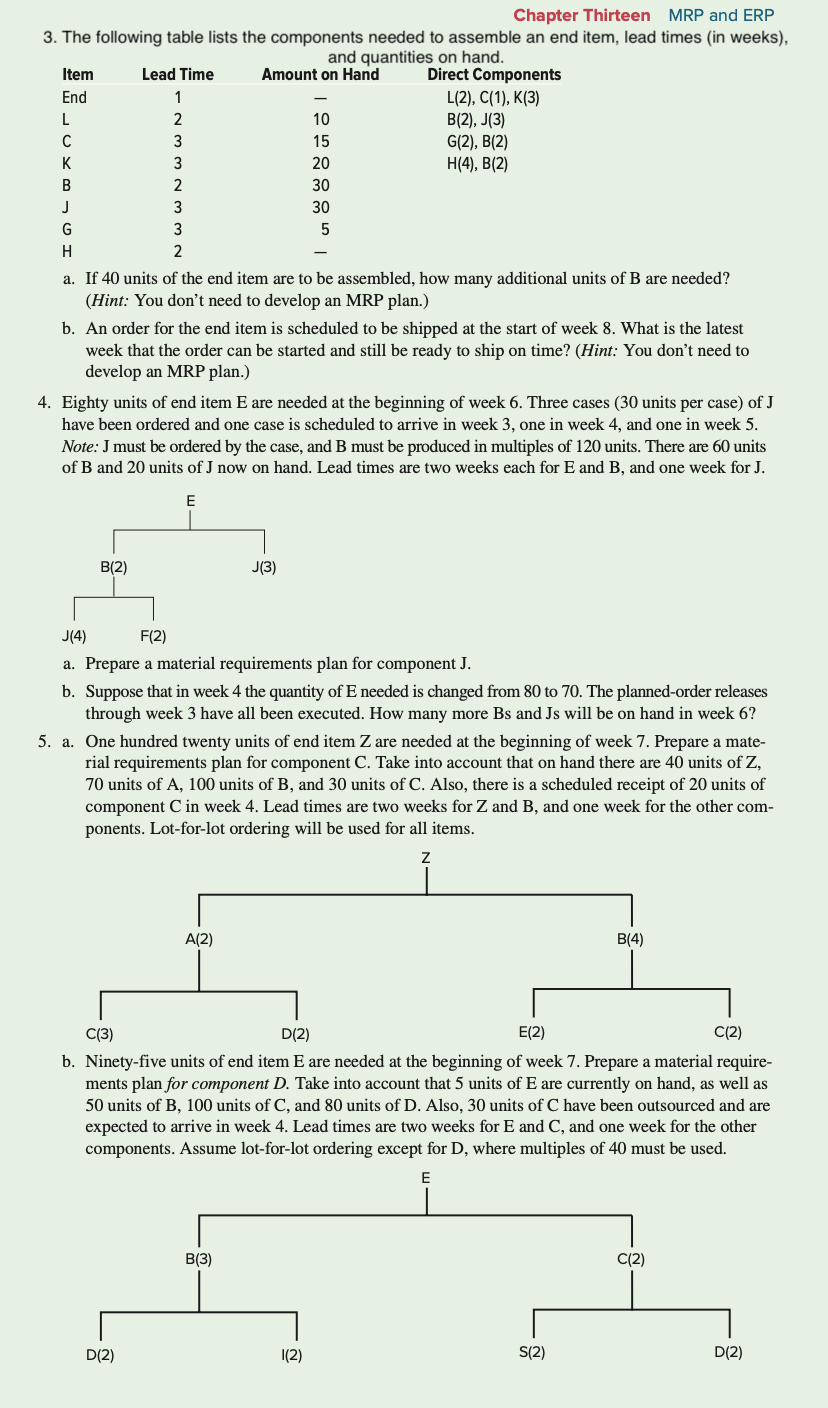

Question: The following table lists the components needed to assemble an end item, lead times ( in weeks ) , and quantities on hand.Chapter Thirteen MRP

The following table lists the components needed to assemble an end item, lead times in weeks and quantities on hand.Chapter Thirteen MRP and ERP

The following table lists the components needed to assemble an end item, lead times in weeks

and quantities on hand.

a If units of the end item are to be assembled, how many additional units of are needed?

Hint: You don't need to develop an MRP plan.

b An order for the end item is scheduled to be shipped at the start of week What is the latest

week that the order can be started and still be ready to ship on time? Hint: You don't need to

develop an MRP plan.

Eighty units of end item are needed at the beginning of week Three cases units per case of

have been ordered and one case is scheduled to arrive in week one in week and one in week

Note: must be ordered by the case, and must be produced in multiples of units. There are units

of B and units of now on hand. Lead times are two weeks each for E and B and one week for J

a Prepare a material requirements plan for component

b Suppose that in week the quantity of needed is changed from to The plannedorder releases

through week have all been executed. How many more Bs and Js will be on hand in week

a One hundred twenty units of end item are needed at the beginning of week Prepare a mate

rial requirements plan for component Take into account that on hand there are units of

units of A units of B and units of C Also, there is a scheduled receipt of units of

component in week Lead times are two weeks for and and one week for the other com

ponents. Lotforlot ordering will be used for all items.

b Ninetyfive units of end item E are needed at the beginning of week Prepare a material require

ments plan for component Take into account that units of are currently on hand, as well as

units of B units of C and units of D Also, units of C have been outsourced and are

expected to arrive in week Lead times are two weeks for E and C and one week for the other

components. Assume lotforlot ordering except for where multiples of must be used.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock