Question: Toshiba's Notebook Computer Assembly Line Toshihiro Nakamura, manufacturing engineering section manager, is examining the prototype assembly process sheet ( shown in Exhibit 6 . 8

Toshiba's Notebook Computer Assembly Line

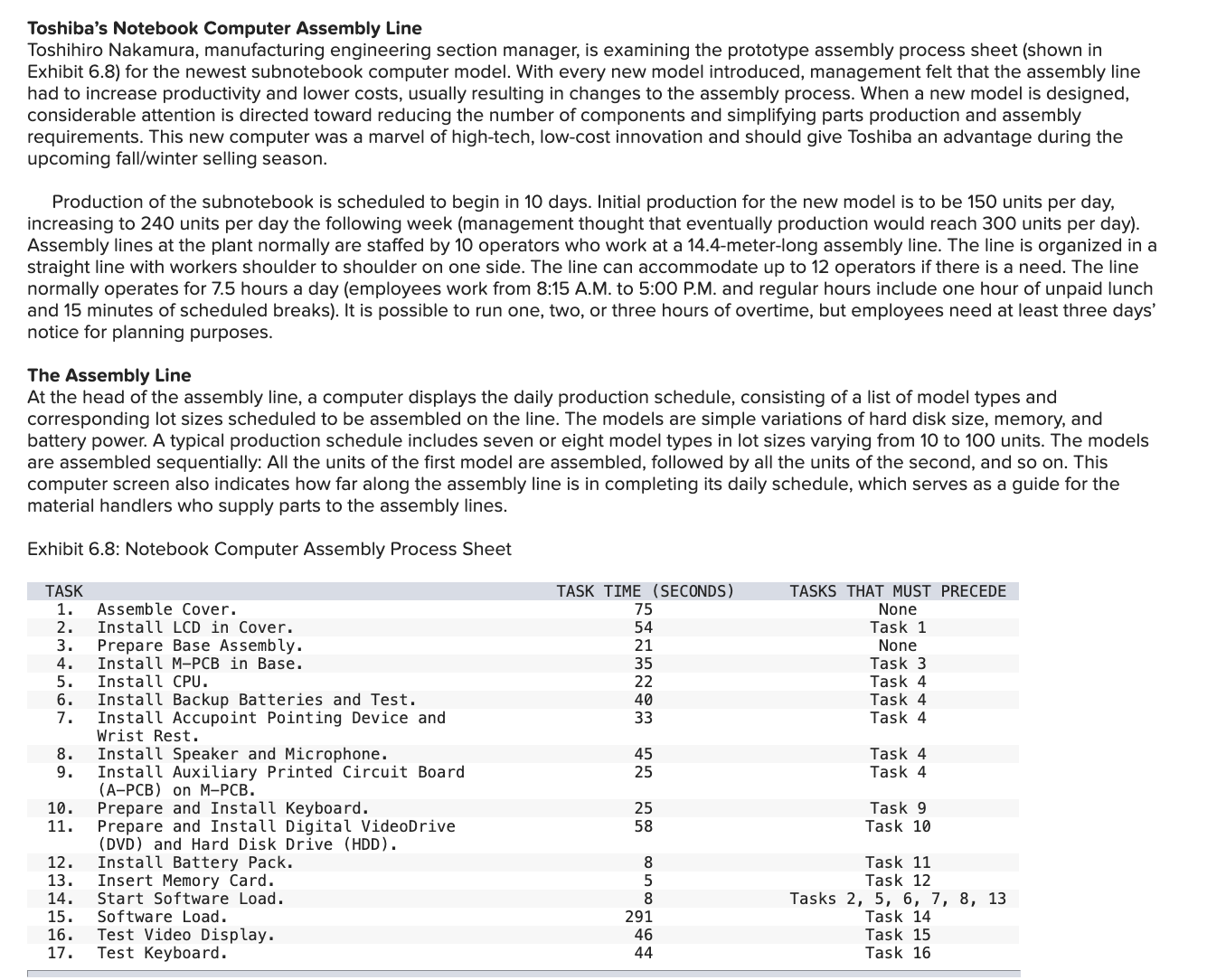

Toshihiro Nakamura, manufacturing engineering section manager, is examining the prototype assembly process sheet shown in Exhibit for the newest subnotebook computer model. With every new model introduced, management felt that the assembly line had to increase productivity and lower costs, usually resulting in changes to the assembly process. When a new model is designed, considerable attention is directed toward reducing the number of components and simplifying parts production and assembly requirements. This new computer was a marvel of hightech, lowcost innovation and should give Toshiba an advantage during the upcoming fallwinter selling season.

Production of the subnotebook is scheduled to begin in days. Initial production for the new model is to be units per day, increasing to units per day the following week management thought that eventually production would reach units per day Assembly lines at the plant normally are staffed by operators who work at a meterlong assembly line. The line is organized in a straight line with workers shoulder to shoulder on one side. The line can accommodate up to operators if there is a need. The line normally operates for hours a day employees work from : AM to : PM and regular hours include one hour of unpaid lunch and minutes of scheduled breaks It is possible to run one, two, or three hours of overtime, but employees need at least three days' notice for planning purposes.

The Assembly Line

At the head of the assembly line, a computer displays the daily production schedule, consisting of a list of model types and corresponding lot sizes scheduled to be assembled on the line. The models are simple variations of hard disk size, memory, and battery power. A typical production schedule includes seven or eight model types in lot sizes varying from to units. The models are assembled sequentially: All the units of the first model are assembled, followed by all the units of the second, and so on This computer screen also indicates how far along the assembly line is in completing its daily schedule, which serves as a guide for the material handlers who supply parts to the assembly lines.

Exhibit : Notebook Computer Assembly Process Sheet

begintabularcccc

hline TASK & & TASK TIME SECONDS & TASKS THAT MUST PRECEDE

hline & Assemble Cover. & & None

hline & Install LCD in Cover. & & Task

hline & Prepare Base Assembly. & & None

hline & Install MPCB in Base. & & Task

hline & Install CPU. & & Task

hline & Install Backup Batteries and Test. & & Task

hline & Install Accupoint Pointing Device and Wrist Rest. & & Task

hline & Install Speaker and Microphone. & & Task

hline & Install Auxiliary Printed Circuit Board APCB on MPCB & & Task

hline & Prepare and Install Keyboard. & & Task

hline & Prepare and Install Digital VideoDrive DVD and Hard Disk Drive HDD & & Task

hline & Install Battery Pack. & & Task

hline & Insert Memory Card. & & Task

hline & Start Software Load. & & Tasks

hline & Software Load. & & Task

hline & Test Video Display. & & Task

hline & Test Keyboard. & & Task

hline

endtabular The daily schedules are shared with the nearby Fujihashi Parts Collection and Distribution Center. Parts are brought from Fujihashi to the plant within two hours of when they are needed. The material supply system is very tightly coordinated and works well.

The assembly line consists of a meter conveyor belt that carries the computers, separated at meter intervals by white stripes on the belt. Workers stand shoulder to shoulder on one side of the conveyor and work on the units as they move by In addition to the assembly workers, a highly skilled worker, called a "supporter," is assigned to each line. The supporter moves along the line, assisting workers who are falling behind and replacing workers who need to take a break. Supporters also make decisions about what to do when problems are encountered during the assembly process such as a defective part The line speed and the number of workers vary from day to day, depending on production demand and the workers' skills and availability. Although the assembly line has positions, often they are not all used.

Exhibit provides details of how the engineers who designed the new subnotebook computer felt that the new line should be organized.

Exhibit : Engineers' initial design of the assembly line

begintabularcccc

hline begintabularl

ASSEMBLY

LINE POSITION

endtabular & TASKS & WORKSTATION NUMBER & LABOR TIME SECONDS

hline & Assemble Cover. & &

hline & Install LCD in cover. & &

hline & P

Empty.

In words, the follo

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock