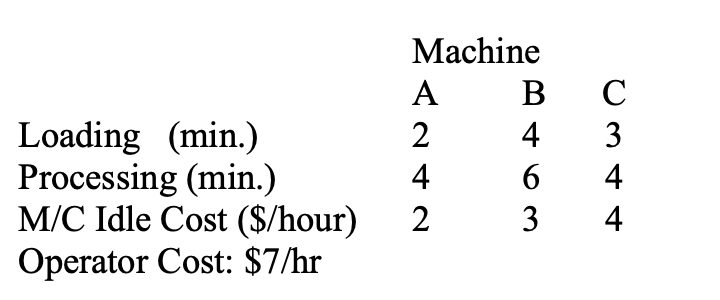

Question: Three parts processed by three different machines are needed to assemble a finished product. The table below shows production data for Machine A, Machine B,

Three parts processed by three different machines are needed to assemble a finished product. The table below shows production data for Machine A, Machine B, and Machine C (in minutes). It takes 0.5 minutes for the operator to walk from one machine to another one.

One alternative is to assign an operator to attend to all three machines.

(a) Show your machine coupling chart and calculate the total cost for this alternative.

(b) Assume that 400 minutes are available per day, and parts completed by each machine are sent to an assembly station in which the final assembly will be done. How many finished products can be completed per day?

(c) Another alternative is to use one operator to attend all three machines. Show your machine coupling chart and calculate the total cost for this alternative.

(d) Assume that 400 minutes are available per day, and parts completed by each machine are sent to an assembly station in which the final assembly will be done. How many finished products can be completed per day?

Loading (min.) Processing (min.) M/C Idle Cost ($/hour) Operator Cost: $7/hr Machine A B 2 4 4 6 2 3 3 4 4Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts