Question: the most optimum values you can get. 3 . Estimate the duration of this mission. 4 . Design the diverging part of the nozzle. Here

the most optimum values you can get.

Estimate the duration of this mission.

Design the diverging part of the nozzle. Here you can ignore the effect of heat transfer on your nozzle design procedure. Technical drawings for the nozzle are expected for this part.

Assuming no change in the working conditions of the turbomachinery components, qualitatively describe what happens to the exit flow conditions when the rocket is taken to some atmosphere with higher or lower pressure.

Estimate the length of the main combustion chamber.

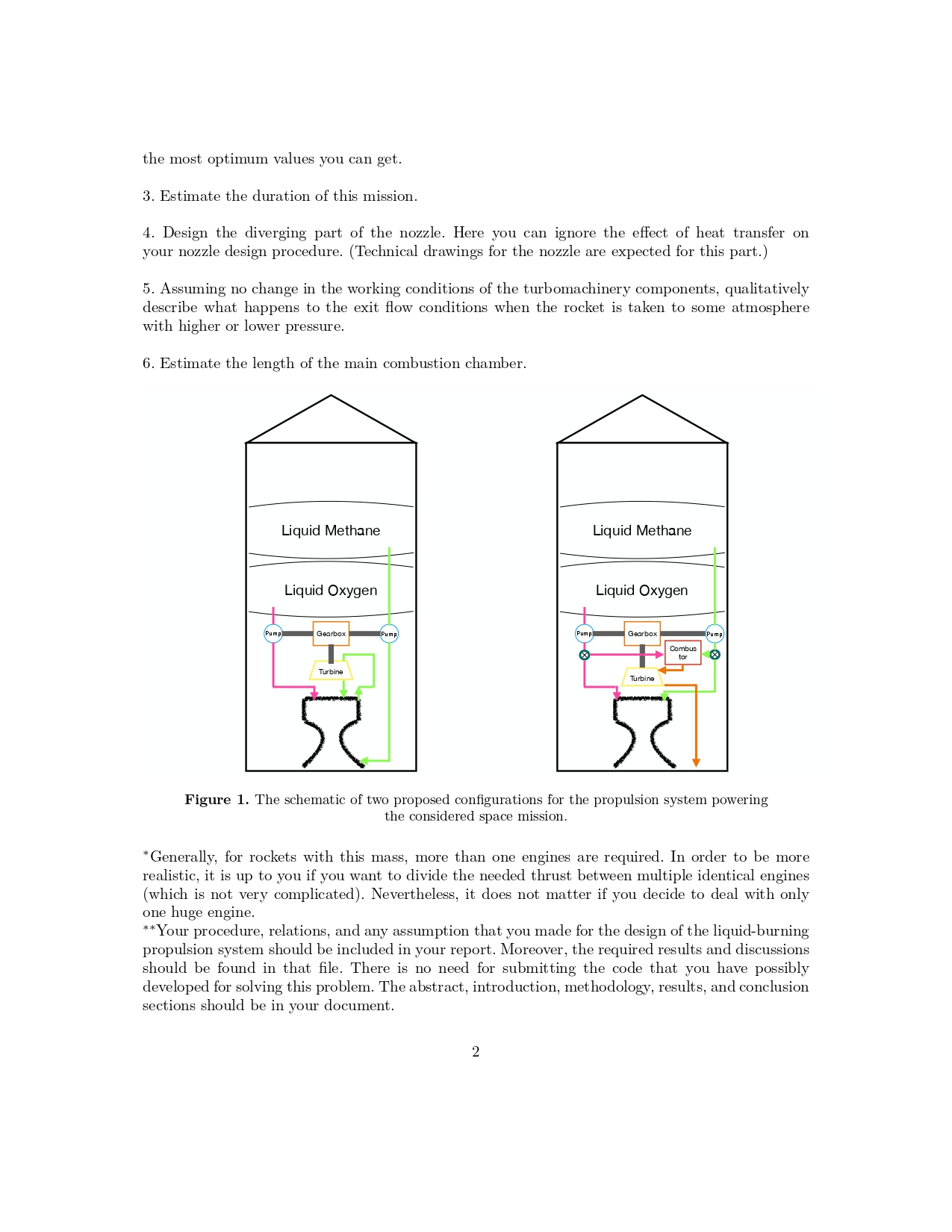

Figure The schematic of two proposed configurations for the propulsion system powering the considered space mission.

Generally, for rockets with this mass, more than one engines are required. In order to be more realistic, it is up to you if you want to divide the needed thrust between multiple identical engines which is not very complicated Nevertheless, it does not matter if you decide to deal with only one huge engine.

Your procedure, relations, and any assumption that you made for the design of the liquidburning propulsion system should be included in your report. Moreover, the required results and discussions should be found in that file. There is no need for submitting the code that you have possibly developed for solving this problem. The abstract introduction, methodology, results, and conclusion sections should be in your document. Returning from Mars: The Preliminary Design of a LiquidPropellant Rocket Engine

Aerospace Propulsion: Project

Introduction

In this project, we are going to design the thrust chamber of a liquidburning chemical rocket which will be considered for returning astronauts to an imaginary multinational space station located in the Martian geostationary orbit at the altitude of km from the surface of Mars. Assume that the astronauts can handle linear accelerations up to times of the gravitational acceleration on the surface of Mars. Meanwhile, consider kg for the dry mass of the rocket. As the spaceship needs to be refueled on Mars, methane and oxygen are selected as the fuel and oxidizer of the rocket, respectively, due to the feasibility of their production on Mars. You can assume the design point of the nozzle to be considered on the surface of Mars. In addition, assume that the maximum pressure ratio for the fuel and oxidizer pumps is and they work at constant rates during the mission. Moreover, you can ignore the drag forces exerted on the spacecraft. On the other hand, you need to consider a reasonable model for the gravitational force and ambient pressure as functions of altitude from the Mars surface. For simplicity, you can assume a fixed ambient pressure throughout the mission.

Two different configurations which are illustrated in Fig. are proposed for the propulsion system. In one, the fuel pump circulates the fuel flow around the nozzle so that it gets heated, and after being expanded in an axial turbine, it is injected into the main combustion chamber, and the power of the turbine is transmitted to power the fuel and oxidizer pumps via a gearbox. In the other configuration, some ratio of the fuel and oxidizer flows are guided to an auxiliary combustion chamber to get reacted with the stoichiometric proportions and then power the axial turbine. You may assume that in both designs, the pressure loss for the fuel and oxidizer lines are equal to of the total pressure before reaching the main combustion chamber. In this project, you are allowed to choose either of these two configurations, and design your propulsion system based on your choice. You may need to make some reasonable assumptions regarding the performance characteristics of each component such as turbine, combustion chamber, etc.

Simulation and Analysis

What should be the fuel to oxidizer ratio in the main combustion chamber to get the maximum specific impulse? Estimate the exiting gas velocity and the specific impulse of the rocket at each altitude.

What volume and mass would be required for the fuel and oxidizer reservoirs? Try to obtain

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock