Question: the solution was not correct by the last expert smh Arthur Meiners is the production manager of Wheel-Rite, a small producer of metal parts. Wheel-Rite

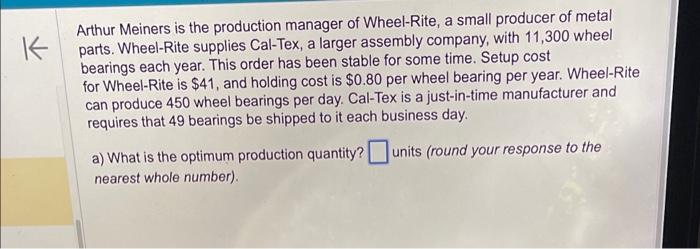

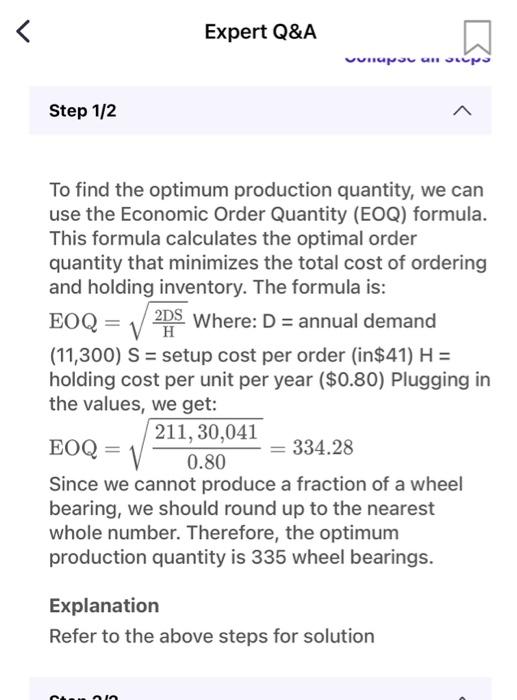

Arthur Meiners is the production manager of Wheel-Rite, a small producer of metal parts. Wheel-Rite supplies Cal-Tex, a larger assembly company, with 11,300 wheel bearings each year. This order has been stable for some time. Setup cost for Wheel-Rite is $41, and holding cost is $0.80 per wheel bearing per year. Wheel-Rite can produce 450 wheel bearings per day. Cal-Tex is a just-in-time manufacturer and requires that 49 bearings be shipped to it each business day. a) What is the optimum production quantity? units (round your response to the nearest whole number). To find the optimum production quantity, we can use the Economic Order Quantity (EOQ) formula. This formula calculates the optimal order quantity that minimizes the total cost of ordering and holding inventory. The formula is: EOQ=H2DS Where: D= annual demand (11,300)S= setup cost per order (in\$41) H= holding cost per unit per year ($0.80) Plugging in the values, we get: EOQ=0.80211,30,041=334.28 Since we cannot produce a fraction of a wheel bearing, we should round up to the nearest whole number. Therefore, the optimum production quantity is 335 wheel bearings. Explanation Refer to the above steps for solution

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts