Question: True or False ( 3 0 points - 2 pts each ) a ) ( T F If the setup costs are dramatically decreased in

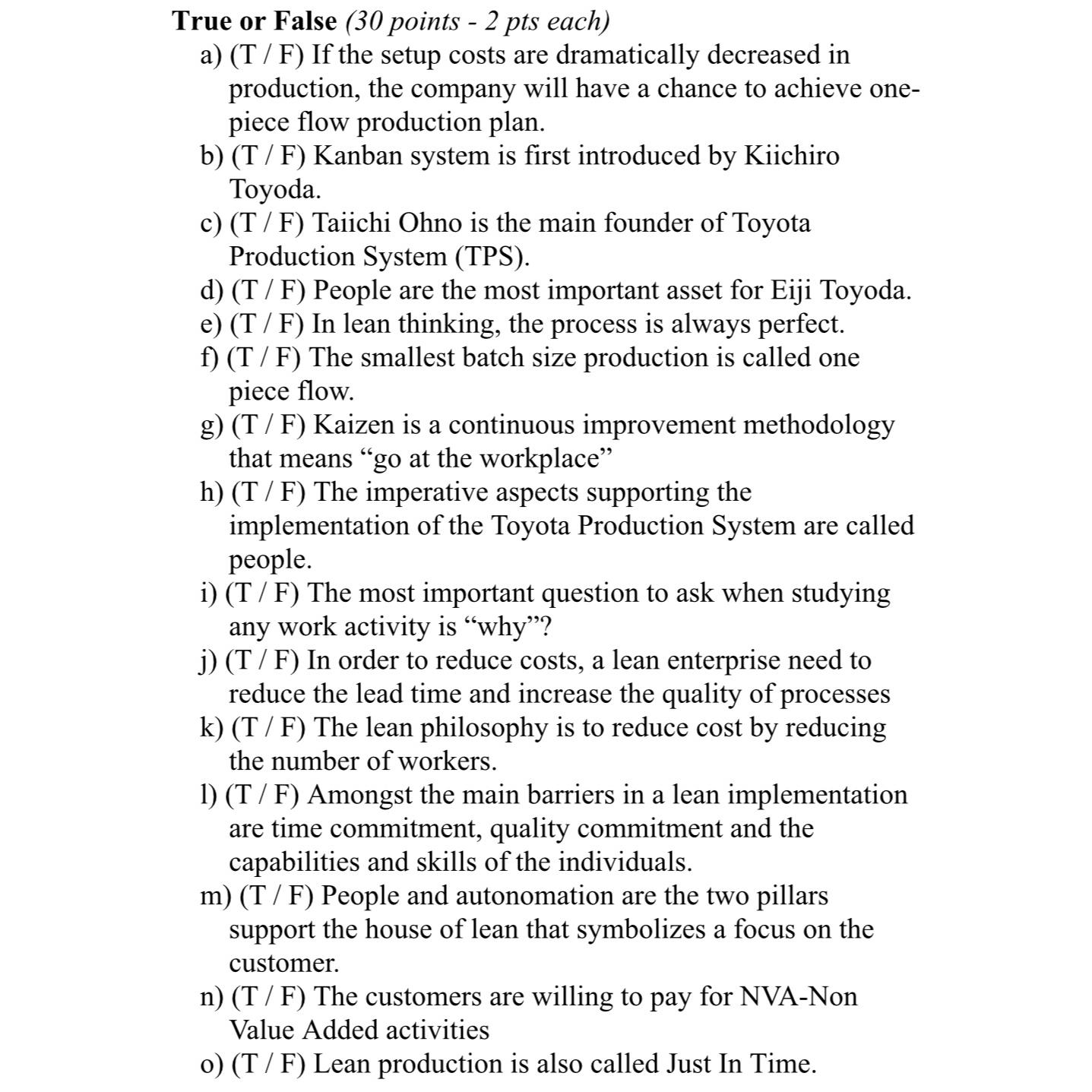

True or False points pts each

a If the setup costs are dramatically decreased in production, the company will have a chance to achieve onepiece flow production plan.

bTF Kanban system is first introduced by Kiichiro Toyoda.

cTF Taiichi Ohno is the main founder of Toyota Production System TPS

dTF People are the most important asset for Eiji Toyoda.

e In lean thinking, the process is always perfect.

fTF The smallest batch size production is called one piece flow.

gTF Kaizen is a continuous improvement methodology that means go at the workplace"

hTF The imperative aspects supporting the implementation of the Toyota Production System are called people.

iTF The most important question to ask when studying any work activity is "why"?

j In order to reduce costs, a lean enterprise need to reduce the lead time and increase the quality of processes

k The lean philosophy is to reduce cost by reducing the number of workers.

F Amongst the main barriers in a lean implementation are time commitment, quality commitment and the capabilities and skills of the individuals.

mTF People and autonomation are the two pillars support the house of lean that symbolizes a focus on the customer.

nTF The customers are willing to pay for NVANon Value Added activities

o Lean production is also called Just In Time.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock