Question: this is all the info given for the problem Problem 1: Prepare a Master Schedule given the following information: The forecast for each week for

this is all the info given for the problem

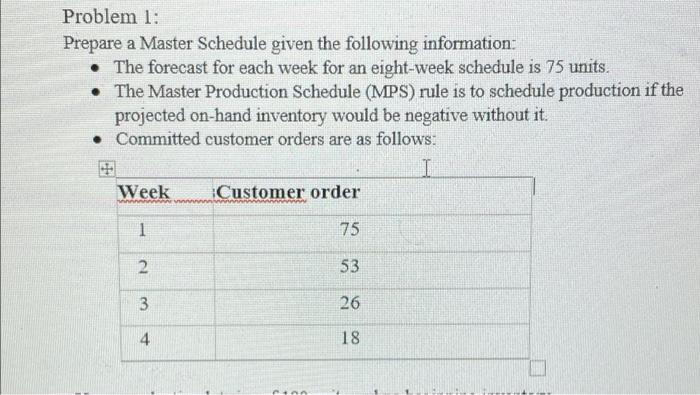

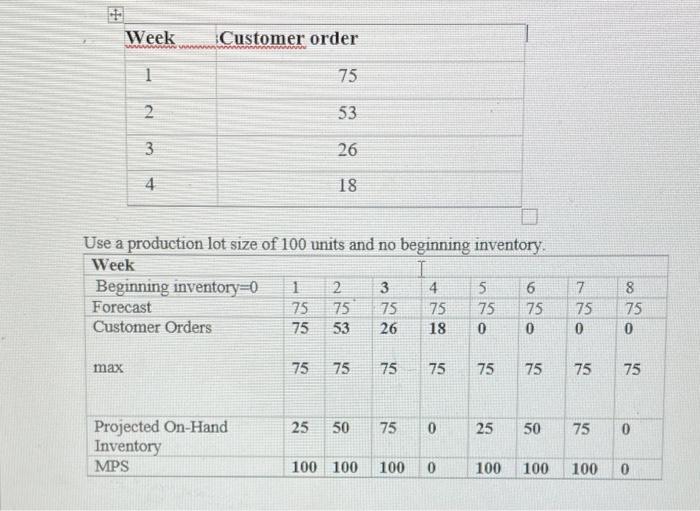

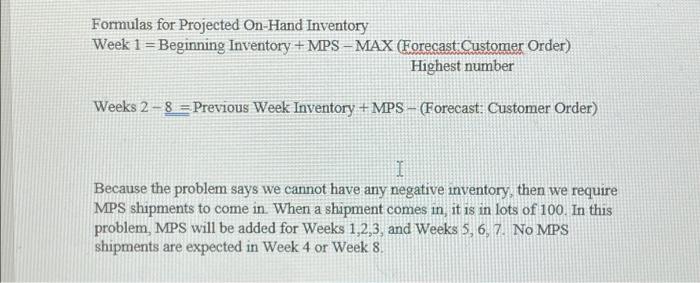

Problem 1: Prepare a Master Schedule given the following information: The forecast for each week for an eight-week schedule is 75 units. The Master Production Schedule (MPS) rule is to schedule production if the projected on-hand inventory would be negative without it. Committed customer orders are as follows: I Week Customer order 1 75 2 53 3 26 4 18 + Week Customer order 75 2 53 3 26 4 18 Use a production lot size of 100 units and no beginning inventory. Week Beginning inventory=0 1 2 3 4 5 6 Forecast 75 75 75 75 75 Customer Orders 75 53 26 18 0 7 7 75 75 8 75 0 0 max 75 75 75 75 75 75 75 75 25 50 75 0 25 50 75 0 Projected On-Hand Inventory MPS 100 100 100 0 100 100 100 0 Formulas for Projected On-Hand Inventory Week 1 = Beginning Inventory + MPS MAX (Forecast Customer Order) Highest number Weeks 2 8 = Previous Week Inventory +MPS - (Forecast: Customer Order) I Because the problem says we cannot have any negative inventory, then we require MPS shipments to come in When a shipment comes in it is in lots of 100. In this problem, MPS will be added for Weeks 1,2,3, and Weeks 5, 6, 7 No MPS shipments are expected in Week 4 or Week 8 Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock