Question: This homework is based on Chapter 11 (cycle inventory). For all the problems, to receive full scores, you have to show your complete and accurate

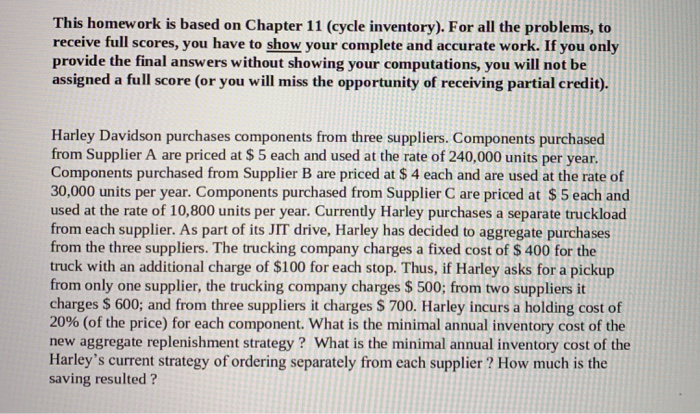

This homework is based on Chapter 11 (cycle inventory). For all the problems, to receive full scores, you have to show your complete and accurate work. If you only provide the final answers without showing your computations, you will not be assigned a full score (or you will miss the opportunity of receiving partial credit). Harley Davidson purchases components from three suppliers. Components purchased from Supplier A are priced at $ 5 each and used at the rate of 240,000 units per year. Components purchased from Supplier B are priced at $ 4 each and are used at the rate of 30,000 units per year. Components purchased from Supplier C are priced at $ 5 each and used at the rate of 10,800 units per year. Currently Harley purchases a separate truckload from each supplier. As part of its JIT drive, Harley has decided to aggregate purchases from the three suppliers. The trucking company charges a fixed cost of $ 400 for the truck with an additional charge of $100 for each stop. Thus, if Harley asks for a pickup from only one supplier, the trucking company charges $ 500; from two suppliers it charges $ 600; and from three suppliers it charges $ 700. Harley incurs a holding cost of 20% (of the price) for each component. What is the minimal annual inventory cost of the new aggregate replenishment strategy? What is the minimal annual inventory cost of the Harley's current strategy of ordering separately from each supplier ? How much is the saving resulted ? This homework is based on Chapter 11 (cycle inventory). For all the problems, to receive full scores, you have to show your complete and accurate work. If you only provide the final answers without showing your computations, you will not be assigned a full score (or you will miss the opportunity of receiving partial credit). Harley Davidson purchases components from three suppliers. Components purchased from Supplier A are priced at $ 5 each and used at the rate of 240,000 units per year. Components purchased from Supplier B are priced at $ 4 each and are used at the rate of 30,000 units per year. Components purchased from Supplier C are priced at $ 5 each and used at the rate of 10,800 units per year. Currently Harley purchases a separate truckload from each supplier. As part of its JIT drive, Harley has decided to aggregate purchases from the three suppliers. The trucking company charges a fixed cost of $ 400 for the truck with an additional charge of $100 for each stop. Thus, if Harley asks for a pickup from only one supplier, the trucking company charges $ 500; from two suppliers it charges $ 600; and from three suppliers it charges $ 700. Harley incurs a holding cost of 20% (of the price) for each component. What is the minimal annual inventory cost of the new aggregate replenishment strategy? What is the minimal annual inventory cost of the Harley's current strategy of ordering separately from each supplier ? How much is the saving resulted