Question: trojan technologies please answer 1)alternatives 2)decision criteria 3) recommendations 4) implementation plan i only need these 4 things Trojan Technologies As Joyce Guo, senior buyer

trojan technologies

please answer

1)alternatives

2)decision criteria

3) recommendations

4) implementation plan

i only need these 4 things

Trojan Technologies

As Joyce Guo, senior buyer at Trojan Technologies Inc. in London, Ontario, Canada, finished her presentation, Randy Haill, materials manager, made the following com- ments to her:

It appears there is a lot of opportunity and I want to proceed to the next step. Joyce, I need you to lay out an implementation plan for low-cost region sourcing that we can take to the president for his approval. Our plan will have to include the sourcing process, a schedule and timeline for implementation, a budget and the expected savings. We will also have to identify the risks and our contingency plans. Get to work on this and lets meet Friday morning next week to follow-up.

It was Thursday, February 23 and, as Joyce packed up her laptop and notes, she recognized that she had a lot more work to do before her meeting with Randy the fol- lowing week.

TROJAN TECHNOLOGIES

Trojan Technologies Inc. (Trojan) was a leading water treatment technology company with the largest installed base of ultraviolet water treatment systems in operation around the world. Trojan specialized in the design, manu- facture, and sale of pressurized and open-channel, ultra- violet disinfection and water treatment systems for indus- trial, municipal, commercial, and residential applications. Trojans head office was in London, Ontario, Canada. The company had sales of $140 million and employed approxi- mately 400 people in offices around the world, and served its customer base through an extensive network of dealers and representatives.

Trojan was owned by Danaher Corporation (Danaher), which had acquired the company in 2004. Danaher was a diversified global manufacturer, with businesses in pro- fessional instrumentation, industrial technologies, and tools and components. Sales revenues were $6.8 billion with a net profit of $746 million, and Danaher employed approximately 37,000 people. Management used its Da- naher Business System (DBS) of continuous improve- ment to guide and measure operations and business ac- tivities.

Trojans current product line consisted of 10 systems across its five markets: (1) residential water treatment, (2) municipal drinking water, (3) municipal wastewater,

(4) environmental contaminant treatment, and (5) indus- trial process. Systems for commercial and government cus- tomers ranged from approximately $50,000 to more than $1 million. These systems, which typically had a product life cycle of 7 to 10 years before being replaced with a new design, were designed and manufactured at the London facility, and modified to meet individual customer require- ments. In a typical year, Trojan manufactured 500 to 600 sys- tems for its commercial and government customers.

THE PURCHASING ORGANIZATION

Trojans purchasing organization had seven buyers re- sponsible for six commodity groups:

1. Lamps, quartz sleeves, and ballast. 2. Electrical parts and panels.

3. Stainless steel fabrication parts.

4. Machined and plastic parts.

5. Hydraulic parts and sensors. 6. MRO.

Purchases in the first two commodity groups accounted for approximately 60 percent of Trojans $45 million spend on direct materials. However, most of these compo- nents were high-technology items and were locked up in strategic sourcing agreements. The remaining 40 percent comprised approximately 400 SKUs that were sourced pri- marily to North American suppliers.

THE LOW-COST REGION SOURCING PROJECT

Following its acquisition of Trojan, Danaher implemented several new initiatives aimed at improving corporate per- formance. One area targeted was global sourcingan ini- tiative Randy was asked to champion.

Randy turned to Joyce to lead a project investigating potential opportunities at Trojan for global sourcing and to recommend what action, if any, the company should take. Joyce had joined Trojan, approximately one year prior fol- lowing completion of her MBA at the Richard Ivey School of Business, as senior buyer for stainless steel fabrication parts. With her background as a purchasing manager for a state-owned enterprise in China before returning to school at Ivey, Randy felt that Joyce had the perfect credentials to lead the low-cost region sourcing project.

In her report to Randy on February 23, Joyce indicated that

Trojans global sourcing was not part of the com- panys purchasing strategy. Presently, international purchases were limited only to those components that were otherwise not available to North America.

By not engaging in global sourcing, Trojan was miss- ing potential opportunities for lower costs, higher quality, and improved product availability.

Companies using global sourcing had been able to reduce costs substantially for some products and services.

Several Danaher businesses sourced components globally and the company had set up an international purchasing office in China, staffed by five people: a sourcing manager, a buyer, and three engineers.

China appeared to offer Trojan the best opportunities for low-cost sourcing, and Joyce suggested that the company start its global sourcing initiative there.

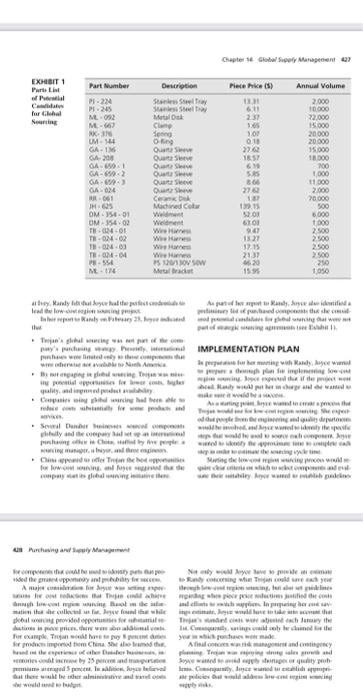

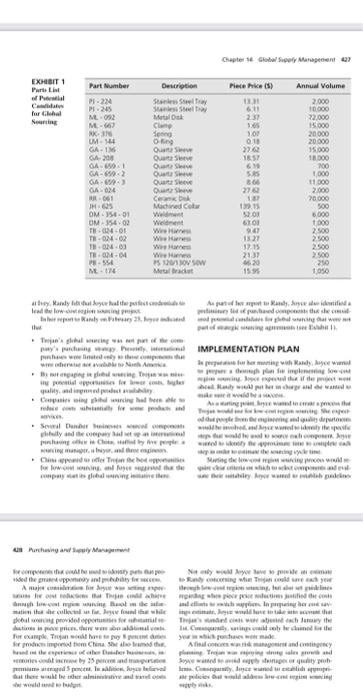

As part of her report to Randy, Joyce also identified a preliminary list of purchased components that she consid- ered potential candidates for global sourcing that were not part of strategic sourcing agreements (see Exhibit 1).

IMPLEMENTATION PLAN

In preparation for her meeting with Randy, Joyce wanted to prepare a thorough plan for implementing low-cost region sourcing. Joyce expected that if the project went ahead, Randy would put her in charge and she wanted to make sure it would be a success.

As a starting point, Joyce wanted to create a process that Trojan would use for low-cost region sourcing. She expect- ed that people from the engineering and quality departments would be involved, and Joyce wanted to identify the specific steps that would be used to source each component. Joyce wanted to identify the approximate time to complete each step in order to estimate the sourcing cycle time.

Starting the low-cost region sourcing process would re- quire clear criteria on which to select components and eval- uate their suitability. Joyce wanted to establish guidelines

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock