Question: To achieve higher efficiency (lower unit costs), managers typically select the type of process they use (job, batch, assembly line or flow) based on expected

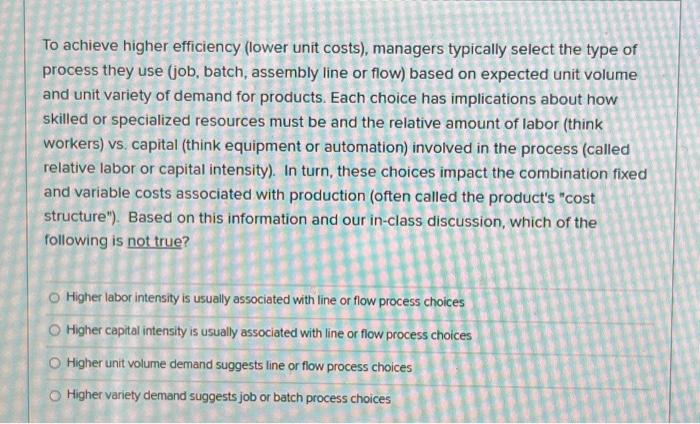

To achieve higher efficiency (lower unit costs), managers typically select the type of process they use (job, batch, assembly line or flow) based on expected unit volume and unit variety of demand for products. Each choice has implications about how skilled or specialized resources must be and the relative amount of labor (think workers) vs. capital (think equipment or automation) involved in the process (called relative labor or capital intensity). In turn, these choices impact the combination fixed and variable costs associated with production (often called the product's "cost structure"). Based on this information and our in-class discussion, which of the following is not true? Higher labor intensity is usually associated with line or flow process choices Higher capital intensity is usually associated with line or flow process choices Higher unit volume demand suggests line or flow process choices Higher variety demand suggests job or batch process choices

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts