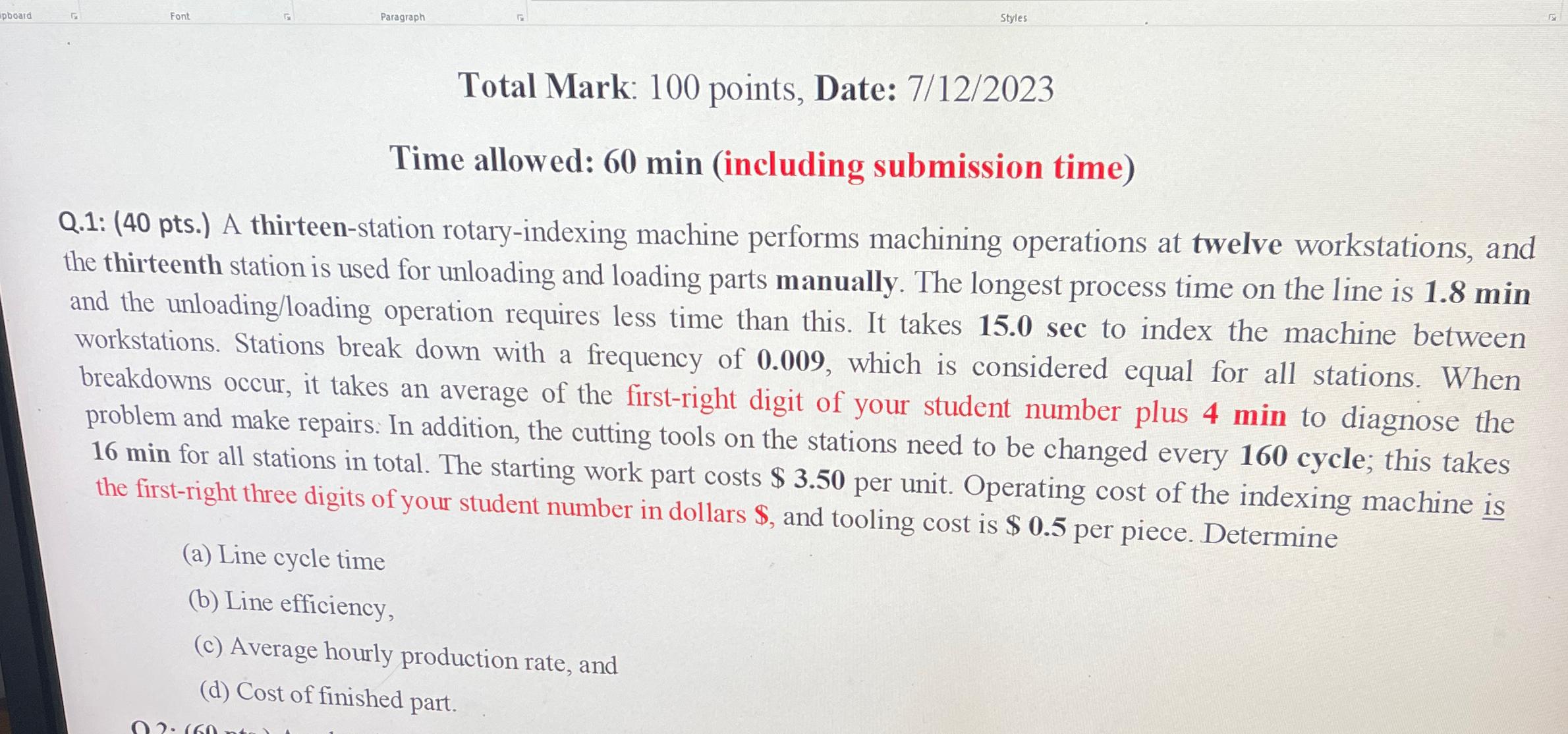

Question: Total Mark: 1 0 0 points, Date: 7 / 1 2 / 2 0 2 3 Time allowed: 6 0 min ( including submission time

Total Mark: points, Date:

Time allowed: min including submission time

Q: pts A thirteenstation rotaryindexing machine performs machining operations at twelve workstations, and the thirteenth station is used for unloading and loading parts manually. The longest process time on the line is min and the unloadingloading operation requires less time than this. It takes to index the machine between workstations. Stations break down with a frequency of which is considered equal for all stations. When breakdowns occur, it takes an average of the firstright digit of your student number plus min to diagnose the problem and make repairs. In addition, the cutting tools on the stations need to be changed every cycle; this takes min for all stations in total. The starting work part costs $ per unit. Operating cost of the indexing machine is the firstright three digits of your student number in dollars $ and tooling cost is $ per piece. Determine

a Line cycle time

b Line efficiency,

c Average hourly production rate, and

d Cost of finished part.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock