Question: Total Productive maintenance is a technique that can be used by a company to achieve a world - class standard of performance in terms of

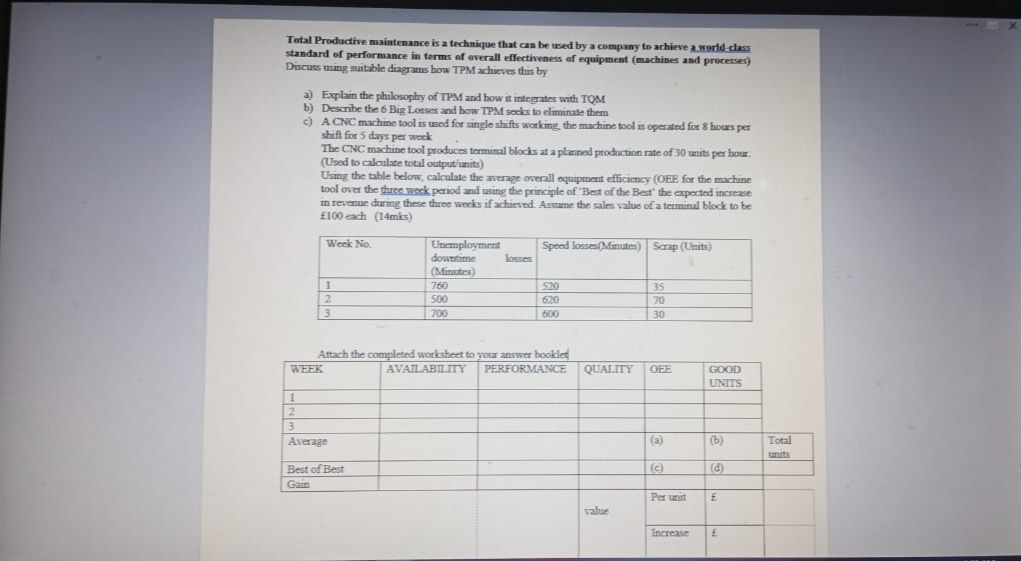

Total Productive maintenance is a technique that can be used by a company to achieve a worldclass standard of performance in terms of overall effectiveness of equipment machines and processes Discuss using suitable diagrams how TPM achieves this by a Explain the philosophy of TPM and how it integrates with TQM b Describe the Big Losses and how TPM seeks to eliminate them c A CNC machine tool is used for single shifts working, the machine tool is operated for hours per shift for days per week The CNC machine tool produces terminal blocks at a planned production rate of units per hour. Used to calculate total outputunits Using the table below, calculate the average overall equipment efficiency OEE for the machine tool over the three week period and using the principle of Best of the Best the expected increase in revenue during these three weeks if achieved. Assume the sales value of a terminal block to be eachmks Total Productive maintenance is a technique that can be used by a company to achieve anortdclass standard of performance in terms of overall effectiveness of equipment machines and processes Discuss using suitable diagrams how TPM achieves this by a Explain the philosophy of TPM and how it integrates with TQM b Describe the Big Losses and how TPM seeks to eliminate them c A CNC machine tool is used for single shifts working, the machine tool is operatod for hours per shift for days per week The CNC machine tool produces terminal blocks at a planned production rate of units per hour. Used to calculate total outputiunits Using the table below, calculate the average overall equipment efficiency OEE for the machine tool over the three week period and using the principle of 'Best of the Best' the expected increase in reverne during these three weeks if achieved. Asrume the sales value of a terminal block to be each mks begintabularllllhline Week No & Unemployment downtime losses Minutes & Speed lossesMmutes & Scrap Unitshline & & & hline & & & hline & & & hline endtabular Attach the completed worksheet to your answer booklet begintabularlllllllhline WEEK & AVAII ABII.ITY & PERFORMANCE & QUALITY & OEE & GOOD UNITS & multirowhline & & & & & & hline & & & & & & hline & & & & & & hline Average & & & & a & b & Total units hline Best of Best & & & & c & d & hline Gain & & & & & & hline multirow & multirow & multirow & multirowvalue & multicolumnc & hline & & & & Increase & & hline endtabular

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock