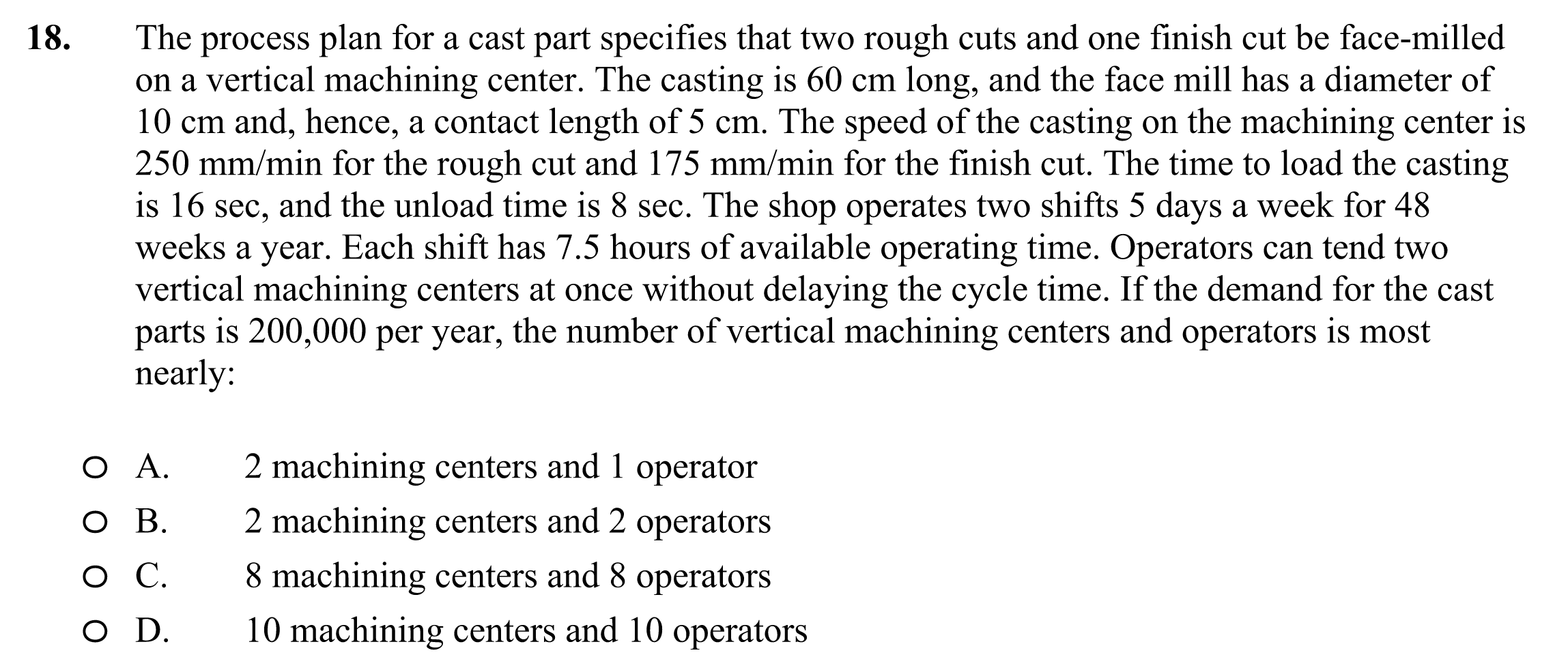

Question: The process plan for a cast part specifies that two rough cuts and one finish cut be face - milled on a vertical machining center.

The process plan for a cast part specifies that two rough cuts and one finish cut be facemilled

on a vertical machining center. The casting is cm long, and the face mill has a diameter of

cm and, hence, a contact length of cm The speed of the casting on the machining center is

for the rough cut and for the finish cut. The time to load the casting

is sec and the unload time is sec The shop operates two shifts days a week for

weeks a year. Each shift has hours of available operating time. Operators can tend two

vertical machining centers at once without delaying the cycle time. If the demand for the cast

parts is per year, the number of vertical machining centers and operators is most

nearly:

O A machining centers and operator

O B machining centers and operators

O C machining centers and operators

O D machining centers and operators

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock