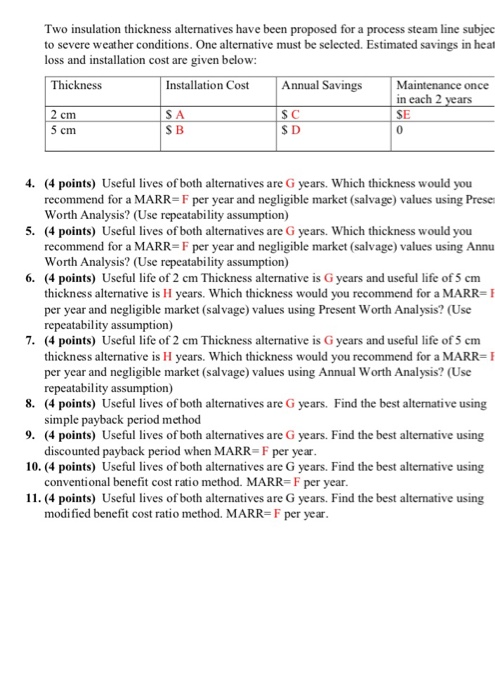

Question: Two insulation thickness alternatives have been proposed for a process steam line subjec to severe weather conditions. One alternative must be selected. Estimated savings in

Two insulation thickness alternatives have been proposed for a process steam line subjec to severe weather conditions. One alternative must be selected. Estimated savings in heat loss and installation cost are given below: Thickness Installation Cost Annual Savings Maintenance once in each 2 years 2 cm SA SE 5 cm SB SC SD 0 4. (4 points) Useful lives of both alternatives are G years. Which thickness would you recommend for a MARR=F per year and negligible market (salvage) values using Prese Worth Analysis? (Use repeatability assumption) 5. (4 points) Useful lives of both alternatives are G years. Which thickness would you recommend for a MARR=F per year and negligible market (salvage) values using Annu Worth Analysis? (Use repeatability assumption) 6. (4 points) Useful life of 2 cm Thickness alternative is G years and useful life of 5 cm thickness alternative is H years. Which thickness would you recommend for a MARR= ! per year and negligible market (salvage) values using Present Worth Analysis? (Use repeatability assumption) 7. (4 points) Useful life of 2 cm Thickness alternative is G years and useful life of 5 cm thickness alternative is H years. Which thickness would you recommend for a MARR=1 per year and negligible market (salvage) values using Annual Worth Analysis? (Use repeatability assumption) 8. (4 points) Useful lives of both alternatives are G years. Find the best alternative using simple payback period method 9. (4 points) Useful lives of both alternatives are G years. Find the best alternative using discounted payback period when MARR=F per year. 10.(4 points) Useful lives of both alternatives are G years. Find the best alternative using conventional benefit cost ratio method. MARR=F per year. 11. (4 points) Useful lives of both alternatives are G years. Find the best alternative using modified benefit cost ratio method. MARR=F per year. Two insulation thickness alternatives have been proposed for a process steam line subjec to severe weather conditions. One alternative must be selected. Estimated savings in heat loss and installation cost are given below: Thickness Installation Cost Annual Savings Maintenance once in each 2 years 2 cm SA SE 5 cm SB SC SD 0 4. (4 points) Useful lives of both alternatives are G years. Which thickness would you recommend for a MARR=F per year and negligible market (salvage) values using Prese Worth Analysis? (Use repeatability assumption) 5. (4 points) Useful lives of both alternatives are G years. Which thickness would you recommend for a MARR=F per year and negligible market (salvage) values using Annu Worth Analysis? (Use repeatability assumption) 6. (4 points) Useful life of 2 cm Thickness alternative is G years and useful life of 5 cm thickness alternative is H years. Which thickness would you recommend for a MARR= ! per year and negligible market (salvage) values using Present Worth Analysis? (Use repeatability assumption) 7. (4 points) Useful life of 2 cm Thickness alternative is G years and useful life of 5 cm thickness alternative is H years. Which thickness would you recommend for a MARR=1 per year and negligible market (salvage) values using Annual Worth Analysis? (Use repeatability assumption) 8. (4 points) Useful lives of both alternatives are G years. Find the best alternative using simple payback period method 9. (4 points) Useful lives of both alternatives are G years. Find the best alternative using discounted payback period when MARR=F per year. 10.(4 points) Useful lives of both alternatives are G years. Find the best alternative using conventional benefit cost ratio method. MARR=F per year. 11. (4 points) Useful lives of both alternatives are G years. Find the best alternative using modified benefit cost ratio method. MARR=F per year

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts