Question: The question is provided below, with context Case: AGGREGATE PLANNING Denition In these models, the workforce level is allowed to change each period through the

The question is provided below, with context

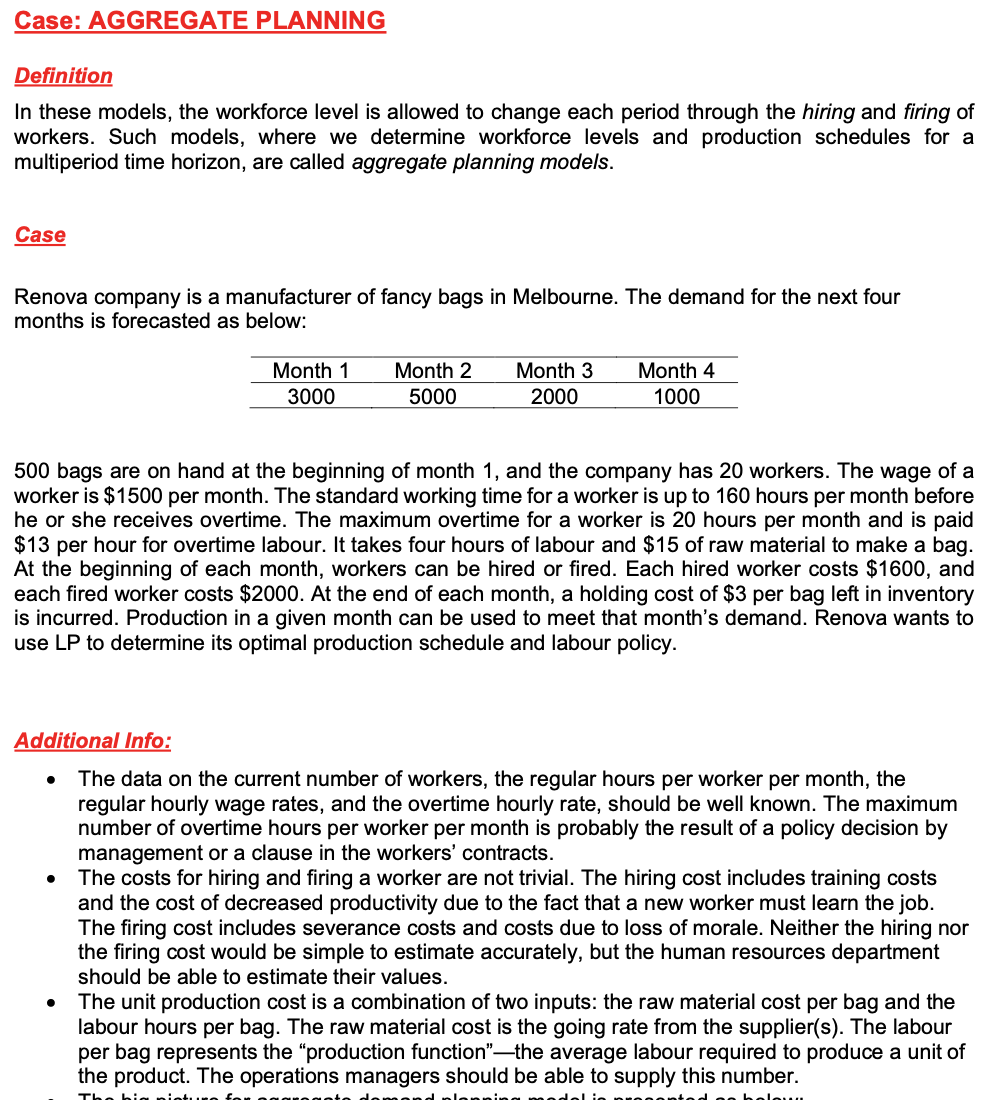

Case: AGGREGATE PLANNING Denition In these models, the workforce level is allowed to change each period through the hiring and firing of workers. Such models, where we determine workforce levels and production schedules for a multi period time horizon. are called aggregate planning modeis. Case Renova company is a manufacturer of fancy bags in Melbourne. The demand for the next four months is forecasted as below: Month 1 Month 2 Month 3 Month 4 3000 5000 2000 1000 500 bags are on hand at the beginning of month 1. and the company has 20 workers. The wage of a worker is $1500 per month. The standard working time fora worker is up to 160 hours per month before he or she receives overtime. The maximum overtime for a worker is 20 hours per month and is paid $13 per hour for overtime labour. It takes four hours of labour and $15 of raw material to make a bag. At the beginning of each month, workers can be hired or red. Each hired worker costs $1600, and each red worker costs $2000. At the end of each month, a holding cost of $3 per bag left in inventory is incurred. Production in a given month can be used to meet that month's demand. Renova wants to use LP to determine its optimal production schedule and labour policy. Additional info: 0 The data on the current number of workers, the regular hours per worker per month, the regular hourly wage rates. and the overtime hourly rate. should be well known. The maximum number of overtime hours per worker per month is probably the result of a policy decision by management or a clause in the workers' contracts. 0 The costs for hiring and ring a worker are not trivial. The hiring cost includes training costs and the cost of decreased productivity due to the fact that a new worker must learn the job. The ring cost includes severance costs and costs due to loss of morale. Neither the hiring nor the ring cost would be simple to estimate accurately, but the human resources department should be able to estimate their values. 0 The unit production cost is a combination of two inputs: the raw material cost per bag and the labour hours per bag. The raw material cost is the going rate from the supplier(s). The labour per bag represents the "production function"the average labour required to produce a unit of the product. The operations managers should be able to supply this number. _ 'l'k- L:.. -l-J..-_ I..- -A-----l_ J_u-_.J -I-__l..... \"AA-I :. .....-......L...J -- I..-I_..u. 1. Developing Mathematical Model Develop a LP model that relates workforce and production decisions to monthly costs. and to nd the minimum-cost solution that meets forecasted demands on time and stays within limits on overtime hours and production capacity. (6 marks Word Document}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts