Question: the problem is dealing with Re-Order points 3. Given the following inventory system: average weekly ( 7 days a week) demand is 1000 units with

the problem is dealing with Re-Order points

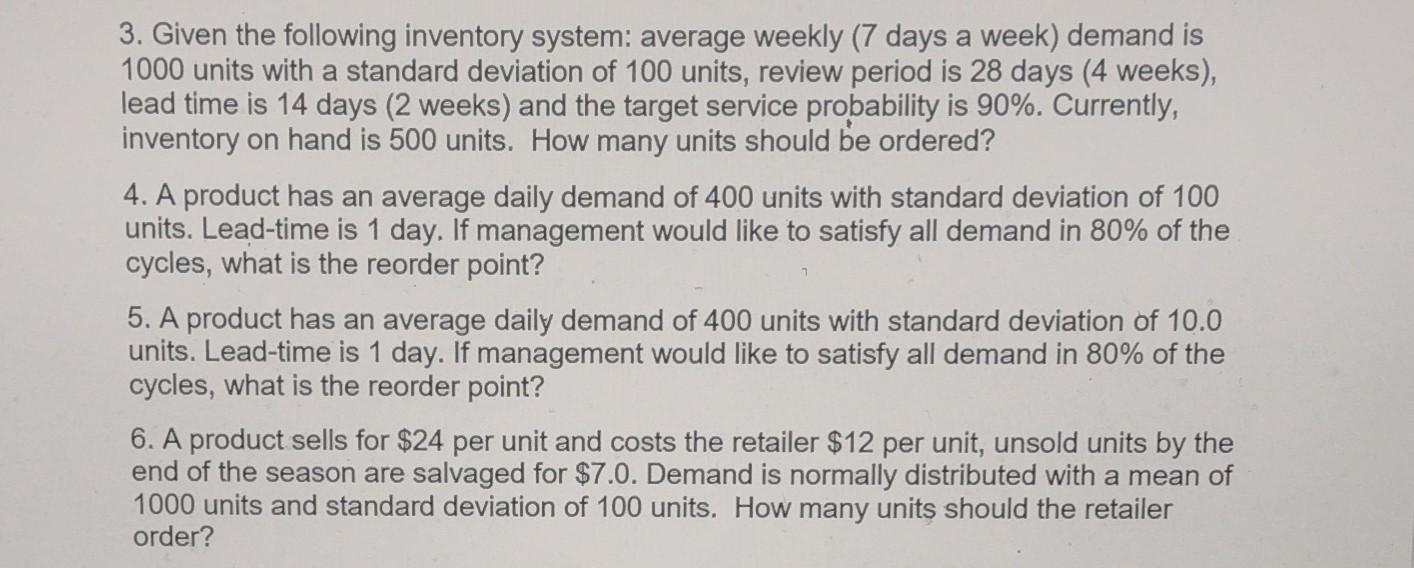

3. Given the following inventory system: average weekly ( 7 days a week) demand is 1000 units with a standard deviation of 100 units, review period is 28 days (4 weeks), lead time is 14 days ( 2 weeks) and the target service probability is 90%. Currently, inventory on hand is 500 units. How many units should be ordered? 4. A product has an average daily demand of 400 units with standard deviation of 100 units. Lead-time is 1 day. If management would like to satisfy all demand in 80% of the cycles, what is the reorder point? 5. A product has an average daily demand of 400 units with standard deviation of 10.0 units. Lead-time is 1 day. If management would like to satisfy all demand in 80% of the cycles, what is the reorder point? 6. A product sells for $24 per unit and costs the retailer $12 per unit, unsold units by the end of the season are salvaged for $7.0. Demand is normally distributed with a mean of 1000 units and standard deviation of 100 units. How many units should the retailer order

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts