Question: There is no lead time for E and H. A furniture company produces three types of chairs: ladder-back, kitchen and desk chairs. Assume that we

There is no lead time for E and H.

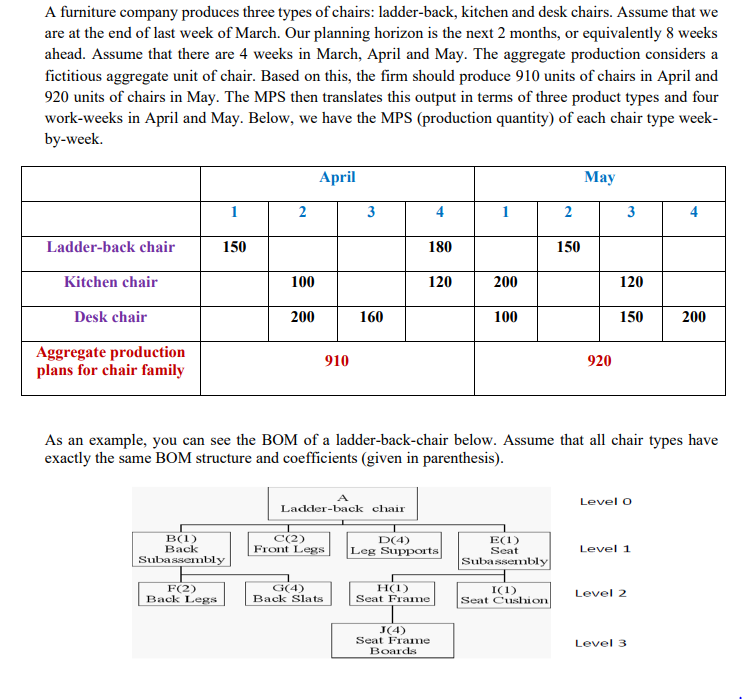

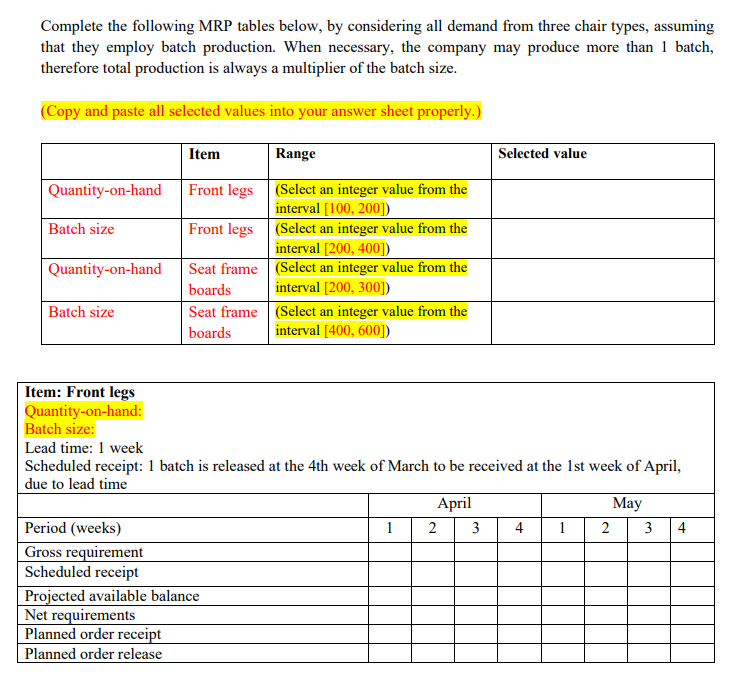

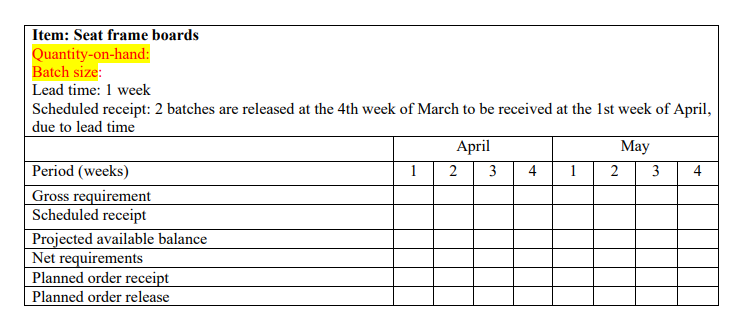

A furniture company produces three types of chairs: ladder-back, kitchen and desk chairs. Assume that we are at the end of last week of March. Our planning horizon is the next 2 months, or equivalently 8 weeks ahead. Assume that there are 4 weeks in March, April and May. The aggregate production considers a fictitious aggregate unit of chair. Based on this, the firm should produce 910 units of chairs in April and 920 units of chairs in May. The MPS then translates this output in terms of three product types and four work-weeks in April and May. Below, we have the MPS (production quantity) of each chair type week- by-week. April May 3 Ladder-back chair 150 180 150 Kitchen chair 100 120 200 120 Desk chair 200 160 100 150 200 Aggregate production plans for chair family 910 920 As an example, you can see the BOM of a ladder-back-chair below. Assume that all chair types have exactly the same BOM structure and coefficients (given in parenthesis). Level o Ladder-back chair B (1) Back Subassembly C (2) Front Legs D(4) Leg Supports E(1) Seat Subassembly Level 1 F (2) Back Legs G (4) Back Slats H (1) Seat Frame I(1) Seat Cushion Level 2 J(4) Seat Frame Boards Level 3 Complete the following MRP tables below, by considering all demand from three chair types, assuming that they employ batch production. When necessary, the company may produce more than 1 batch, therefore total production is always a multiplier of the batch size. (Copy and paste all selected values into your answer sheet properly.) Item Range Selected value Quantity-on-hand Front legs Batch size Front legs (Select an integer value from the interval [100, 2001 (Select an integer value from the interval [200, 4001) (Select an integer value from the interval [200, 300D (Select an integer value from the interval [400, 600] Quantity-on-hand Seat frame boards Seat frame boards Batch size Item: Front legs Quantity-on-hand: Batch size: Lead time: 1 week Scheduled receipt: 1 batch is released at the 4th week of March to be received at the 1st week of April, due to lead time April May Period (weeks) Gross requirement Scheduled receipt Projected available balance Net requirements Planned order receipt Planned order release Item: Seat frame boards Quantity-on-hand: Batch size: Lead time: 1 week Scheduled receipt: 2 batches are released at the 4th week of March to be received at the 1st week of April, due to lead time April May Period (weeks) 1 2 3 4 1 2 3 Gross requirement Scheduled receipt Projected available balance Net requirements Planned order receipt Planned order release A furniture company produces three types of chairs: ladder-back, kitchen and desk chairs. Assume that we are at the end of last week of March. Our planning horizon is the next 2 months, or equivalently 8 weeks ahead. Assume that there are 4 weeks in March, April and May. The aggregate production considers a fictitious aggregate unit of chair. Based on this, the firm should produce 910 units of chairs in April and 920 units of chairs in May. The MPS then translates this output in terms of three product types and four work-weeks in April and May. Below, we have the MPS (production quantity) of each chair type week- by-week. April May 3 Ladder-back chair 150 180 150 Kitchen chair 100 120 200 120 Desk chair 200 160 100 150 200 Aggregate production plans for chair family 910 920 As an example, you can see the BOM of a ladder-back-chair below. Assume that all chair types have exactly the same BOM structure and coefficients (given in parenthesis). Level o Ladder-back chair B (1) Back Subassembly C (2) Front Legs D(4) Leg Supports E(1) Seat Subassembly Level 1 F (2) Back Legs G (4) Back Slats H (1) Seat Frame I(1) Seat Cushion Level 2 J(4) Seat Frame Boards Level 3 Complete the following MRP tables below, by considering all demand from three chair types, assuming that they employ batch production. When necessary, the company may produce more than 1 batch, therefore total production is always a multiplier of the batch size. (Copy and paste all selected values into your answer sheet properly.) Item Range Selected value Quantity-on-hand Front legs Batch size Front legs (Select an integer value from the interval [100, 2001 (Select an integer value from the interval [200, 4001) (Select an integer value from the interval [200, 300D (Select an integer value from the interval [400, 600] Quantity-on-hand Seat frame boards Seat frame boards Batch size Item: Front legs Quantity-on-hand: Batch size: Lead time: 1 week Scheduled receipt: 1 batch is released at the 4th week of March to be received at the 1st week of April, due to lead time April May Period (weeks) Gross requirement Scheduled receipt Projected available balance Net requirements Planned order receipt Planned order release Item: Seat frame boards Quantity-on-hand: Batch size: Lead time: 1 week Scheduled receipt: 2 batches are released at the 4th week of March to be received at the 1st week of April, due to lead time April May Period (weeks) 1 2 3 4 1 2 3 Gross requirement Scheduled receipt Projected available balance Net requirements Planned order receipt Planned order releaseStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock