Question: There is a sample project in the photos below. The issue is different in that project. My topic is: To open new bank branch. Can

There is a sample project in the photos below. The issue is different in that project. My topic is: "To open new bank branch". Can you make my topic according to the project I sent you? Do the same steps for my project as you did in this project. We can make up the data ourselves. We must specify the data we selected. thanks. Course name: Cost analysis and engineering management

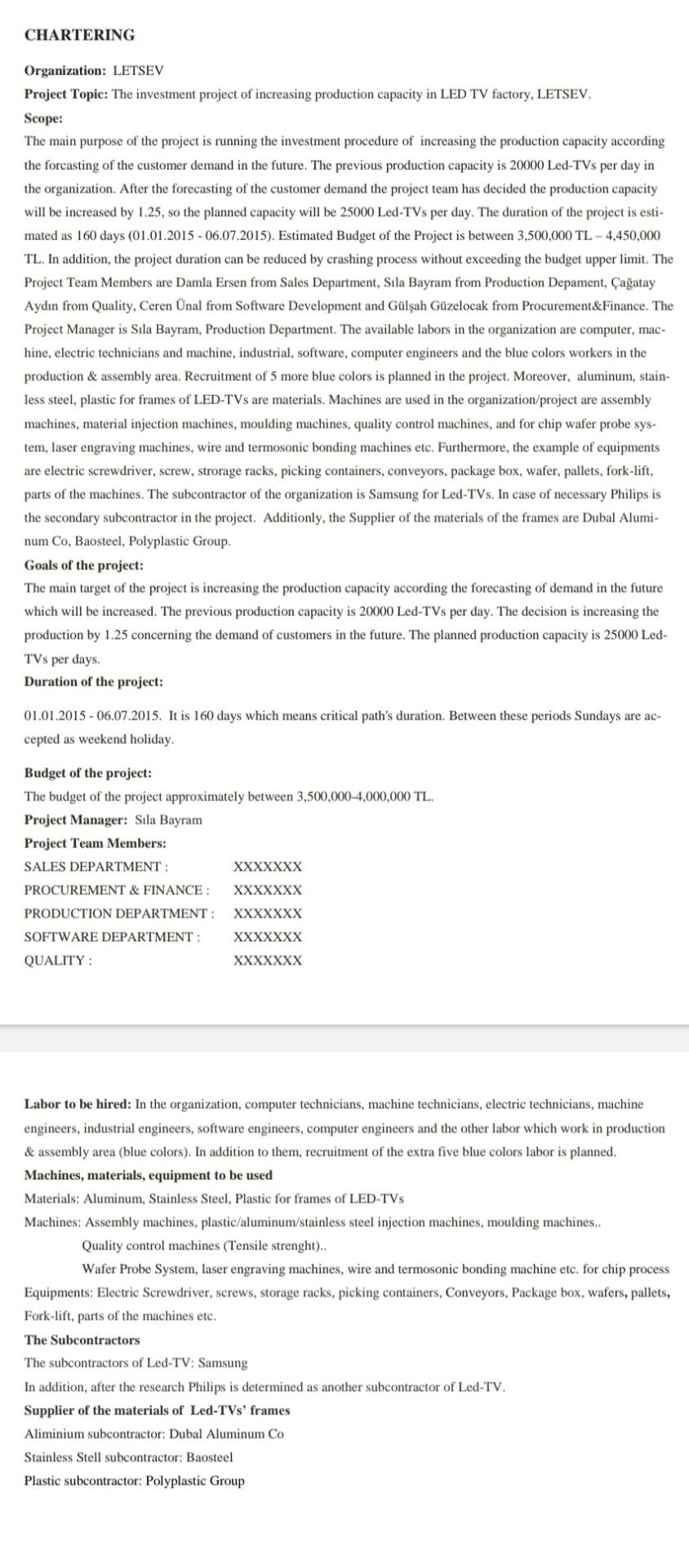

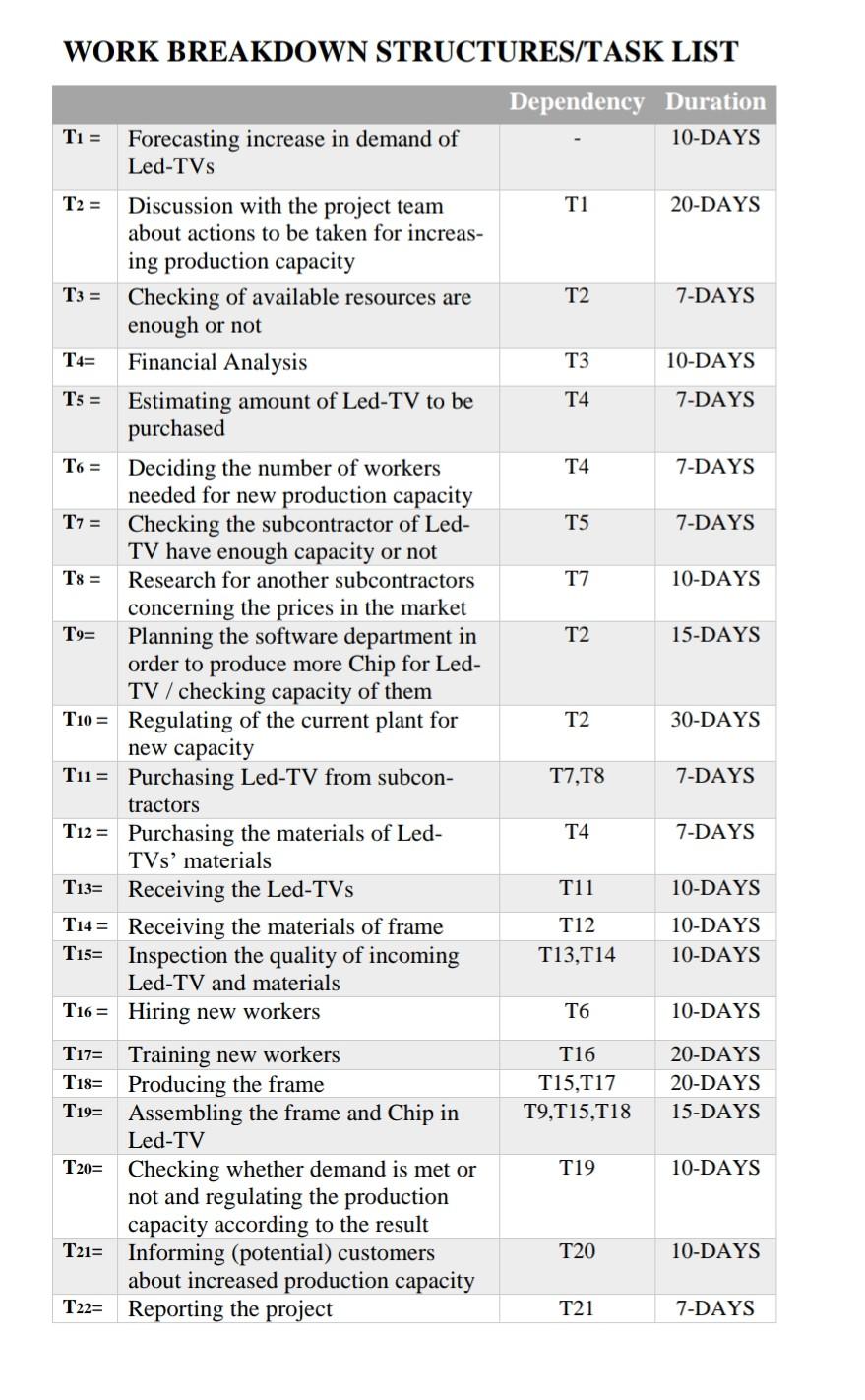

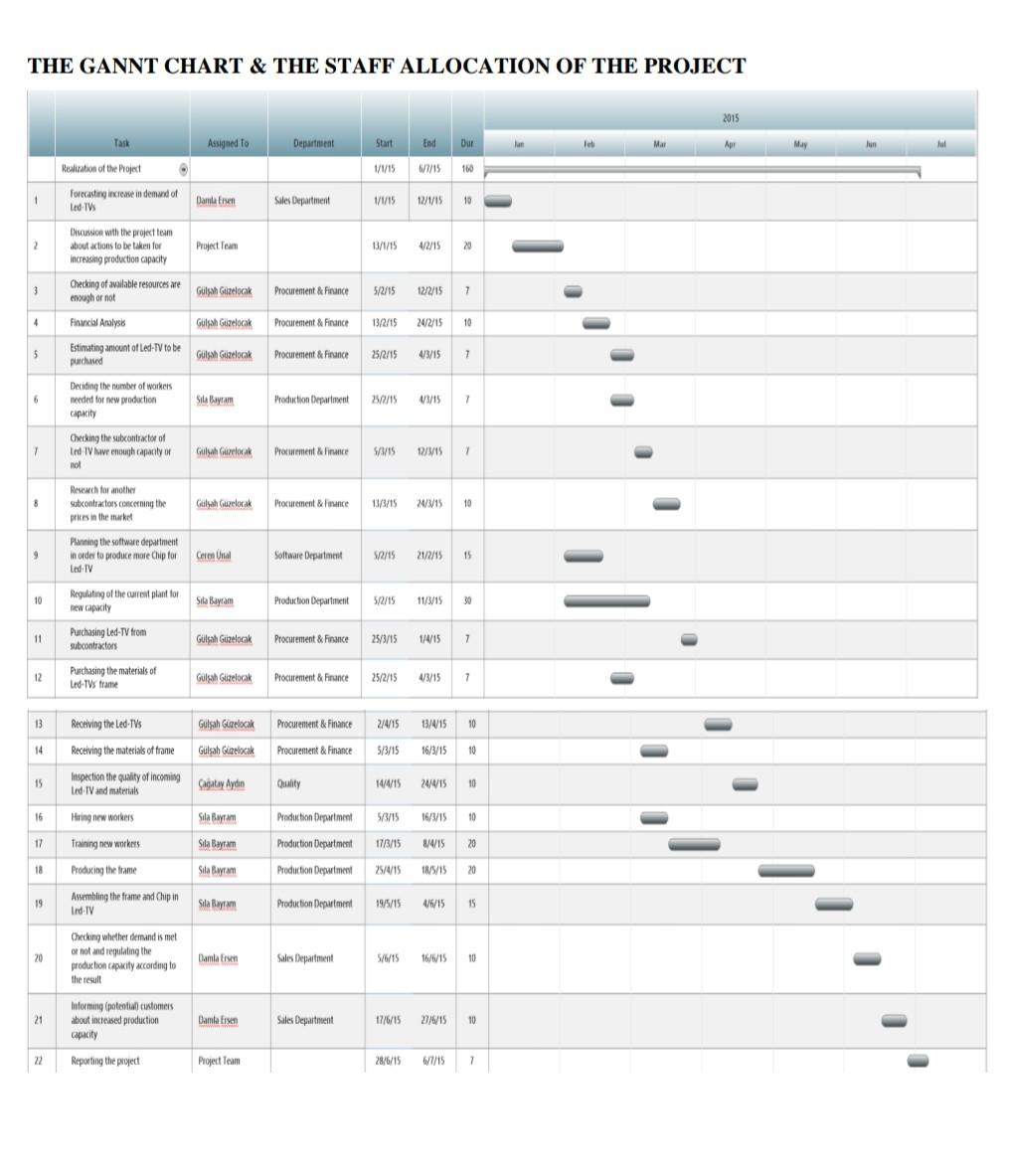

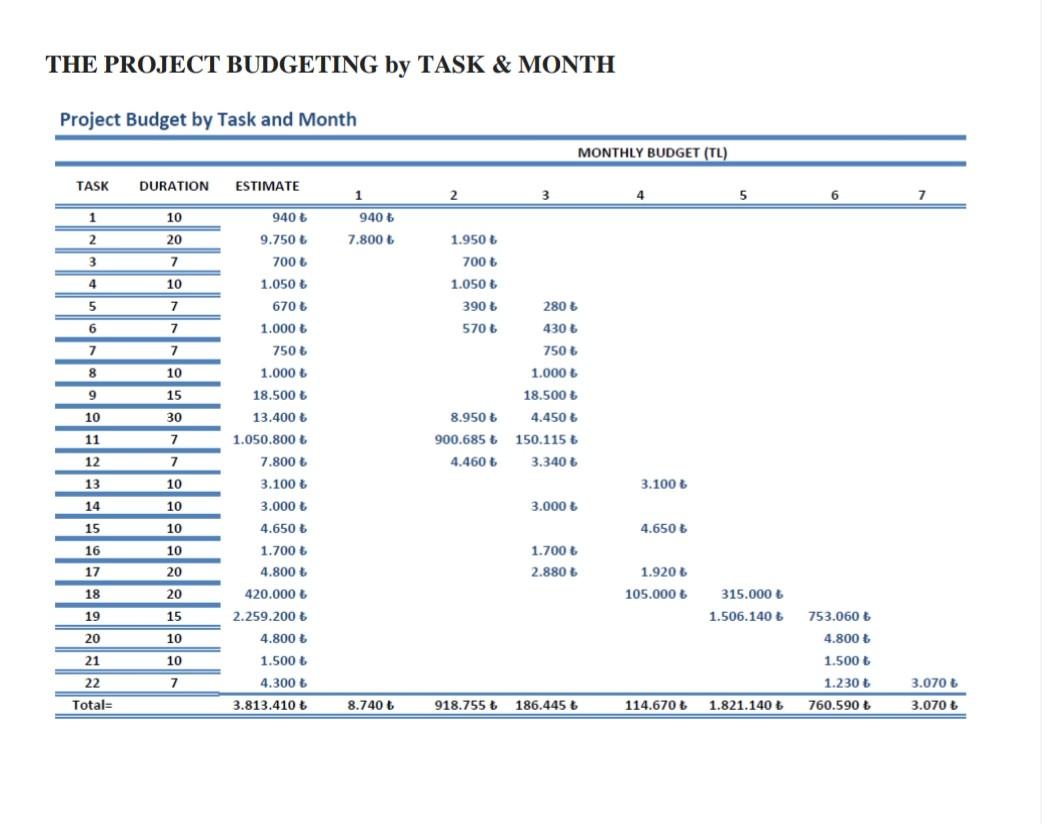

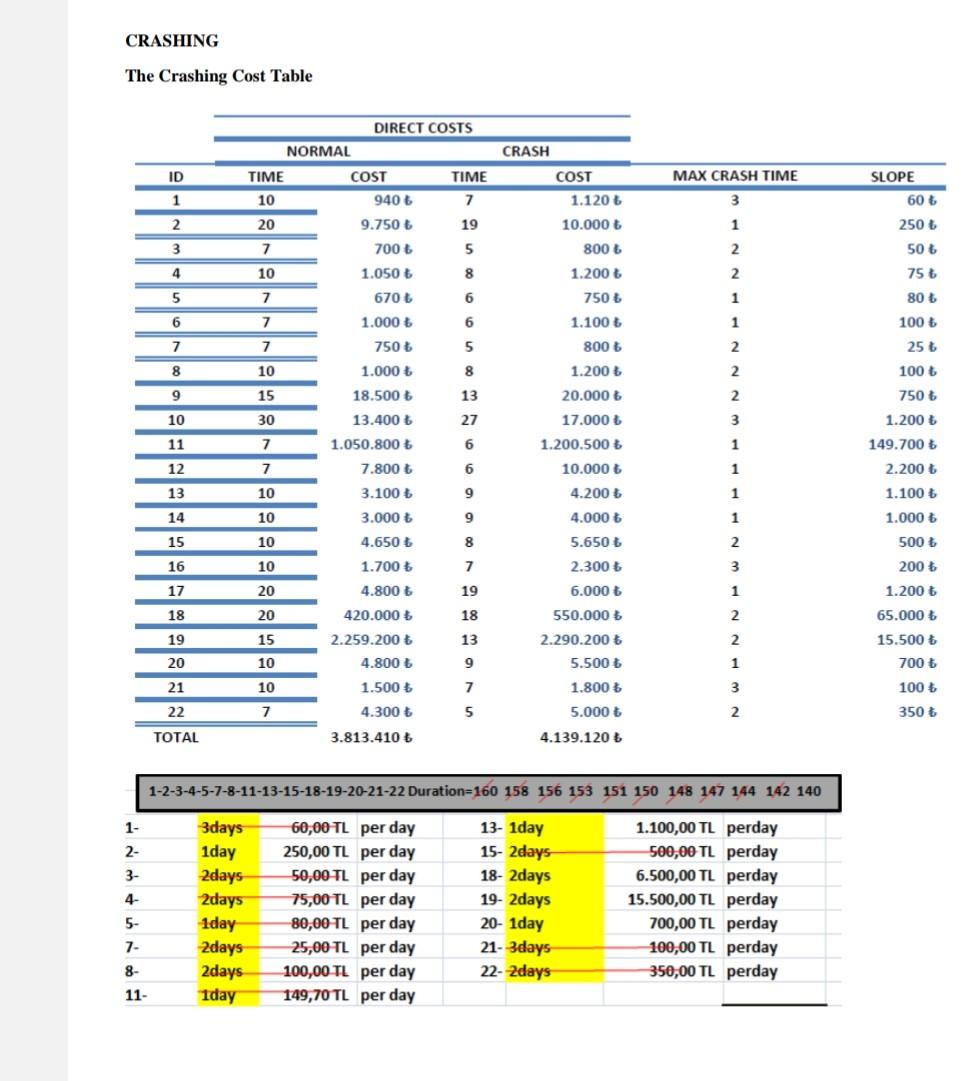

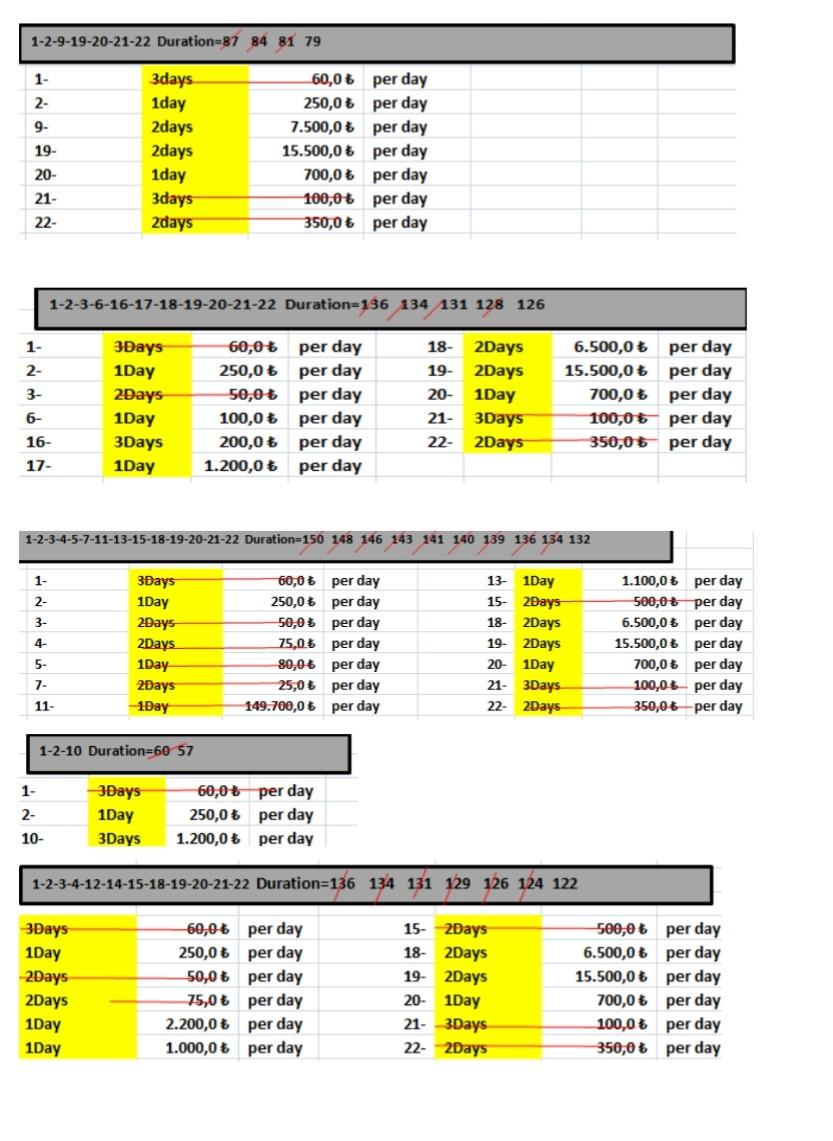

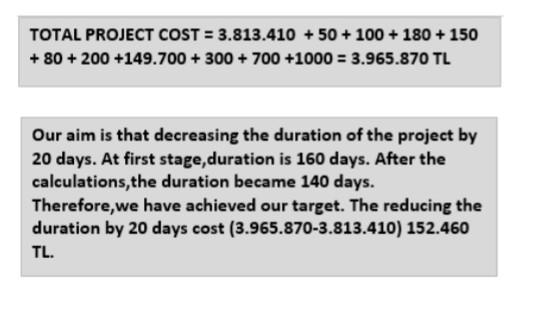

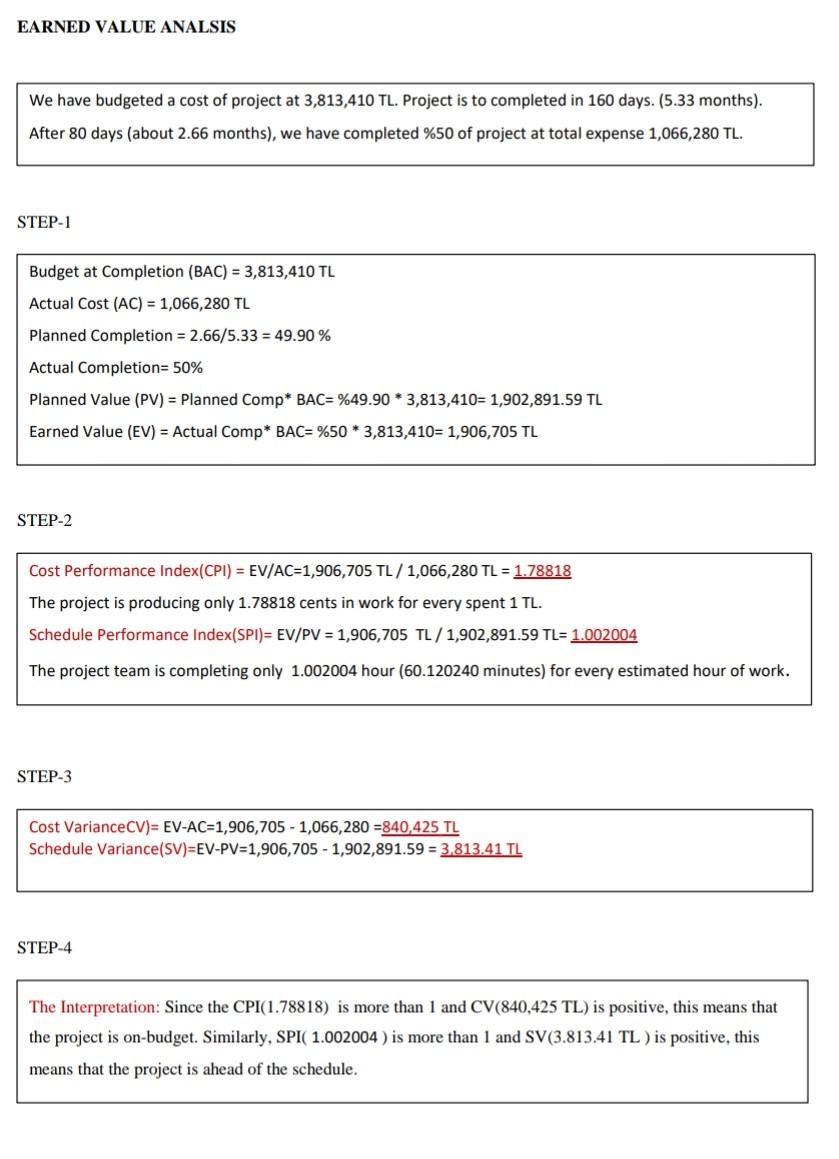

CHARTERING Organization: LETSEV Project Topic: The investment project of increasing production capacity in LED TV factory, LETSEV. Scope: The main purpose of the project is running the investment procedure of increasing the production capacity according the forcasting of the customer demand in the future. The previous production capacity is 20000 Led-TVs per day in the organization. After the forecasting of the customer demand the project team has decided the production capacity will be increased by 1.25 , so the planned capacity will be 25000 Led-TVs per day. The duration of the project is estimated as 160 days (01.01.2015 - 06.07.2015). Estimated Budget of the Project is between 3,500,000 TL - 4,450,000 TL. In addition, the project duration can be reduced by crashing process without exceeding the budget upper limit. The Project Team Members are Damla Ersen from Sales Department, Sila Bayram from Production Depament, aatay Aydn from Quality, Ceren nal from Software Development and Glah Gzelocak from Procurement\&Finance. The Project Manager is Sila Bayram, Production Department. The available labors in the organization are computer, machine, electric technicians and machine, industrial, software, computer engineers and the blue colors workers in the production \& assembly area. Recruitment of 5 more blue colors is planned in the project. Moreover, aluminum, stainless steel, plastic for frames of LED-TVs are materials. Machines are used in the organization/project are assembly machines, material injection machines, moulding machines, quality control machines, and for chip wafer probe system, laser engraving machines, wire and termosonic bonding machines etc. Furthermore, the example of equipments are electric screwdriver, screw, strorage racks, picking containers, conveyors, package box, wafer, pallets, fork-lift, parts of the machines. The subcontractor of the organization is Samsung for Led-TVs. In case of necessary Philips is the secondary subcontractor in the project. Additionly, the Supplier of the materials of the frames are Dubal Aluminum Co, Baosteel, Polyplastic Group. Goals of the project: The main target of the project is increasing the production capacity according the forecasting of demand in the future which will be increased. The previous production capacity is 20000 Led-TVs per day. The decision is increasing the production by 1.25 concerning the demand of customers in the future. The planned production capacity is 25000 LedTVs per days. Duration of the project: 01.01.2015 - 06.07.2015. It is 160 days which means critical path's duration. Between these periods Sundays are accepted as weekend holiday. Budget of the project: The budget of the project approximately between 3,500,000-4,000,000 TL. Project Manager: Stla Bayram Project Team Members: SALES DEPARTMENT : XXXXXXX PROCUREMENT \& FINANCE : XXXXXXX PRODUCTION DEPARTMENT : XXXXXXX SOFTWARE DEPARTMENT : XXXXXXX QUALITY: XXXXXXX Labor to be hired: In the organization, computer technicians, machine technicians, electric technicians, machine engineers, industrial engineers, software engineers, computer engineers and the other labor which work in production \& assembly area (blue colors). In addition to them, recruitment of the extra five blue colors labor is planned. Machines, materials, equipment to be used Materials: Aluminum, Stainless Steel, Plastic for frames of LED-TVs Machines: Assembly machines, plastic/aluminum/stainless steel injection machines, moulding machines.. Quality control machines (Tensile strenght).. Wafer Probe System, laser engraving machines, wire and termosonic bonding machine etc. for chip process Equipments: Electric Screwdriver, screws, storage racks, picking containers, Conveyors, Package box, wafers, pallets, Fork-lift, parts of the machines etc. The Subcontractors The subcontractors of Led-TV: Samsung In addition, after the research Philips is determined as another subcontractor of Led-TV. Supplier of the materials of Led-TVs' frames Aliminium subcontractor: Dubal Aluminum Co Stainless Stell subcontractor: Baosteel Plastic subcontractor: Polyplastic Group WORK BREAKDOWN STRUCTURES/TASK LIST \begin{tabular}{|c|c|c|c|} \hline & & Dependency & Duration \\ \hline T1= & \begin{tabular}{l} Forecasting increase in demand of \\ Led-TVs \end{tabular} & - & 10-DAYS \\ \hline T2= & \begin{tabular}{l} Discussion with the project team \\ about actions to be taken for increas- \\ ing production capacity \end{tabular} & T1 & 20-DAYS \\ \hline T3= & \begin{tabular}{l} Checking of available resources are \\ enough or not \end{tabular} & T2 & 7-DAYS \\ \hline T4= & Financial Analysis & T3 & 10-DAYS \\ \hline T5= & \begin{tabular}{l} Estimating amount of Led-TV to be \\ purchased \end{tabular} & T4 & 7-DAYS \\ \hlineT6= & \begin{tabular}{l} Deciding the number of workers \\ needed for new production capacity \end{tabular} & T4 & 7-DAYS \\ \hline T7= & \begin{tabular}{l} Checking the subcontractor of Led- \\ TV have enough capacity or not \end{tabular} & T5 & 7-DAYS \\ \hline T8= & \begin{tabular}{l} Research for another subcontractors \\ concerning the prices in the market \end{tabular} & T7 & 10-DAYS \\ \hline T9= & \begin{tabular}{l} Planning the software department in \\ order to produce more Chip for Led- \\ TV / checking capacity of them \end{tabular} & T2 & 15-DAYS \\ \hline T10= & \begin{tabular}{l} Regulating of the current plant for \\ new capacity \end{tabular} & T2 & 30-DAYS \\ \hline T11= & \begin{tabular}{l} Purchasing Led-TV from subcon- \\ tractors \end{tabular} & T7,T8 & 7-DAYS \\ \hline T12= & \begin{tabular}{l} Purchasing the materials of Led- \\ TVs' materials \end{tabular} & T4 & 7-DAYS \\ \hline T13= & Receiving the Led-TVs & T11 & 10-DAYS \\ \hline T14= & Receiving the materials of f & T12 & 10-DAYS \\ \hline T15= & \begin{tabular}{l} Inspection the quality of incoming \\ Led-TV and materials \end{tabular} & T13,T14 & 10-DAYS \\ \hline T16= & Hiring new workers & T6 & 10-DAYS \\ \hline T17= & Training new workers & T1 & 20-DAYS \\ \hline T18= & Producing the frame & T15,T17 & 20-DAYS \\ \hlineT19= & \begin{tabular}{l} Assembling the frame and Chip in \\ Led-TV \end{tabular} & T9,T15,T18 & 15-DAYS \\ \hline T20= & \begin{tabular}{l} Checking whether demand is met or \\ not and regulating the production \\ capacity according to the result \end{tabular} & T19 & 10-DAYS \\ \hline T21= & \begin{tabular}{l} Informing (potential) customers \\ about increased production capacity \end{tabular} & T20 & 10-DAYS \\ \hlineT22= & Reporting the project & T21 & 7-DAYS \\ \hline \end{tabular} THE GANNT CHART \& THE STAFF ALLOCATION OF THE PROJECT THE PROJECT BUDGETING by TASK \& MONTH Network Diagram with all information as stated in lecture notes. CRITICAL PATH Slacks and Floats Total Float of Tasks TF=LS-FS CRASHING The Crashing Cost Table \begin{tabular}{|c|c|c|c|c|c|c|c|} \hline & 16171 & 9202122 & Duration=1 & 4/13 & 12812 & & \\ \hline 1- & ays & 60,05 & per day & 18 & 2Days & 6.500,0 & per day \\ \hline 2- & 1Day & 250,0 & per day & 19 & 2Days & 15.500,0 & per day \\ \hline 3- & 2Days & 50,06 & per day & 20 & 1Day & 700,06 & per day \\ \hline 6- & 1Day & 100,0 & per day & 21- & 3Days & 100,06 & per day \\ \hline 16 & 3Days & 200,0 & per day & 22 & 2Days & 350,0 & per day \\ \hline 17 & 1Day & 1.200,06 & per day & & & & \\ \hline \end{tabular} TOTAL PROJECT COST =3.813.410+50+100+180+150 +80+200+149.700+300+700+1000=3.965.870TL Our aim is that decreasing the duration of the project by 20 days. At first stage,duration is 160 days. After the calculations, the duration became 140 days. Therefore, we have achieved our target. The reducing the duration by 20 days cost (3.965.8703.813.410) 152.460 TL. We have budgeted a cost of project at 3,813,410 TL. Project is to completed in 160 days. (5.33 months). After 80 days (about 2.66 months), we have completed %50 of project at total expense 1,066,280 TL. STEP-1 Budget at Completion (BAC)=3,813,410TL Actual Cost (AC)=1,066,280TL Planned Completion =2.66/5.33=49.90% Actual Completion =50% Planned Value (PV) = Planned Comp* BAC =%49.903,813,410=1,902,891.59TL Earned Value (EV) = Actual Comp* BAC =%503,813,410=1,906,705TL STEP-2 Cost Performance Index(CPI) =EV/AC=1,906,705TL/1,066,280TL=1.78818 The project is producing only 1.78818 cents in work for every spent 1TL. Schedule Performance Index(SPI)= EV/PV = 1,906,705 TL / 1,902,891.59 TL= 1.002004 The project team is completing only 1.002004 hour ( 60.120240 minutes) for every estimated hour of work. STEP-3 Cost VarianceCV) =EVAC=1,906,7051,066,280=840,425TL Schedule Variance(SV) =EVPV=1,906,7051,902,891.59=3,813.41TL STEP-4 The Interpretation: Since the CPI(1.78818) is more than 1 and CV (840,425TL) is positive, this means that the project is on-budget. Similarly, SPI 1.002004 ) is more than 1 and SV(3.813.41 TL) is positive, this means that the project is ahead of the schedule

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts