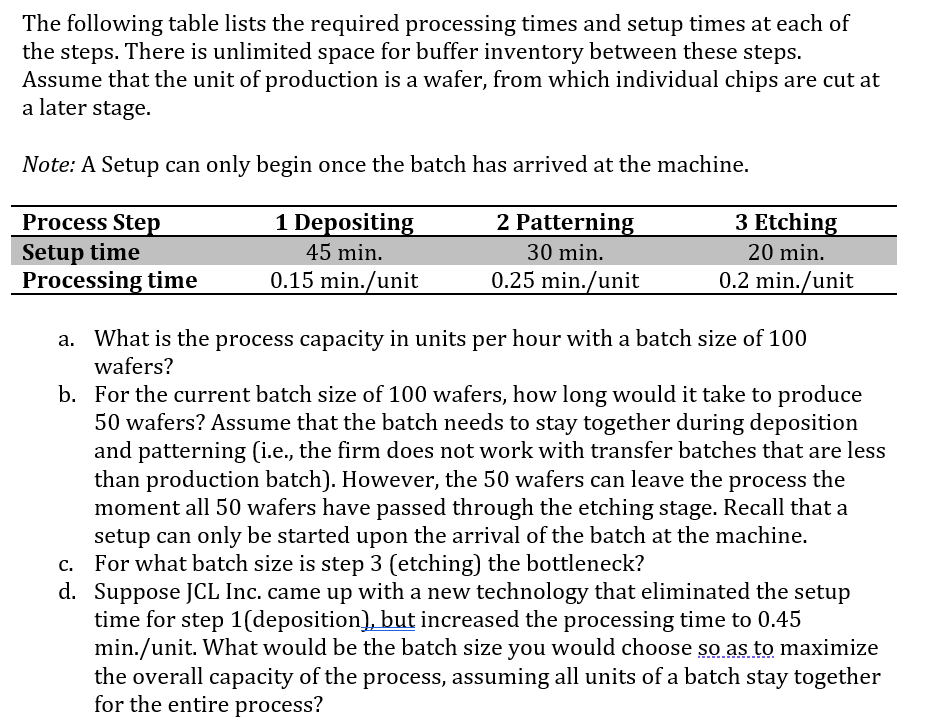

Question: The following table lists the required processing times and setup times at each of the steps. There is unlimited space for buffer inventory between these

The following table lists the required processing times and setup times at each of the steps. There is unlimited space for buffer inventory between these steps. Assume that the unit of production is a wafer, from which individual chips are cut at a later stage. Note: A Setup can only begin once the batch has arrived at the machine. a. What is the process capacity in units per hour with a batch size of 100 wafers? b. For the current batch size of 100 wafers, how long would it take to produce 50 wafers? Assume that the batch needs to stay together during deposition and patterning (i.e., the firm does not work with transfer batches that are less than production batch). However, the 50 wafers can leave the process the moment all 50 wafers have passed through the etching stage. Recall that a setup can only be started upon the arrival of the batch at the machine. c. For what batch size is step 3 (etching) the bottleneck? d. Suppose JCL Inc. came up with a new technology that eliminated the setup time for step 1(deposition), but increased the processing time to 0.45 min./unit. What would be the batch size you would choose so as to maximize the overall capacity of the process, assuming all units of a batch stay together for the entire process

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts