Question: This is a mining enguneering question:The following cost information has been provided for pit optimization for Rocktype 1 and Rocktype 2 , but should be

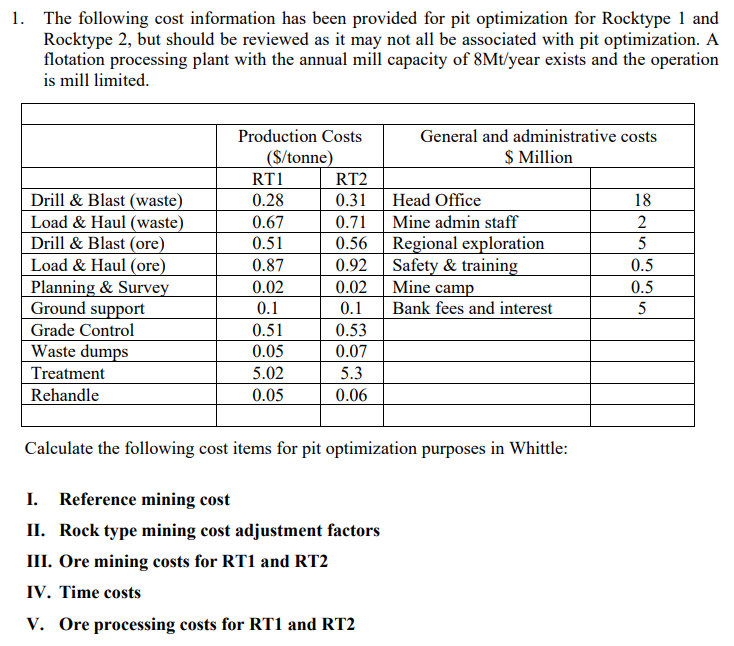

This is a mining enguneering question:The following cost information has been provided for pit optimization for Rocktype and Rocktype but should be reviewed as it may not all be associated with pit optimization. A flotation processing plant with the annual mill capacity of year exists and the operation is mill limited

tabletableProduction Costs$tonnetableSeneral and administrative costs$ MillionRTRTDrill & Blast wasteHead Office,Load & Haul wasteMine admin staff,Drill & Blast oreRegional exploration,Load & Haul oreSafety & training,Planning & Survey,Mine camp,Ground support,Bank fees and interest,Grade Control,Waste dumps,TreatmentRehandle

Calculate the following cost items for pit optimization purposes in Whittle:

I. Reference mining cost

II Rock type mining cost adjustment factors

III. Ore mining costs for RT and RT

IV Time costs

V Ore processing costs for RT and RT

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock