Question: these are aerospace precision core values, what are some ways to enahmce these values if the company has been decreasing in revemue and has poor

these are aerospace precision core values, what are some ways to enahmce these values if the company has been decreasing in revemue and has poor management and bad culture ?

i hope this helps

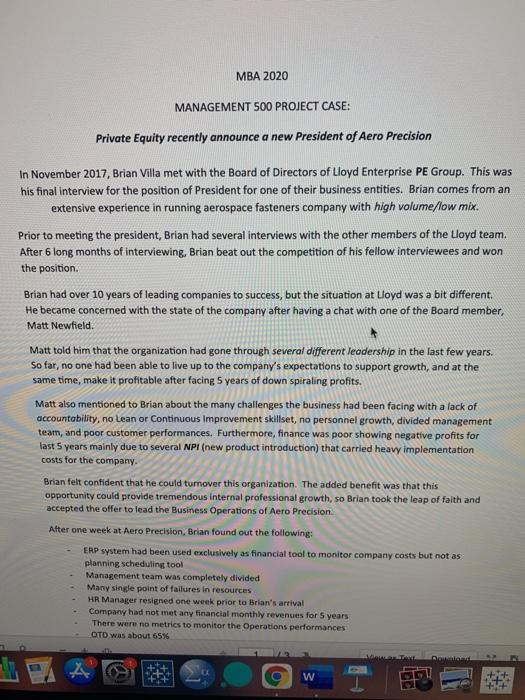

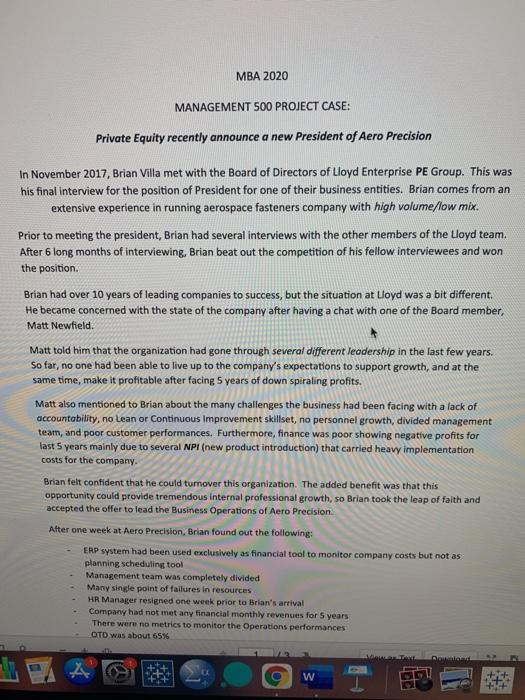

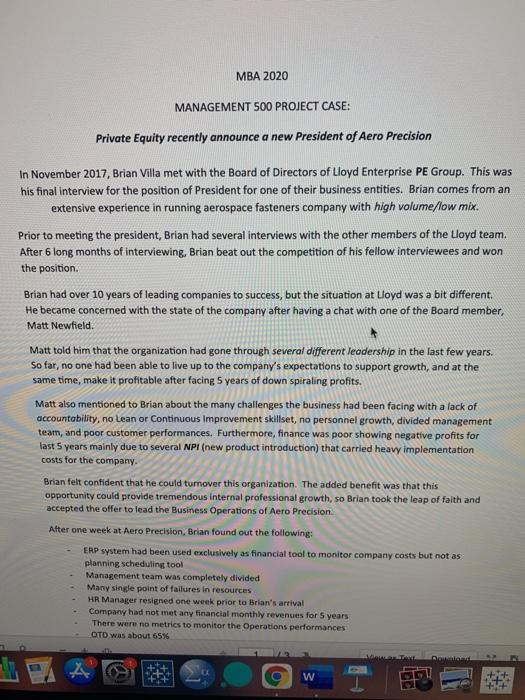

Core Values Integrity Customers Talk, We Listen Respectful Engagement Best Team Wins Transparency Continuous Improvement MBA 2020 MANAGEMENT 500 PROJECT CASE: Private Equity recently announce a new President of Aero Precision In November 2017, Brian Villa met with the Board of Directors of Lloyd Enterprise PE Group. This was his final interview for the position of President for one of their business entities. Brian comes from an extensive experience in running aerospace fasteners company with high volume/low mix. Prior to meeting the president, Brian had several interviews with the other members of the Lloyd team. After 6 long months of interviewing, Brian beat out the competition of his fellow interviewees and won the position Brian had over 10 years of leading companies to success, but the situation at Lloyd was a bit different. He became concerned with the state of the company after having a chat with one of the Board member, Matt Newfield. Matt told him that the organization had gone through several different leadership in the last few years. So far, no one had been able to live up to the company's expectations to support growth, and at the same time, make it profitable after facing 5 years of down spiraling profits. Matt also mentioned to Brian about the many challenges the business had been facing with a lack of accountability, no Lean or Continuous Improvement skillset, no personnel growth, divided management team, and poor customer performances. Furthermore, finance was poor showing negative profits for last 5 years mainly due to several NPI (new product introduction) that carried heavy implementation costs for the company. Brian felt confident that he could turnover this organization. The added benefit was that this opportunity could provide tremendous internal professional growth, so Brian took the leap of faith and accepted the offer to lead the Business Operations of Aero Precision After one week at Aero Precision, Brian found out the following: ERP system had been used exclusively as financial tool to monitor company costs but not as planning scheduling tool Management team was completely divided Many single point of failures in resources HR Manager resigned one week prior to Brian's arrival Company had not met any financial monthly revenues for 5 years There were no metrics to monitor the Operations performances OTD was about 65% Download W IR ++ - There was no clear identity of vision and mission of the company Everybody acted reactively and was constantly fighting fires Scrap was over 10% of revenue Rework was at 20% of revenue There was an average of 20 returned parts a month with an average of 450 pieces shipped each month of 50 different part number Most of the managers in place were not skilled to the job No training programs No bonus or employees awards or recognition for the last 3 years Machineries were down most of the time and no preventive maintenance in place No supplier's strategy. No "make or buy" analysis. Company spent more than $10M in last 2 years on new equipment that had not been utilized Overhead costs were 50% higher than budget There wasn't a financial controller in place for the past 3 years. Only one assistant controller handled all financial affairs Business was making parts to order and not to stock and the Lead Time was over 4 months in average Products were in low volume between 4 and 20 pcs per part number a month. Footprint and layout were designed adding equipment where space was found. Brian had his doubts that he could handle all the challenges of his new job. He didn't even know where to start tackling the towering issues. What would you suggest as an improvement plan to bring back the business to a positive protitability? What are the areas you would focus first? How long do you feel it would be necessary to turn around the business? In 90 days from his establishment Brian is requested to present to the PE Group a 3-5 years strategie plan to turnaround the organization and build profitable business >15% EBITDA). Based on the credibility and the strong data support you will be able to present to the PE group, you will be allowed to carry on your Project Based on the credibility and the strong data support you will be able to present to the PE group, you will be allowed to carry on your Project. Other information about the business: Revenue $60M Inventory turnover 5.0 Employees 160 Managers 11 Company sells turbine engine components for about 50 different part numbers Low volume-high mix Only 5 customers in their portfolio Supply Chain 10% of the process Lead time from 4 weeks to 3 months Material cost 35% of total revenue, Production supplies 15%, DL 15%, Overhead 45%, SG&A 5%, 5% depreciation