Question: The total overtime production cost = $ (Enter your response as a whole number.) The total inventory holding cost for January through August =

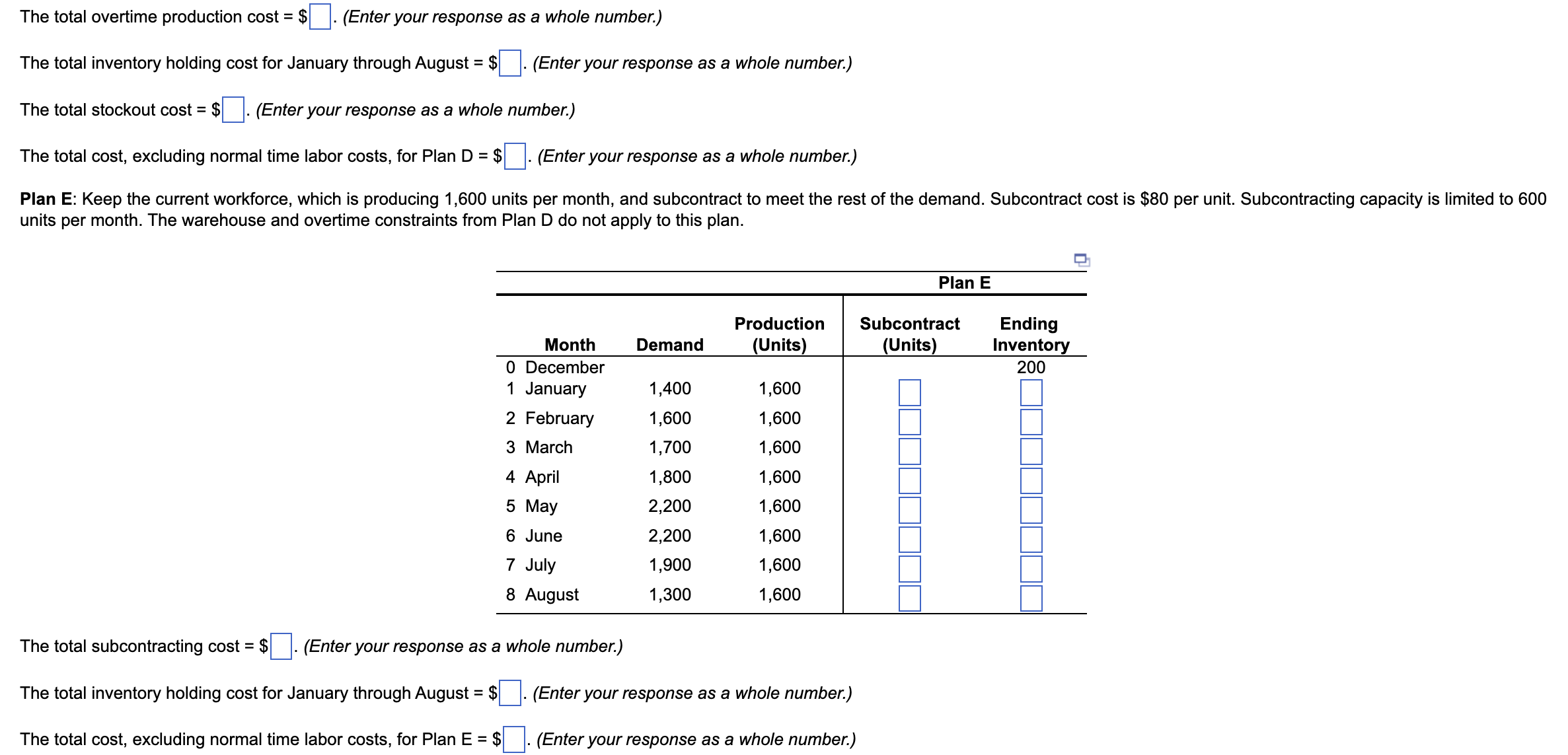

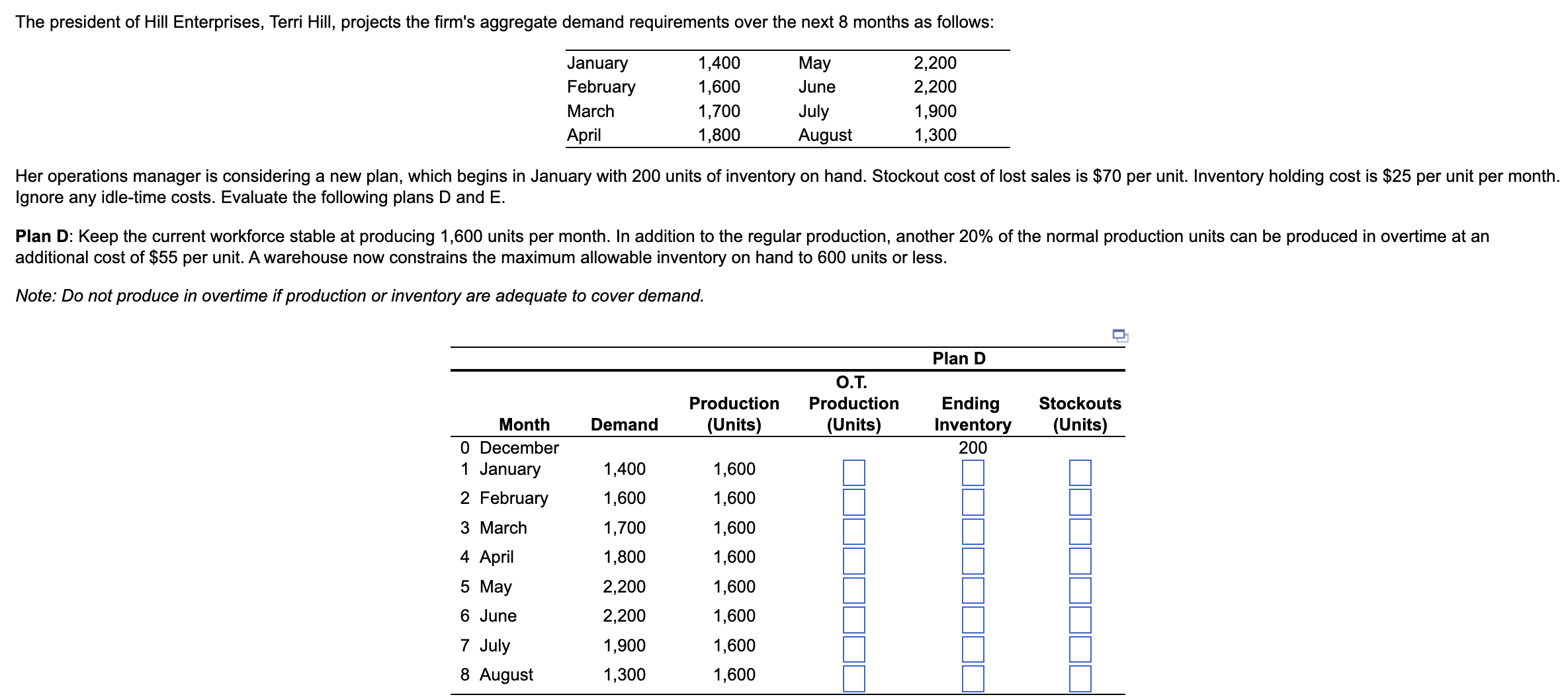

The total overtime production cost = $ (Enter your response as a whole number.) The total inventory holding cost for January through August = $ (Enter your response as a whole number.) The total stockout cost = $ (Enter your response as a whole number.) The total cost, excluding normal time labor costs, for Plan D = $ (Enter your response as a whole number.) Plan E: Keep the current workforce, which is producing 1,600 units per month, and subcontract to meet the rest of the demand. Subcontract cost is $80 per unit. Subcontracting capacity is limited to 600 units per month. The warehouse and overtime constraints from Plan D do not apply to this plan. Plan E Month Demand Production (Units) Subcontract (Units) 0 December Ending Inventory 200 1 January 1,400 1,600 2 February 1,600 1,600 3 March 1,700 1,600 4 April 1,800 1,600 5 May 2,200 1,600 6 June 2,200 1,600 7 July 1,900 1,600 8 August 1,300 1,600 The total subcontracting cost = $ (Enter your response as a whole number.) The total inventory holding cost for January through August = $ The total cost, excluding normal time labor costs, for Plan E = $ (Enter your response as a whole number.) (Enter your response as a whole number.) The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: January February March April 1,400 May 2,200 1,600 June 2,200 1,700 1,800 July August 1,900 1,300 Her operations manager is considering a new plan, which begins in January with 200 units of inventory on hand. Stockout cost of lost sales is $70 per unit. Inventory holding cost is $25 per unit per month. Ignore any idle-time costs. Evaluate the following plans D and E. Plan D: Keep the current workforce stable at producing 1,600 units per month. In addition to the regular production, another 20% of the normal production units can be produced in overtime at an additional cost of $55 per unit. A warehouse now constrains the maximum allowable inventory on hand to 600 units or less. Note: Do not produce in overtime if production or inventory are adequate to cover demand. Plan D Month Demand Production (Units) O.T. Production (Units) 0 December Ending Inventory (Units) 200 Stockouts 1 January 1,400 1,600 2 February 1,600 1,600 3 March 1,700 1,600 4 April 1,800 1,600 5 May 2,200 1,600 6 June 2,200 1,600 7 July 1,900 1,600 8 August 1,300 1,600

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts