Question: The same part can be made by die casting process. The process needs the same furnace as in Problem 1, and additionally it needs

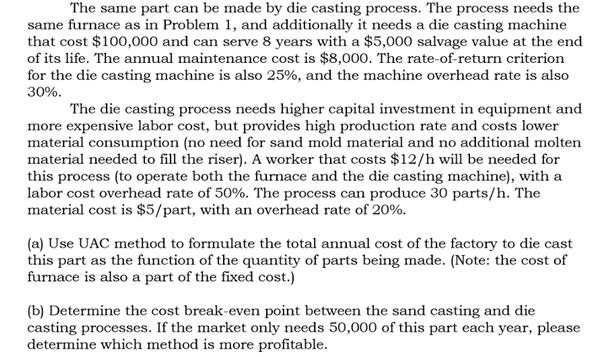

The same part can be made by die casting process. The process needs the same furnace as in Problem 1, and additionally it needs a die casting machine that cost $100,000 and can serve 8 years with a $5,000 salvage value at the end of its life. The annual maintenance cost is $8,000. The rate-of-return criterion for the die casting machine is also 25%, and the machine overhead rate is also 30%. The die casting process needs higher capital investment in equipment and more expensive labor cost, but provides high production rate and costs lower material consumption (no need for sand mold material and no additional molten material needed to fill the riser). A worker that costs $12/h will be needed for this process (to operate both the furnace and the die casting machine), with a labor cost overhead rate of 50%. The process can produce 30 parts/h. The material cost is $5/part, with an overhead rate of 20%. (a) Use UAC method to formulate the total annual cost of the factory to die cast this part as the function of the quantity of parts being made. (Note: the cost of furnace is also a part of the fixed cost.) (b) Determine the cost break-even point between the sand casting and die casting processes. If the market only needs 50,000 of this part each year, please determine which method is more profitable.

Step by Step Solution

3.50 Rating (153 Votes )

There are 3 Steps involved in it

a Use UAC method to formulate the total annual cost of the factory to die cast this part as the func... View full answer

Get step-by-step solutions from verified subject matter experts