Question: Two major themes from the introduction to module 4 are Project Management and Managing Risk. Discuss, in depth, your analysis of the company's actions in

Two major themes from the introduction to module 4 are "Project Management" and

"Managing Risk." Discuss, in depth, your analysis of the company's actions in relation to

the concepts of these two major themes. You must discuss these in much more detail and

to a broader degree than the discussion of Boeing in the introduction material for these

themes.

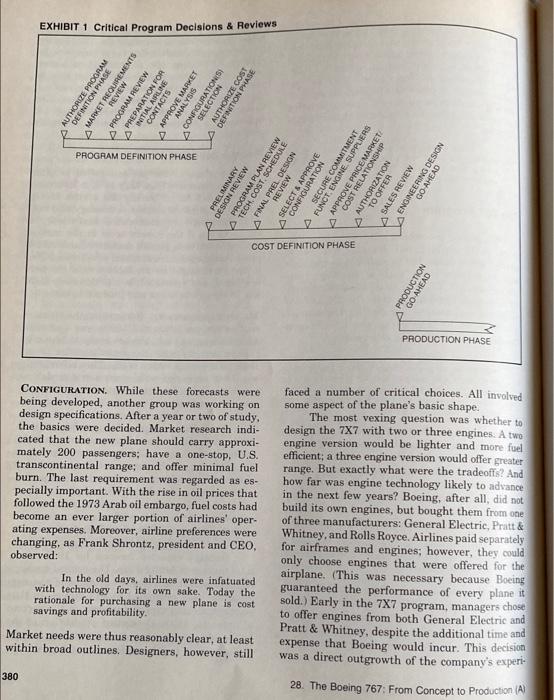

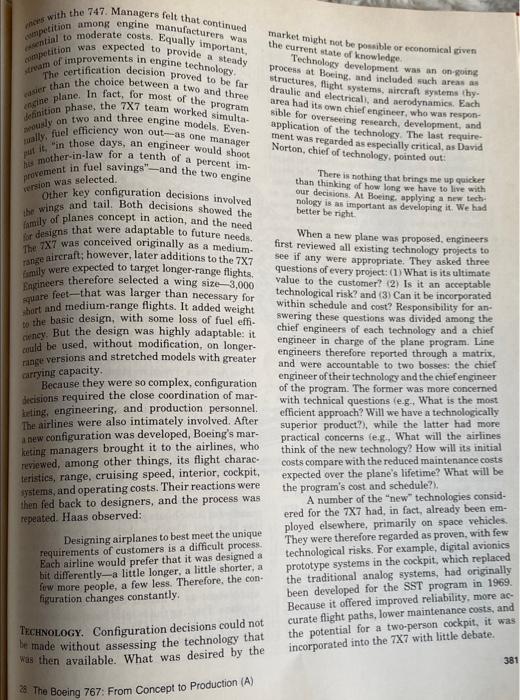

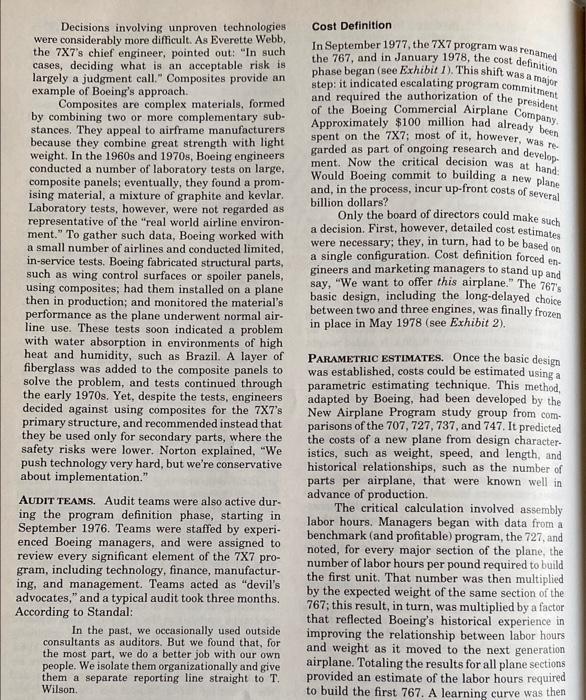

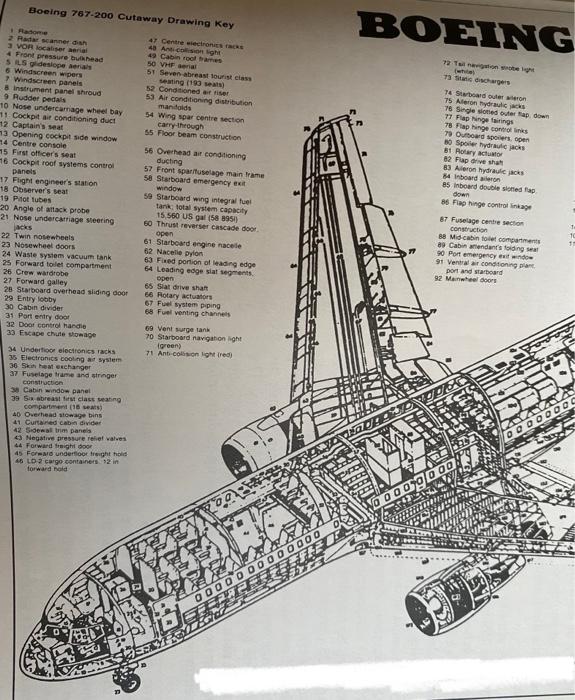

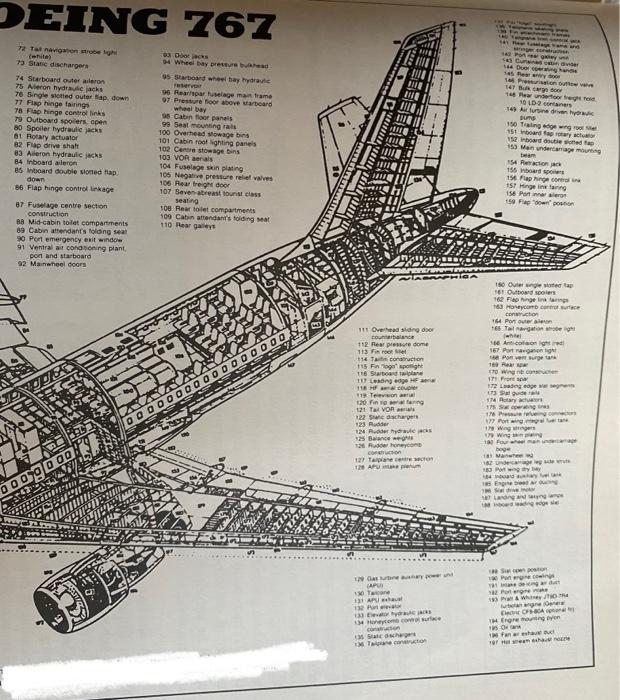

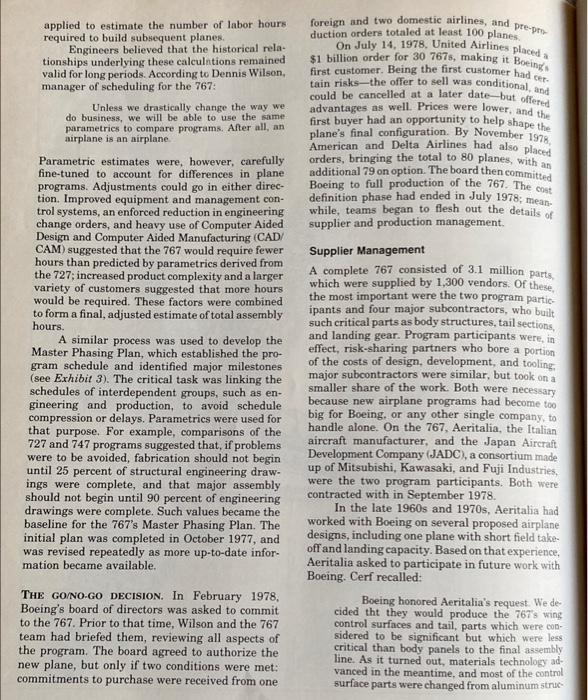

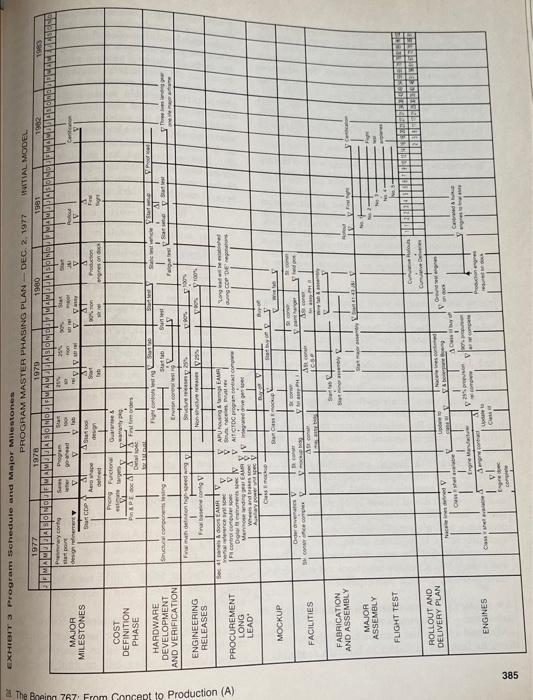

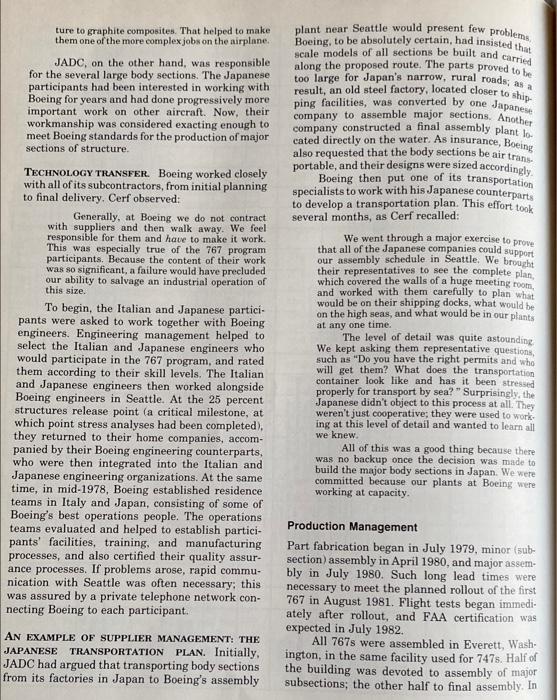

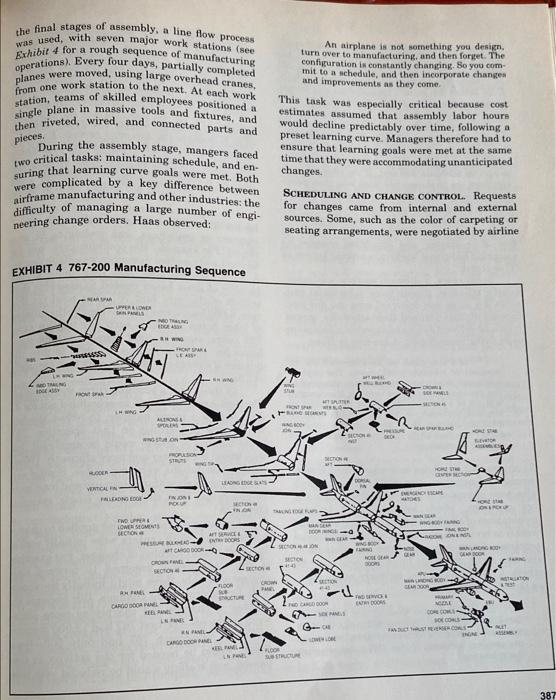

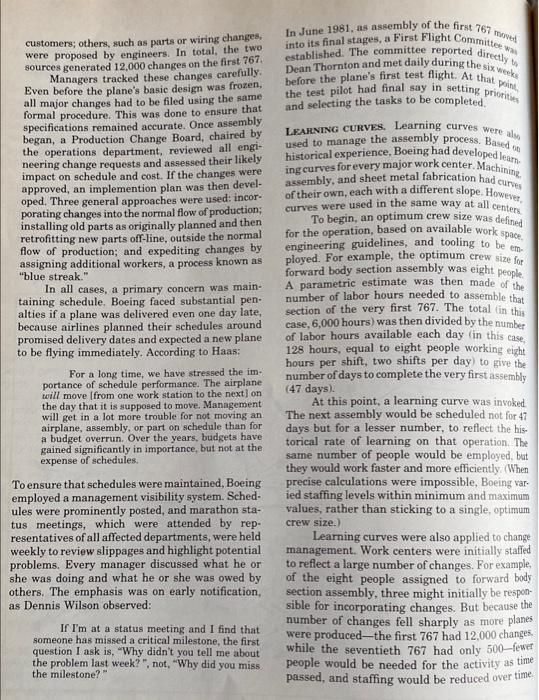

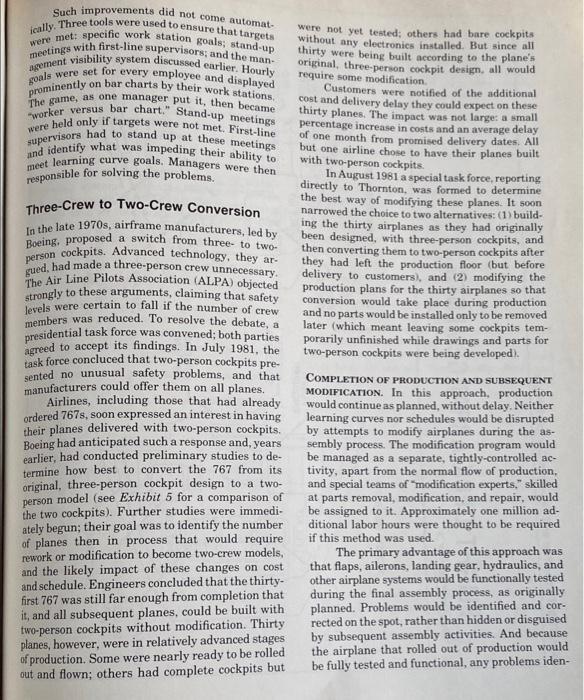

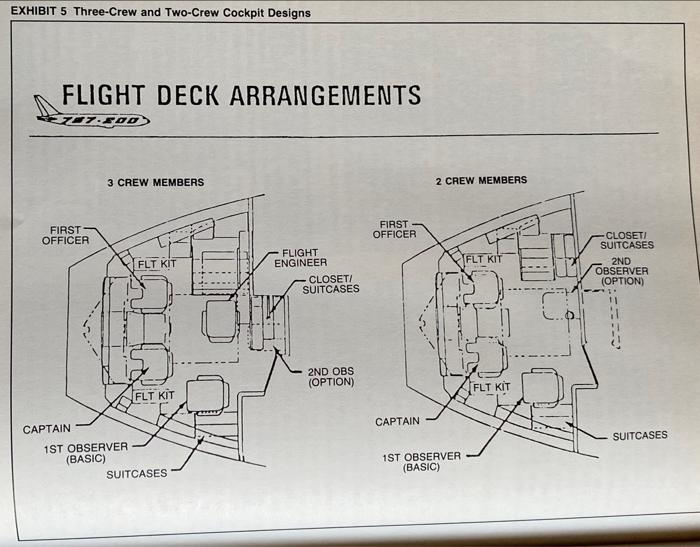

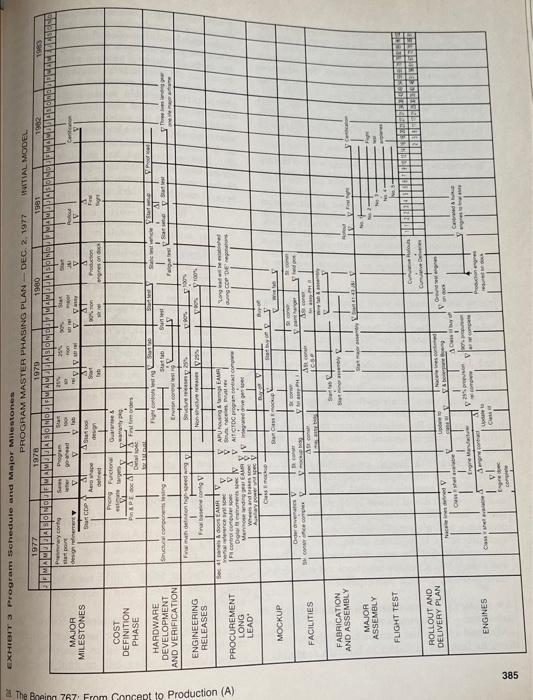

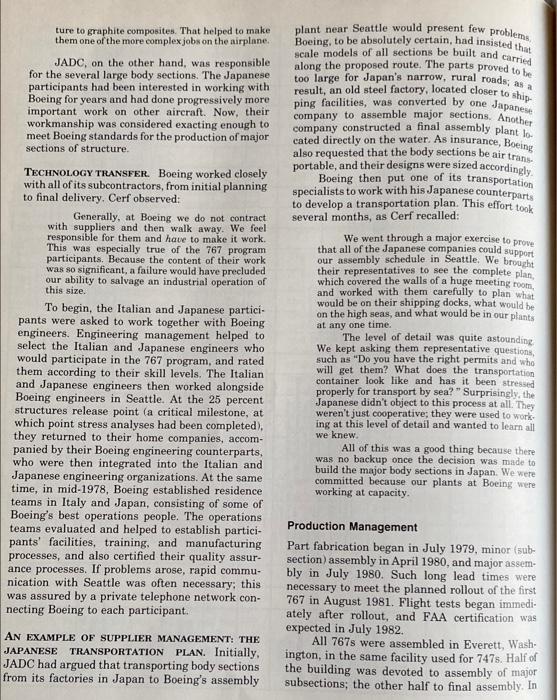

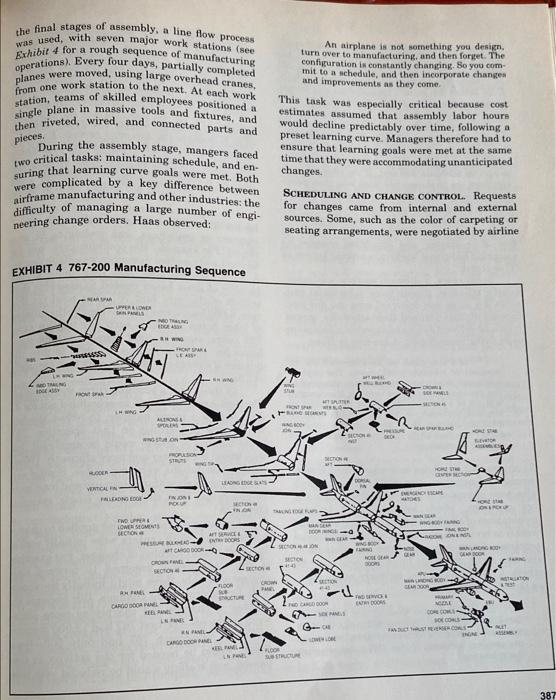

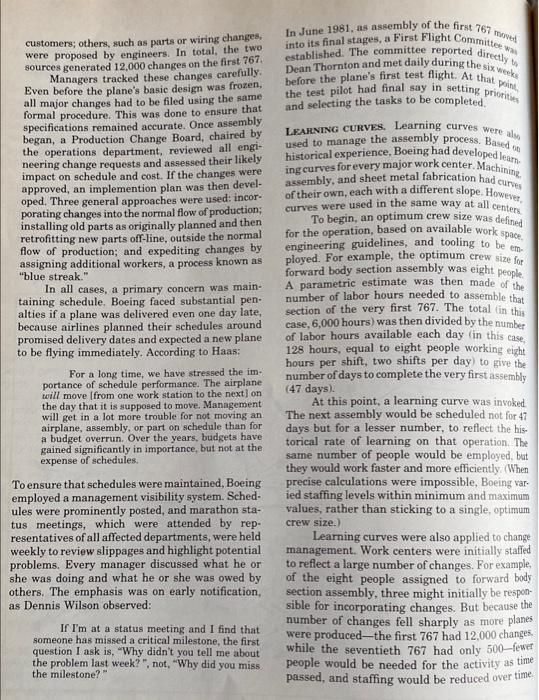

28. The Boeing 767: From Concept to Production (A) In August 1981, eleven months before the first scheduled delivery of Boeing's new airplane, the 767, Dean Thorn- ton, the program's vice president-general manager, faced a critical decision. For several years, Boeing had lobbied the Federal Aviation Administration (FAA) for permission to build wide-bodied aircraft with two- rather than three-person cockpits. Permission had been granted late in July. Unfortunately, the 767 had orig. inally been designed with a three-person cockpit, and 30 of those planes were already in various stages of production. Thornton knew that the planes had to be con- verted to models with two person cockpits. But what was the best way to proceed? Should the changes be made in-line, inserting new cockpits into the 30 planes without removing them from the flow of production, or off-line, building the 30 planes with three-person cock- pits as originally planned and then retrofitting them i with two-person cockpits in a separate rework area? Either way, Thornton knew that a decision had to be made quickly. Promised delivery dates were sacred at Boeing, and the changes in cockpit design might well impose substantial delays. The Airframe Industry Commercial aircraft manufacturing was an in- dustry of vast scale and complexity. A typical 767 contained 3.1 million individual parts; federal regulations required that many be documented and traceable. There were 85 miles of wiring An airframe is an airplane without engines. Technically, Boeing competed in the airframe industry. In this case, however, the terms airframe, airplane, and aircraft are used interchangeably. 376 alone. Manufacturers employed thousands of sci- entists and engineers to develop new technologies and production systems, and also to attack design problems. Facilities were on a similarly grand scale. Boeing assembled the 747, its largest com mercial airplane, in the world's largest building- 62 acres under a single roof-with a work force of 28,600 people. Few companies were able to marshal such massive resources. In 1981 the industry had only three major players: the American manufacturers, Boeing and McDonnell Douglas, and the European consortium, Airbus. A fourth manufacturer, Lock- heed, left the commercial airplane industry in 1981 after its wide-bodied jet, the L-1011, had incurred losses of $2.5 billion. Boeing and Me Donnell Douglas were competitors of longstand- ing, Airbus, on the other hand, made its commercial debut in May 1974. It was not generally regarded as a serious competitive threat until 1978, the date of its first large sale to a U.S. airline. By 1981, Airbus has sold 300 planes to 41 airlines, and had options for 200 more. It received direct financing and subsidies from the French, Spanish, German, and British governments. Airframe manufacturing was a business of enormous risks, for in no other industry was so much capital deployed with so much uncertainty. Launching a new plane meant up-front develop- ment costs of $1.5-2 billion, lead times of up to four years from Go-ahead to first delivery, and the qualification and management of thousands of subcontractors. Projects of this scale could put a company's entire net worth on the line. For that reason, industry executives were sometimes characterized as "gamblers," sporting participants in a high- 28. The Boeing 767: From Concept to Production (A stakes game. Side bets-actual wagers between manufacturers and airlines regarding airplane performance, features, or delivery dates-occa- sionally accompanied purchase negotiations. The odds against a successful new product were large. According to one industry expert, in the past thirty years only two new plane programs, the Boeing 707 and 727, actually made money. (Ac- cording to Boeing, the 737 and 747 programs have also been profitable.) If a new program were successful, however, the potential returns were enormous. A successful new plane could lock up its chosen market segment for as long as 20 years, producing sales of $25-45 billion and huge profits. It was also likely to bring great prestige, power, and influence to the company and managers that created it. Success required a long-term view. Compet- itive pricing was essential. Pricing practices, how- ever, contributed risks of their own. New plane prices were based not on the cost of producing the first airplane, but on the average cost of 300 to 400 planes, when required labor hours had de- clined because of learning. This effect, the so- called learning curve, was hardly unique to air- frame manufacturing. But small annual volumes and long manufacturing cycles even during peak periods Boeing planned to build only eight 767s per month-meant that break-even points stretched further into the future in airframe manufacturing than was typical of most other industries, where mass production was the norm. Manufacturers were therefore anxious to build orders for new planes as quickly as possible. Buyers-primarily the 50 leading airlines around the world-used that knowledge to enhance their bargaining positions, often delaying orders until the last possible moment. Negotiations on price, design modifications, and after-sales parts and I service became especially aggressive in the 1970s, when airlines that had been making steady profits began losing large sums of money. Cost savings became a dominant concern. As Richard Ferris, the CEO of United Airlines, remarked: "Don't bug me about interior design or customer preference. just guarantee the seat-mile performance."? John Newhouse, The Sporty Game (New York: Alfred A Knopf, 1982), p. 4. Ibid, page 84. Seat-mile performance is the cost of operating a plane divided by the product of miles flown and the number seats available. 28. The Boeing 767: From Concept to Production (A) The Boeing Company Boeing was the sales leader of the airframe in- dustry, as well as one of America's leading ex- porters. It had built more commercial airplanes than any other company in the world. Sales in 1981 were $9.2 billion; of the total, $5.1 billion were ascribed to the Boeing Commercial Airplane Company, the firm's aircraft manufacturing di- vision. Other divisions produced missiles, rockets, helicopters, space equipment, computers and elec- tronics. HISTORY. The Boeing Company was founded in 1916 by William E. Boeing, the son of a wealthy timber man who had studied engineering at Yale. In its earliest days, the company built military aircraft for use in World War 1. It began prosper in the 1920s and 1930s, when the civil aviation market expanded, primarily because of the de- mand for mail carrying. At about that time, William Boeing issued a challenge that has re- mained the company's credo: Our job is to keep everlastingly at research and experimentation, to adapt our laboratories to production as soon as possible, and to let no new improvement in flying and flying equipment pass us by. To meet this challenge, Boeing originally relied on extensive vertical integration. It not only manufactured entire planes itself, but also pro- vided engines through its Pratt & Whitney sub- sidiary, and bought and flew planes through its United Air Lines subsidiary. A government man- date separated the three entities in 1934. As the costs of developing and producing new aircraft grew ever larger, the company became even more focused. By the late 1970s and early 1980s, Boeing no longer assumed all development costs itself, nor did it fabricate entire airplanes. Instead, it carefully selected partners, some of whom partic- ipated on a risk sharing basis, who were then subcontracted portions of each plane and devel- oped and built parts and subassemblies that Boeing later assembled. The primary exceptions. were the nose section and wings, which Boeing continued to build in-house. One manager sum- marized the situation in the 1970s by saying: "Today Boeing is an assembler who makes wings." In part, such efforts to limit up-front invest- 377 ment and reduce risks were prompted by Boeing's near disastrous experiences with its first wide- bodied jet, the 747. In 1969, when the company was introducing the 737 as well as the 747, management problems, declining productivity, steep development costs and unanticipated prob- lems with the engine, plus cutbacks in commercial and government orders, produced a severe cash crunch. Boeing was close to bankruptcy. In the next three years, the company's work force fell from 150,000 to 50,000; unemployment in Seattle, Boeing's home base, rose to 14 percent. Eventually, such belt tightening, plus efforts to resolve prob- lems with the 737 and 747 programs, carried the day, and Boeing emerged from the crisis leaner and stronger, but with a renewed sense of the inherent risks of major development programs. STRATEGY. Ever since the 707 was introduced in 1955, Boeing had competed by selling families of planes. Each new generation of aircraft was created with several variations in mind, drawing on the same base airframe concept. By 1987 the 747, for example, was being offered in eleven varieties, including the 747-100B (standard), 747- 200B (long range), 747F (freighter), and 747C (convertible to either passenger or cargo config- urations). Flexible designs with inherent growth potential were essential to this approach. Modi- fications such as a stretched fuselage to increase capacity had to be accommodated without whole- sale revisions in design or the need to startup entirely separate development programs. A more efficient design and development process was only one benefit of the family of planes concept. There were manufacturing bene- fits as well. A common family of planes, produced on a common assembly line, ensured that learning was not lost as new models were added. Experi- ence accumulated rapidly, as Thornton observed: We're good partly because we build lots of airplanes. And each new plane absorbs everything we have learned from earlier models. One result of this approach was break-even points that were reached far earlier than they would have been without shared designs. Other cornerstones of Boeing's strategy were expertise in global marketing, technological lead- ership, customer support, and production skills. Large centralized facilities were coupled with 378 sophisticated manufacturing systems and tools for project management. The result, according to informed observers, was the industry's low cost producer. Or as one aerospace analyst summa rized the company's reputation: "If someone hired me to rebuild the Great Pyramid, I'd ask Boeing to assemble it." CULTURE. Boeing managers believed that the company had a distinct corporate identity. Team- work was especially valued, as was interfunctional cooperation. According to Dexter Haas, a manager in corporate planning: At Boeing, employees are expected to be both competent and capable of working as mem bers of a team. We feel that technically brilliant but uncooperative individuals can do as much harm to a program as cooperative but mediocre team members. Such concerns were especially acute on new plane programs, which were a prime vehicle for man- agement development. Programs required close cooperation among managers for five to ten years, often under intense time pressures and 60-70 hour work weeks. To make these programs work, Thornton commented, "You don't necessarily se lect the best people; you select the best team." Once selected, teams were granted consid- erable autonomy. But a disciplined decision-mak- ing process was expected, as was detailed planning. Both were viewed by managers as characteristic Boeing traits. According to Fred Cerf, director of systems and equipment: A part of Boeing's culture is absolute dedi- cation to commitments from individuals within the company and from suppliers. We expect people to honor their commitments and adhere to plans. We don't regard plans as exercises, but as fore- casted events. Meeting schedules was an especially high priority for managers. A variety of tools, several of them unique to Boeing, were used to develop realistic schedules and monitor them over time. Among them were a Master Phasing Plan, which mapped out the entire development cycle, includ- ing critical milestones, for each new plane pro- gram; parametric estimating techniques, which estimated costs and established relationships be Ibid., p. 139. 28. The Boeing 767: From Concept to Production (A) tween critical sections of a schedule, such as the and the start-up of production, by using historical time at which engineering drawings were released data drawn from earlier plane programs; and a management visibility system, which was de- signed to surface problems before they became nication was encouraged, even if it meant bringing serious enough to cause delays. Regular commu- bad news. According to John Schmick, director of planning: Early exposure of problems is not a sin at Boeing. We tend not to kill our managers for taking that approach. Here, it's much worse if you bury the problem. The 767 Program In 1969, Boeing assembled a New Airplane Pro- gram (NAP) study group. Its goal was not to past experiences with each of its major pro- develop a new plane, but to review the company's grams-the 707, 727, 737, and 747-so that prob- lems, such as those incurred by the 737 and 747 programs, would not be repeated. As Neil Standal, a member of the NAP group who later became the 767 program manager, observed: We knew that we were going to have another commercial airplane. But we didn't know what, or when, it was going to be. Our objective was to provide lessons for the future, to look at our history and decide what we had done right and what we had done wrong. This process, called Project Homework, took three years and produced a long list of "lessons learned", as well as a reasonable idea of the costs of developing the next generation airplane. Meanwhile, pressures were beginning to mount within Boeing to launch a new airplane program. Salespeople were especially insistent, as T.A. ("T") Wilson, Boeing's chairman, recalled: Our salespeople kept saying, "We need a new product." They didn't really care what it was, as long as it was new. Because the company's last new plane, the 747, had been launched in 1966, there was also concern among the board of directors that Boeing's next peneration of leaders was not being trained in the best way possible: by developing a new plane of their own. 28 duction (A) In 1973, at Wilson's behest, Boeing initiated a new airplane study, naming it the 7X7 X stood for development model). Key team members, in- cluding J.F. Sutter, the program's first leader, and Dean Thornton, who replaced Sutter after he was promoted to vice president of operations and development, were handpicked by Wilson. The team was given a broad charter: to define and, if approved, to develop, Boeing's next generation airplane. Program Definition The first stage of the process, called program definition, extended from May 1973 to December 1977 (see Exhibit 1). During this period, Boeing worked the puzzle of market, technology, and cost. Team members projected airline needs into the future to see if there were holes in the market not met by existing planes; considered alternative plane configurations, examined new technologies to see what might be available within the next few years; and estimated, in a preliminary fash- ion, likely development and production costs. MARKET ASSESSMENT. Forecasting the airframe market for the 1980s and 1990s was a complex and challenging task. Market analysts began by talking directly with the major airlines to get their estimates of future needs. That information was then combined with econometric models to generate three forecasts-optimistic, conserva- tive, and expected-for each market segment. Segments were defined by range of travel-short (less than 1,500 nautical miles), medium (1,500- 3,000 nautical miles), and long (greater than 3,000 nautical miles)-and all forecasts were based on the following assumptions: continued regulation of the airline industry; continued airline prefer- ences for routes that directly linked pairs of major cities; steadily rising fuel prices; and no new i competition from other airframe manufacturers in the medium range market. Complete forecasts were run annually and readjusted quarterly. Boeing's expected forecast for 1990 was a total market of $100 billion. The critical medium range segment-the expected target of the new airplane-was estimated at $19 billion. In that segment, Boeing expected to capture 100 percent of domestic sales. Continued production of the 727 would meet most replacement needs, and the 7X7 would be positioned for market growth. 379 EXHIBIT 1 Critical Program Decisions & Reviews AUTHORIZE PR MARKET P NOU HASE REVIEWS P PROGRAM REY PREPARATION FOR AL AIRPOR ONTACTS APPROVE MARK ANALYSIS ACONFIGURATI Ma SELECTS) AUTHORIZE PHASE + SON NOULINGE PROGRAM DEFINITION PHASE CONFIGURATION. While these forecasts were being developed, another group was working on design specifications. After a year or two of study, the basics were decided. Market research indi- cated that the new plane should carry approxi- mately 200 passengers; have a one-stop, U.S. transcontinental range; and offer minimal fuel burn. The last requirement was regarded as es- pecially important. With the rise in oil prices that followed the 1973 Arab oil embargo, fuel costs had become an ever larger portion of airlines' oper- ating expenses. Moreover, airline preferences were changing, as Frank Shrontz, president and CEO, observed: In the old days, airlines were infatuated with technology for its own sake. Today the rationale for purchasing a new plane is cost savings and profitability. Market needs were thus reasonably clear, at least within broad outlines. Designers, however, still 380 PROGRAM PLAN RE TECH, COST, SCHEDU DESIGNA FINAL PREL On ain DESIGN IS REVIEW GOING DESI ENGINEERIN GO AHEAD HEDULE DESIGN E SUPPLIERS FUNCT, ENCOMMITMENT FOST RECE MARKET A SECURE. AUTHORIZATION O OFFER SALES RE SELECT & APPROVE CONFIGURATION REVIEW D V COST DEFINITION PHASE PRODUCTION GO AHEAD PRODUCTION PHASE faced a number of critical choices. All involved some aspect of the plane's basic shape. The most vexing question was whether to design the 7X7 with two or three engines. A two engine version would be lighter and more fuel efficient; a three engine version would offer greater range. But exactly what were the tradeoffs? And how far was engine technology likely to advance in the next few years? Boeing, after all, did not build its own engines, but bought them from one of three manufacturers: General Electric, Pratt & Whitney, and Rolls Royce. Airlines paid separately for airframes and engines; however, they could only choose engines that were offered for the airplane. (This was necessary because Boeing guaranteed the performance of every plane it sold.) Early in the 7X7 program, managers chose to offer engines from both General Electric and Pratt & Whitney, despite the additional time and expense that Boeing would incur. This decision was a direct outgrowth of the company's experi- 28. The Boeing 767: From Concept to Production (A) competition among engine manufacturers was ences with the 747. Managers felt that continued essential to moderate costs. Equally important, competition was expected to provide a steady stream of improvements in engine technology. The certification decision proved to be far easier than the choice between a two and three engine plane. In fact, for most of the program definition phase, the 7X7 team worked simulta- neously on two and three engine models. Even- tually, fuel efficiency won out-as one manager his mother-in-law for a tenth of a percent im- put it, "in those days, an engineer would shoot provement in fuel savings"-and the two engine. version was selected. Other key configuration decisions involved the wings and tail. Both decisions showed the family of planes concept in action, and the need for designs that were adaptable to future needs. The 7X7 was conceived originally as a medium- range aircraft; however, later additions to the 7X7 family were expected to target longer-range flights. Engineers therefore selected a wing size-3,000 square feet-that was larger than necessary for short and medium-range flights. It added weight to the basic design, with some loss of fuel effi- cency. But the design was highly adaptable: it could be used, without modification, on longer- range versions and stretched models with greater carrying capacity. Because they were so complex, configuration decisions required the close coordination of mar- keting, engineering, and production personnel. The airlines were also intimately involved. After a new configuration was developed, Boeing's mar- keting managers brought it to the airlines, who reviewed, among other things, its flight charac- teristics, range, cruising speed, interior, cockpit, systems, and operating costs. Their reactions were then fed back to designers, and the process was repeated. Haas observed: Designing airplanes to best meet the unique requirements of customers is a difficult process. Each airline would prefer that it was designed a bit differently-a little longer, a little shorter, a few more people, a few less. Therefore, the con- figuration changes constantly. TECHNOLOGY. Configuration decisions could not be made without assessing the technology that was then available. What was desired by the 28 The Boeing 767: From Concept to Production (A) market might not be possible or economical given the current state of knowledge. Technology development was an on-going process at Boeing, and included such areas as structures, flight systems, aircraft systems (hy- draulic and electrical), and aerodynamics. Each area had its own chief engineer, who was respon sible for overseeing research, development, and application of the technology. The last require- ment was regarded as especially critical, as David Norton, chief of technology, pointed out: There is nothing that brings me up quicker than thinking of how long we have to live with our decisions. At Boeing, applying a new tech nology is as important as developing it. We had better be right When a new plane was proposed, engineers first reviewed all existing technology projects to see if any were appropriate. They asked three questions of every project: (1) What is its ultimate value to the customer? (2) Is it an acceptable technological risk? and (3) Can it be incorporated within schedule and cost? Responsibility for an swering these questions was divided among the chief engineers of each technology and a chief engineer in charge of the plane program. Line engineers therefore reported through a matrix, and were accountable to two bosses: the chief engineer of their technology and the chief engineer of the program. The former was more concerned with technical questions (e.g., What is the most efficient approach? Will we have a technologically superior product?), while the latter had more practical concerns (e.g., What will the airlines think of the new technology? How will its initial costs compare with the reduced maintenance costs expected over the plane's lifetime? What will be the program's cost and schedule?). A number of the "new" technologies consid- ered for the 7X7 had, in fact, already been em- ployed elsewhere, primarily on space vehicles. They were therefore regarded as proven, with few technological risks. For example, digital avionics prototype systems in the cockpit, which replaced the traditional analog systems, had originally been developed for the SST program in 1969. Because it offered improved reliability, more ac- curate flight paths, lower maintenance costs, and the potential for a two-person cockpit, it was incorporated into the 7X7 with little debate. 381 Decisions involving unproven technologies were considerably more difficult. As Everette Webb, the 7X7's chief engineer, pointed out: "In such cases, deciding what is an acceptable risk is largely a judgment call." Composites provide an example of Boeing's approach.. Composites are complex materials, formed. by combining two or more complementary sub- stances. They appeal to airframe manufacturers. because they combine great strength with light weight. In the 1960s and 1970s, Boeing engineers - conducted a number of laboratory tests on large, composite panels; eventually, they found a prom- ising material, a mixture of graphite and kevlar. Laboratory tests, however, were not regarded as representative of the "real world airline environ- ment." To gather such data, Boeing worked with a small number of airlines and conducted limited, in-service tests. Boeing fabricated structural parts, such as wing control surfaces or spoiler panels, using composites; had them installed on a plane then in production; and monitored the material's performance as the plane underwent normal air- line use. These tests soon indicated a problem with water absorption in environments of high heat and humidity, such as Brazil. A layer of fiberglass was added to the composite panels to solve the problem, and tests continued through the early 1970s. Yet, despite the tests, engineers decided against using composites for the 7X7's primary structure, and recommended instead that they be used only for secondary parts, where the safety risks were lower. Norton explained, "We push technology very hard, but we're conservative about implementation." AUDIT TEAMS. Audit teams were also active dur- ing the program definition phase, starting in September 1976. Teams were staffed by experi- enced Boeing managers, and were assigned to review every significant element of the 7X7 pro- gram, including technology, finance, manufactur- ing, and management. Teams acted as "devil's advocates," and a typical audit took three months. According to Standal: In the past, we occasionally used outside consultants as auditors. But we found tha , for the most part, we do a better job with our own people. We isolate them organizationally and give them a separate reporting line straight to T. Wilson. Cost Definition In September 1977, the 7X7 program was renamed the 767, and in January 1978, the cost definition phase began (see Exhibit 1). This shift was a major step: it indicated escalating program commitment and required the authorization of the president of the Boeing Commercial Airplane Company. Approximately $100 million had already been spent on the 7X7; most of it, however, was re- garded as part of ongoing research and develop. ment. Now the critical decision was at hand: Would Boeing commit to building a new plane and, in the process, incur up-front costs of several billion dollars? Only the board of directors could make such a decision. First, however, detailed cost estimates were necessary; they, in turn, had to be based on a single configuration. Cost definition forced en- gineers and marketing managers to stand up and say, "We want to offer this airplane." The 767's basic design, including the long-delayed choice between two and three engines, was finally frozen in place in May 1978 (see Exhibit 2). PARAMETRIC ESTIMATES. Once the basic design was established, costs could be estimated using a parametric estimating technique. This method, adapted by Boeing, had been developed by the New Airplane Program study group from com- parisons of the 707, 727, 737, and 747. It predicted the costs of a new plane from design character- istics, such as weight, speed, and length, and historical relationships, such as the number of parts per airplane, that were known well in advance of production. The critical calculation involved assembly labor hours. Managers began with data from a benchmark (and profitable) program, the 727, and noted, for every major section of the plane, the number of labor hours per pound required to build the first unit. That number was then multiplied by the expected weight of the same section of the 767; this result, in turn, was multiplied by a factor that reflected Boeing's historical experience in improving the relationship between labor hours. and weight as it moved to the next generation airplane. Totaling the results for all plane sections provided an estimate of the labor hours required. to build the first 767. A learning curve was then Boeing 767-200 Cutaway Drawing Key Radome 2 Radar scanner dish 3 VOR localiser aerial 47 Centre electronics racks 43 Anti-collision light 4 Front pressure bulkhead SILS glideslope aerials 49 Cabin roof trames 50 VHF serial 6 Windscreen wipers 51 Seven-abreast tourist class seating (193 seats) 7 Windscreen panels 52 Conditioned air riser 8 Instrument panel shroud 9 Rudder pedals 53 Air conditioning distribution manifolds 10 Nose undercarriage wheel bay 54 Wing spar centre section carry-through 11 Cockpit air conditioning duct 12 Captain's seat 55 Floor beam construction 13 Opening cockpit side window 14 Centre console 15 First officer's seat 56 Overhead air conditioning ducting 16 Cockpit roof systems control panels 57 Front sparifuselage main trame 58 Starboard emergency exit window 17 Flight engineer's station 18 Observer's seat 19 Pitot tubes 59 Starboard wing integral fuel tank; total system capacity 15,560 US gal (58895) 20 Angle of attack probe 60 Thrust reverser cascade door. 21 Nose undercarriage steering jacks open 22 Twin nosewheels 61 Starboard engine nacele 23 Nosewheel doors 62 Nacelle pylon 24 Waste system vacuum tank 63 Fixed portion of leading edge 25 Forward toilet compartment 64 Leading edge slat segments. 26 Crew wardrobe open 27 Forward galley 65 Slat drive shaft 28 Starboard overhead sliding door 66 Rotary actuators 29 Entry lobby 67 Fuel system piping 30 Cabin divider 68 Fuel venting channels 31 Port entry door 32 Door control handle 69 Vent surge tank 33 Escape chute stowage 70 Starboard navigation light (green) 34 Underfloor electronics racks 71 Ant-collision light (red) 35 Electronics cooling air system 36 Skin heat exchanger 37 Fuselage frame and stringer construction 38 Cabin window panel 39 Sa abreast first class seating compartment (18 seats) 40 Overhead stowage bins 41 Curtained cab cabin divider 42 Sidewal trim panels 43 Negative pressure relief valves 44 Forward freight door 45 Forward underfloor freight hold 46 LD-2 cargo containers 12 in forward hold JA 0000000000000 TH 052 BOEING 72 Tail navigation strobe light (while 73 Static dischargers 74 Starboard outer aeron 75 Aleron hydraulic jacks 76 Single sicted outer tap, down 77 Flap hinge fairings 78 Flap hinge control links 79 Outboard spoilers, open 80 Spoiler hydraulic jacks 81 Rotary actuator 82 Flap drive shatt 83 Aleron hydraulic jacks 84 Inboard aileron 85 inboard double sioned fap down 86 Flap hinge control linkage 87 Fuselage centre section construction 88 Mid-cabin toilet compartments 89 Cabin amendant's folding sear 90 Port emergency exit window 91 Ventral air conditioning plant port and starboard 92 Manwheel doors 0 000 Ta DEING 767 93 72 Tal navigation strobe light (white) Door jacks 04 Wheel bay pressure bulkhead 73 Static dischargers 74 Starboard outer aileron 95 Starboard wheel hay hydraulic reservoir 75 Aleron hydraulic jacks 96 Rear/spar fuselage main frame 97 Pressure foor above starboard 76 Single slotted outer Nap, down 77 Flap hinge fairings wheel bay 78 Flap hinge control links 38 Cabin floor panels 79 Outboard spoilers, open 99 Seat mounting rais 80 Spoiler hydraulic jacks 100 Overhead stowage bins 81 Rotary actuator 101 Cabin roof lighting panels 82 Flap drive shaft 102 Centre stowage bins 103 VOR aerials 83 Aileron hydraulic jacks 84 Inboard aileron 104 Fuselage skin plating 85 Inboard double slotted flap. 105 Negative pressure relief valves down 106 Rear freight door 86 Flap hinge control linkage 107 Seven-abreast tourist class seating 87 Fuselage centre section 108 Rear toilet compartments 109 Cabin attendant's folding seat 110 Rear gaileys construction 88 Mid-cabin toilet compartments 89 Cabin attendant's folding seat 90 Port emergency exit window 91 Ventral air conditioning plant, port and starboard 92 Mainwheel doors 000 0000000 111 Overhead sliding door counterbalance 112 Rear pressure dome 113 Fin root M 114 Ta construction 115 Fin "Togo spotlight 116 Starboard tailplane 117 Leading edge HF 118 HF a couple 119 Television anal 120 Finofaring 121 Tal VOR al 122 Stat dischargers 123 Rudder 124 Rudder hydraulic jacks 125 Balance weight 126 Rudder honeycom construction 127 Talpiane centre secto 128 APU pem 129 Gas e auary power und (APL) 130 Tacone 131 APU sval 132 Putr 133 Elevator hydraujac 134 Honeycomb cool surface construction 135 Stadsch 136 Taipiane construction IM 142 Pos galley un 144 Door operating handle earty door 145 146 Persation outlow valve 147 Bulk cargo door 146 er undertoor eight hold 10 LD-2 containers 149 Aur tursine driven hydraulic sump 150 Traling edge wing roo 151 inboard fap rotary actuator 152 Inboard double sted ap 153 Main undercamage mounting beam 154 Reaction jack 155 Inboard spoilers 156 Flap hinge control in 157 Hinge link fairing 156 Port innar aleron 159 Flap down postion 150 Outer englesed tap 161 Outboard spor 162 Flap hinge link fangs 163 Honeycomb cone surface construction 164 Port outer alon 165 Tal nargation strobe light whe 166 Anti-colonight 167 Pot nagann light e Pon vent surge tank 19 Rea 170 Wing consuction 171 Prosp 172 Leading edge wat segment 173 Sat guide ra 174 Rotary actuar 175 Spring 176 Pressu concors 177 Port wing gala 179 Wing singers 179 Wings plating 190 Four man boge 181 Manwhee 162 Undercange leg side ute 183 Pot wing ayl 1841-ad 15 Engine d during 1S de mo 187 Landing and saying lamp od lead Sit open position 10 Pan engine comings 121 nga d 12 Por engine 183 Pal & Whitney 15 Ocak 16 Fanareshaus auct 17 Hot eam exhau nol lubetan angine Ec CF-8A optional Engre mounting on applied to estimate the number of labor hours - required to build subsequent planes. Engineers believed that the historical rela- tionships underlying these calculations remained. valid for long periods. According to Dennis Wilson, manager of scheduling for the 767: Unless we drastically change the way we do business, we will be able to use the same parametrics to compare programs. After all, an airplane is an airplane. Parametric estimates were, however, carefully fine-tuned to account for differences in plane programs. Adjustments could go in either direc- tion. Improved equipment and management con- trol systems, an enforced reduction in engineering change orders, and heavy use of Computer Aided Design and Computer Aided Manufacturing (CAD/ CAM) suggested that the 767 would require fewer hours than predicted by parametrics derived from the 727; increased product complexity and a larger variety of customers suggested that more hours. would be required. These factors were combined to form a final, adjusted estimate of total assembly hours. A similar process was used to develop the Master Phasing Plan, which established the pro- gram schedule and identified major milestones (see Exhibit 3). The critical task was linking the schedules of interdependent groups, such as en- gineering and production, to avoid schedule compression or delays. Parametrics were used for that purpose. For example, comparisons of the 727 and 747 programs suggested that, if problems were to be avoided, fabrication should not begin until 25 percent of structural engineering draw- ings were complete, and that major assembly should not begin until 90 percent of engineering drawings were complete. Such values became the baseline for the 767's Master Phasing Plan. The initial plan was completed in October 1977, and was revised repeatedly as more up-to-date infor- mation became available. THE GO/NO-GO DECISION. In February 1978, Boeing's board of directors was asked to commit to the 767. Prior to that time, Wilson and the 767 team had briefed them, reviewing all aspects of the program. The board agreed to authorize the new plane, but only if two conditions were met: commitments to purchase were received from one foreign and two domestic airlines, and pre-pro duction orders totaled at least 100 planes. On July 14, 1978, United Airlines placed a $1 billion order for 30 767s, making it Boeing's first customer. Being the first customer had cer- tain risks-the offer to sell was conditional, and could be cancelled at a later date-but offered advantages as well. Prices were lower, and the first buyer had an opportunity to help shape the O plane's final configuration. By November 1978, American and Delta Airlines had also placed orders, bringing the total to 80 planes, with an additional 79 on option. The board then committed Boeing to full production of the 767. The cost definition phase had ended in July 1978; mean- while, teams began to flesh out the details of supplier and production management. Supplier Management A complete 767 consisted of 3.1 million parts, which were supplied by 1,300 vendors. Of these, the most important were the two program partic ipants and four major subcontractors, who built such critical parts as body structures, tail sections, and landing gear. Program participants were, in effect, risk-sharing partners who bore a portion of the costs of design, development, and tooling major subcontractors were similar, but took on a smaller share of the work. Both were necessary because new airplane programs had become too big for Boeing, or any other single company, to handle alone. On the 767, Aeritalia, the Italian aircraft manufacturer, and the Japan Aircraft Development Company (JADC), a consortium made up of Mitsubishi, Kawasaki, and Fuji Industries, were the two program participants. Both were contracted with in September 1978. In the late 1960s and 1970s, Aeritalia had worked with Boeing on several proposed airplane designs, including one plane with short field take- off and landing capacity. Based on that experience, Aeritalia asked to participate in future work with Boeing. Cerf recalled: Boeing honored Aeritalia's request. We de- cided tht they would produce the 767's wing control surfaces and tail, parts which were con- sidered to be significant but which were less critical than body panels to the final assembly line. As it turned out, materials technology ad- vanced in the meantime, and most of the control surface parts were changed from aluminum struc The Boeing 767: From Concept to Production (A) 385 EXHIBIT 3 Program Schedule and Major Milestones PROGRAM MASTER PHASING PLAN DEC. 2, 1977 INITIAL MODEL 1977 1978 1979 1980 1981 1982 SEMAMUJABONDJEMAMEJADONOSEMAMPUASONEIZHAMBJAPONOS PJAUSJAHON-OPMAM-HAPPY Pieminary cor sta po Sais Program Sta 20% 33% Stat Dat Fon j design refinement letter go-ahead 100 NO JU fa Po MAJOR MILESTONES Cent Aero shape o Sa design Productos Find engres on dock Mign Guarantee & COST DEFINITION PHASE Prong Functional este targets, Pin & PE doc Structure components testing HARDWARE DEVELOPMENT AND VERIFICATION ENGINEERING RELEASES Fidelion high-speed wing y Fabase con eference syst spec APU housing & langs EAMR Sus naceles P PROCUREMENT LONG LEAD auments spec VATICTDC program contact comp F control comp Diga Mensending gear Agard drive gespec Wheels a Buy of V Classmockp San Cassmockup! MOCKUP co Onders V conoce complex yay FACILITIES S FABRICATION AND ASSEMBLY Straty MAJOR ASSEMBLY FLIGHT TEST ROLLOUT AND DELIVERY PLAN cines de ENGINES Class anet evaad D CDP Se 41 panels & door EAM A A Casa Desp A First fimm orders for at mal Caves Engredie com Det e Stat fab Fight contest ng Envon corres Structures 25% Non-structures 25 bidg Asco TOLEAVE TH U come ancienung aubu Desudury & Stafab Stab Updat C Astco CAP and sea AND Nacenes con C 19 A betere 5600 A Staty WOLL 500 ISHUNG st Starboy co Starte 500 Fa PROS Bay of by partnerve 100% "Longwe dung COP DIE t.com held A cor 100% PH Fagu & Stale est clea Stars Ay C Cu undang in dock. engres A -11 po Fot No Cated & agresy Proof 17 Three si y contain mane 1983 ture to graphite composites. That helped to make them one of the more complex jobs on the airplane.. JADC, on the other hand, was responsible for the several large body sections. The Japanese participants had been interested in working with Boeing for years and had done progressively more important work on other aircraft. Now, their workmanship was considered exacting enough to meet Boeing standards for the production of major sections of structure. TECHNOLOGY TRANSFER. Boeing worked closely with all of its subcontractors, from initial planning to final delivery. Cerf observed: Generally, at Boeing we do not contract with suppliers and then walk away. We feel responsible for them and have to make it work. This was especially true of the 767 program participants. Because the content of their work was so significant, a failure would have precluded our ability to salvage an industrial operation of this size. To begin, the Italian and Japanese partici- pants were asked to work together with Boeing engineers. Engineering management helped to select the Italian and Japanese engineers who would participate in the 767 program, and rated them according to their skill levels. The Italian and Japanese engineers then worked alongside Boeing engineers in Seattle. At the 25 percent structures release point (a critical milestone, at which point stress analyses had been completed), they returned to home companies, accom- panied by their Boeing engineering counterparts, who were then integrated into the Italian and Japanese engineering organizations. At the same time, in mid-1978, Boeing established residence teams in Italy and Japan, consisting of some of Boeing's best operations people. The operations teams evaluated and helped to establish partici- pants' facilities, training, and manufacturing processes, and also certified their quality assur- ance processes. If problems arose, rapid commu- nication with Seattle was often necessary; this was assured by a private telephone network con- necting Boeing to each participant. AN EXAMPLE OF SUPPLIER MANAGEMENT: THE JAPANESE TRANSPORTATION PLAN. Initially, JADC had argued that transporting body sections from its factories in Japan to Boeing's assembly plant near Seattle would present few problems, Boeing, to be absolutely certain, had insisted that scale models of all sections be built and carried along the proposed route. The parts proved to be too large for Japan's narrow, rural roads, as a result, an old steel factory, located closer to ship ping facilities, was converted by one Japanese company to assemble major sections. Another company constructed a final assembly plant lo cated directly on the water. As insurance, Boeing also requested that the body sections be air trans portable, and their designs were sized accordingly. Boeing then put one of its transportation specialists to work with his Japanese counterparts to develop a transportation plan. This effort took several months, as Cerf recalled: We went through a major exercise to prove that all of the Japanese companies could support our assembly schedule in Seattle. We brought their representatives to see the complete plan, which covered the walls of a huge meeting room, and worked with them carefully to plan what would be on their shipping docks, what would be on the high seas, and what would be in our plants at any one time. The level of detail was quite astounding We kept asking them representative questions, such as "Do you have the right permits and who will get them? What does the transportation container look like and has it been stressed properly for transport by sea?" Surprisingly, the Japanese didn't object to this process at all. They weren't just cooperative; they were used to work ing at this level of detail and wanted to learn all we knew. All of this was a good thing because there was no backup once the decision was made to build the major body sections in Japan. We were committed because our plants at Boeing were working at capacity. Production Management Part fabrication began in July 1979, minor (sub- section) assembly in April 1980, and major assem- bly in July 1980. Such long lead times were necessary to meet the planned rollout of the first 767 in August 1981. Flight tests began immedi- ately after rollout, and FAA certification was expected in July 1982. All 767s were assembled in Everett, Wash- ington, in the same facility used for 747s. Half of the building was devoted to assembly of major i subsections; the other half to final assembly. In the final stages of assembly, a line flow process was used, with seven major work stations (see Exhibit 4 for a rough sequence of manufacturing operations). Every four days, partially completed planes were moved, using large overhead cranes, from one work station to the next. At each work station, teams of skilled employees positioned a single plane in massive tools and fixtures, and then riveted, wired, and connected parts and pieces. During the assembly stage, mangers faced two critical tasks: maintaining schedule, and en- suring that learning curve goals were met. Both were complicated by a key difference between airframe manufacturing and other industries: the difficulty of managing a large number of engi- neering change orders. Haas observed: EXHIBIT 4 767-200 Manufacturing Sequence NEAR SPAR UPPER & LOWER PANELS Trang c LM WING MOTRING GAY 5455 FRONT SPAR RUDER VERTICAL FIN WING FALLEADING EDG EDGE A KH WING ALONS SPOKEM ww-stut On" TWD UPPER LOWEN SEGMENTS SECTION AM FAM CARGO DOOR PANEL LE ASS PROPULSION STRUTS WING! INJON POKUP PRESSUME BULKHEAD CROWN PANEL SECTION REEL PANEL CARGO DOOR LN PAN SHANG KN PANEL CARGO DOOR PANE LEADING EDGE secto NON AFT SERVICE ENTDOORS FLOOR SUB UCTURE KELL PANEL LN PAN SECTION CROW PANEL BAY An airplane is not something you design, turn over to manufacturing, and then forget. The configuration is constantly changing. So you com- mit to a schedule, and then incorporate changes and improvements as they come. This task was especially critical because cost estimates assumed that assembly labor hours would decline predictably over time, following a preset learning curve. Managers therefore had to ensure that learning goals were met at the same time that they were accommodating unanticipated changes. SCHEDULING AND CHANGE CONTROL. Requests for changes came from internal and external sources. Some, such as the color of carpeting or seating arrangements, were negotiated by airline WEL YELLOD DOWS SO HAVEL ACAR SPAR BLAND ONTSPA SENTS WING BODY TALING EDGE FLAS SECTION SECTION 244) AT SPUTTER SUBSTRUCTURE SECTION BADEM DOOR- wwCEAR- SECTION #140 NDANDO PAS Guc LOWEN LORE CO who scor FARING PRESSURE OKC HOGE GEAR DOOMS SERVIC ET DOORS PU HORE THE CENPER SECTO EMERGENCY ESCAPE HAYDES WING BODY FANG AAL OO ACOR ONENTL -108 GEM LONG ROY GEAR 300 WAY ACELE COM COME PANDUCT THRUST REVE MORE SE SEWOR CHIS SOCCORS MAN LANDING BOO GOO OSTA ONS FOR UP INN NSTALLATION Kesh CALET RESEMBLY 387 customers; others, such as parts or wiring changes, were proposed by engineers. In total, the two sources generated 12,000 changes on the first 767. Managers tracked these changes carefully. Even before the plane's basic design was frozen, all major changes had to be filed using the same. formal procedure. This was done to ensure that specifications remained accurate. Once assembly began, a Production Change Board, chaired by the operations department, reviewed all engi- neering change requests and assessed their likely impact on schedule and cost. If the changes were approved, an implemention plan was then devel- oped. Three general approaches were used: incor- porating changes into the normal flow of production; installing old parts as originally planned and then retrofitting new parts off-line, outside the normal flow of production; and expediting changes by assigning additional workers, a process known as "blue streak." In all cases, a primary concern was main- taining schedule. Boeing faced substantial pen- alties if a plane was delivered even one day late, because airlines planned their schedules around promised delivery dates and expected a new plane to be flying immediately. According to Haas: For a long time, we have stressed the im- portance of schedule performance. The airplane will move (from one work station to the next] on the day that it is supposed to move. Management will get in a lot more trouble for not moving an airplane, assembly, or part on schedule than for a budget overrun. Over the years, budgets have gained significantly in importance, but not at the expense of schedules. To ensure that schedules were maintained, Boeing employed a management visibility system. Sched- ules were prominently posted, and marathon sta- tus meetings, which were attended by rep- resentatives of all affected departments, were held. weekly to review slippages and highlight potential problems. Every manager discussed what he or she was doing and what he or she was owed by others. The emphasis was on early notification, as Dennis Wilson observed: If I'm at a status meeting and I find that someone has missed a critical milestone, the first question I ask is. "Why didn't you tell me about the problem last week?", not, "Why did you miss. the milestone?" In June 1981, as assembly of the first 767 moved into its final stages, a First Flight Committee was established. The committee reported directly to Dean Thornton and met daily during the six weeks before the plane's first test flight. At that point, the test pilot had final say in setting priorities and selecting the tasks to be completed. LEARNING CURVES. Learning curves were also used to manage the assembly process. Based on historical experience, Boeing had developed learn ing curves for every major work center. Machining, assembly, and sheet metal fabrication had curves of their own, each with a different slope. However, curves were used in the same way at all centers. To begin, an optimum crew size was defined for the operation, based on available work space, engineering guidelines, and tooling to be em ployed. For example, the optimum crew size for forward body section assembly was eight people. A parametric estimate was then made of the number of labor hours needed to assemble that section of the very first 767. The total (in this case, 6,000 hours) was then divided by the number of labor hours available each day (in this case, 128 hours, equal to eight people working eight hours per shift, two shifts per day) to give the number of days to complete the very first assembly (47 days). At this point, a learning curve was invoked. The next assembly would be scheduled not for 47 days but for a lesser number, to reflect the his torical rate of learning on that operation. The same number of people would be employed, but they would work faster and more efficiently. (When precise calculations were impossible, Boeing var- ied staffing levels within minimum and maximum values, rather than sticking to a single, optimum crew size.) Learning curves were also applied to change management. Work centers were initially staffed to reflect a large number of changes. For example, of the eight people assigned to forward body section assembly, three might initially be respon- sible for incorporating changes. But because the number of changes fell sharply as more planes were produced the first 767 had 12,000 changes. while the seventieth 767 had only 500-fewer people would be needed for the activity as time passed, and staffing would be reduced over time. Such improvements did not come automat- ically. Three tools were used to ensure that targets were met: specific work station goals; stand-up meetings with first-line supervisors; and the man- agement visibility system discussed earlier. Hourly goals were set for every employee and displayed on bar charts by their work stations. prominently The game, as one manager put it, then became "worker versus bar chart." Stand-up meetings were held only if targets were not met. First-line supervisors had to stand up at these meetings and identify what was impeding their ability to meet learning curve goals. Managers were then responsible for solving the problems. Three-Crew to Two-Crew Conversion the late 1970s, airframe manufacturers, led by Boeing, proposed a switch from three- to two- person cockpits. Advanced technology, they ar- gued, had made a three-person crew unnecessary. The Air Line Pilots Association (ALPA) objected strongly to these arguments, claiming that safety levels were certain to fall if the number of crew members was reduced. To resolve the debate, a presidential task force was convened; both parties agreed to accept its findings. In July 1981, the task force concluced that two-person cockpits pre- sented no unusual safety problems, and that manufacturers could offer them on all planes. Airlines, including those that had already ordered 767s, soon expressed an interest in having their planes delivered with two-person cockpits. Boeing had anticipated such a response and, years earlier, had conducted preliminary studies to de- termine how best to convert the 767 from its original, three-person cockpit design to a two- person model (see Exhibit 5 for a comparison of the two cockpits). Further studies were immedi- ately begun; their goal was to identify the number of planes then in process that would require rework or modification to become two-crew models, and the likely impact of these changes on cost and schedule. Engineers concluded that the thirty- first 767 was still far enough from completion that it, and all subsequent planes, could be built with two-person cockpits without modification. Thirty planes, however, were in relatively advanced stages of production. Some were nearly ready to be rolled. out and flown; others had complete cockpits but. were not yet tested; others had bare cockpits without any electronics installed. But since all thirty were being built according to the plane's original, three-person cockpit design, all would require some modification. Customers were notified of the additional cost and delivery delay they could expect on these thirty planes. The impact was not large: a small percentage increase in costs and an average delay of one month from promised delivery dates. All but one airline chose to have their planes built with two-person cockpits. In August 1981 a special task force, reporting directly to Thornton, was formed to determine the best way of modifying these planes. It soon narrowed the choice to two alternatives: (1) build- ing the thirty airplanes as they had originally been designed, with three-person cockpits, and then converting them to two-person cockpits after they had left the production floor (but before delivery to customers), and (2) modifying the production plans for the thirty airplanes so that conversion would take place during production and no parts would be installed only to be removed. later (which meant leaving some cockpits tem- porarily unfinished while drawings and parts for two-person cockpits were being developed). COMPLETION OF PRODUCTION AND SUBSEQUENT MODIFICATION. In this approach, production would continue as planned, without delay. Neither learning curves nor schedules would be disrupted by attempts to modify airplanes during the as- sembly process. The modification program would be managed as a separate, tightly-controlled ac- tivity, apart from the normal flow of production, and special teams of "modification experts," skilled at parts removal, modification, and repair, would be assigned to it. Approximately one million ad- ditional labor hours were thought to be required if this method was used. The primary advantage of this approach was that flaps, ailerons, landing gear, hydraulics, and other airplane systems would be functionally tested during the final assembly process, as originally planned. Problems would be identified and cor- rected on the spot, rather than hidden or disguised by subsequent assembly activities. And because the airplane that rolled out of production would be fully tested and functional, any problems iden- EXHIBIT 5 Three-Crew and Two-Crew Cockpit Designs FLIGHT DECK ARRANGEMENTS 787.500 3 CREW MEMBERS FIRST OFFICER FLIGHT FLT KIT ENGINEER FIRST OFFICER CAPTAIN 1ST OBSERVER (BASIC) FLT KIT SUITCASES CLOSET/ SUITCASES 2ND OBS (OPTION) 2 CREW MEMBERS FLT KIT CAPTAIN 1ST OBSERVER (BASIC) FLT KIT CLOSET/ SUITCASES 2ND OBSERVER (OPTION) SUITCASES tified after installation of the two-person cockpit could be isolated, with some assurance, to the cockpit area. The risk of this approach was the potential "loss of configuration" (i.e., when the plane was actually built, the integrity of the overall design might be compromised). Parts required for three- person cockpits would be installed firmly in place, only to be removed and replaced later by modifi- cation experts. (Because these parts had been ordered months before and were already on-hand and paid for, this option did not impose greater scrap costs than the other option.) If the modifi- cation was not done carefully, many of the plane's operating systems might be disrupted. Boeing experts, however, believed that the management controls used for modification would prevent this. from occurring. To minimize the risk, additional functional testing would be required after modi- fication. Space was also a problem. There was not enough room within the factory to modify all thirty planes. Work would therefore have to be done outside, but even then space was limited. A special parking plan would have to be developed. and the planes being modified would have to be. parked extremely close together. The required arrangement would violate fire regulations, so special fire control plans and waivers would be necessary. Several managers had reservations about this approach, for they objected to its underlying philosophy. The end result would be an airplane that had been modified, after the fact, to accom- modate a two-person cockpit. As Standal put it: "It goes against our grain and better judgment to roll out an aircraft and then tear the guts out." MODIFICATION DURING PRODUCTION. In this approach, all modification of the thirty planes would be done during production, rather than after the fact. No parts would be installed only to be removed later. Instead, all panels, instruments, and switches that were associated with three- person cockpits would be identified and their installation halted. Meanwhile, production would continue on other sections of the plane. Once plans and parts were available for two-person cockpits, they would be incorporated within the flow of production. This was the traditional method of making engineering and design changes. It was used routinely for the thousands of configuration changes on every new airplane. The primary advantage of this approach was that all parts were installed only once. Because there would be no installation and subsequent removal, the configuration was more likely to remain secure. Moreover, because modification would occur during production, all activities would be controlled by normal manage- ment procedures, rather than by a separate pro- gram. The primary disadvantage of this approach was that the original production plan would be disrupted. Separate plans would have to be de- veloped for the first thirty airplanes, which re- quired modification, and all subsequent planes. Learning curves would be disrupted as well, be- cause a large number of additional workers would have to be added temporarily, at selected work stations, to complete the modification of the first thirty planes. If this method was used, modifica- tion was expected to require approximately two million additional labor hours. Because all cockpit work would be deferred. until engineering drawings and parts were avail- able for two-crew models, test procedures would also have to change. Traditionally, functional testing was done sequentially, with each system (flaps, ailerons, etc.) tested as it became opera- tional. That approach would be impossible her