Question: this question is OPERATIONS MANAGEMENT KSK company prepares 2 different cable assembly products. The annual production amount of the WA1 model is 50,000 units. In

this question is OPERATIONS MANAGEMENT

KSK company prepares 2 different cable assembly products. The annual production amount of the WA1 model is 50,000 units. In the past, 14,000 hours of direct labor and 6,000 hours of machine time were used to manufacture the WA1 model. The annual production amount of the WA2 model is 40,000 units and this production amount was realized with 24,000 hours of direct labor and 3000 hours of machine use.

a) Calculate the planning factors (the amount of use per unit product in the all factors method) for the following resources.

Direct labor factor for WA1 production Direct labor factor for WA2 production Machine time factor for WA1 production Machine time factor for WA2 production

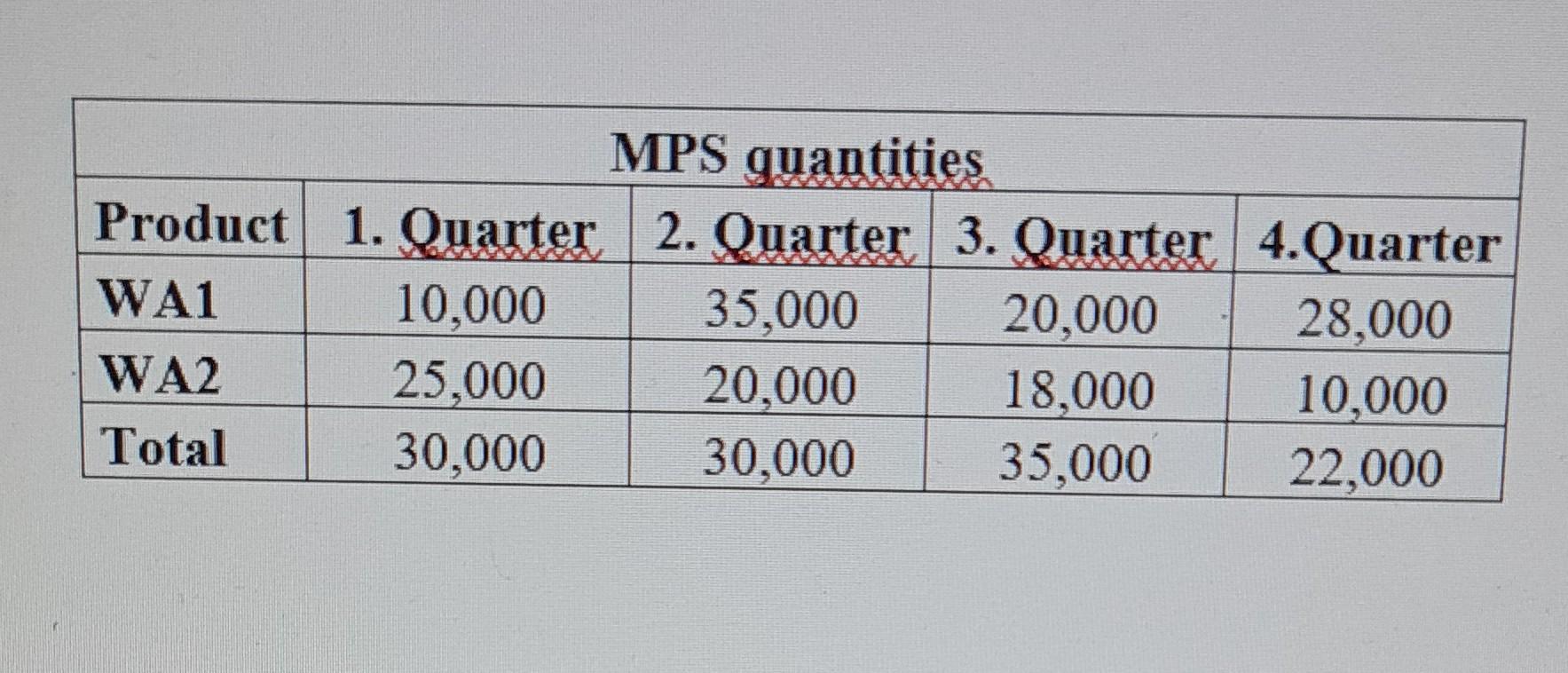

b) Calculate the direct labor and machine capacity needs for each period using the MPS amounts given below and the factors you calculated in part (a).

c) Cable assembly products are produced in 3 different departments. Direct labor and machinery are used in all of these departments. According to historical data, department 1 (WC101) accounts for 35% of the total labor and machinery capacity; 2nd department (WC102) 15%; and the 3rd department (WC103) uses 50%. In the light of this data, calculate the direct labor and machine usage needs of the three departments for each period.

MPS quantities Product 1. Quarter 2. Quarter 3. Quarter 4.Quarter WA1 10,000 35,000 20,000 28,000 WA2 25,000 20,000 18,000 10,000 Total 30,000 30,000 35,000 22,000Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts