Question: Two processes, EDM and wire EDM are being compared in an operation to create a 5.0 in diameter through hole in a 3.0 in

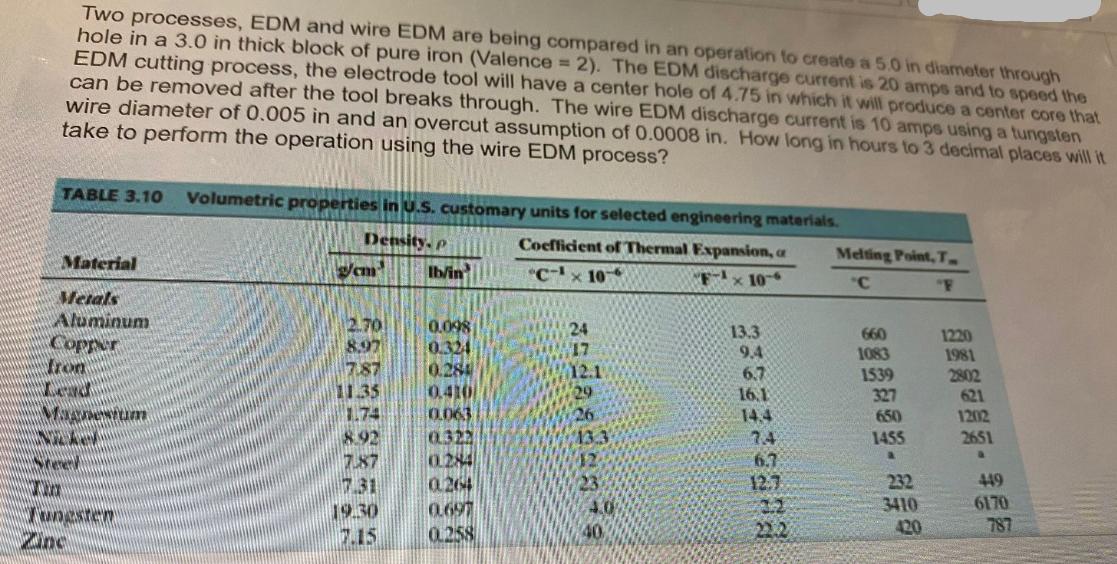

Two processes, EDM and wire EDM are being compared in an operation to create a 5.0 in diameter through hole in a 3.0 in thick block of pure iron (Valence = 2). The EDM discharge current is 20 amps and to speed the EDM cutting process, the electrode tool will have a center hole of 4.75 in which it will produce a center core that can be removed after the tool breaks through. The wire EDM discharge current is 10 amps using a tungsten wire diameter of 0.005 in and an overcut assumption of 0.0008 in. How long in hours to 3 decimal places will it take to perform the operation using the wire EDM process? TABLE 3.10 Volumetric properties in U.S. customary units for selected engineering materials. Density, p Coefficient of Thermal Expansion, a Cx 10 Fx10 Material Metals Aluminum Copper rober Vem 2.70 8,97 7.87 11.35 1.74 8.92 7.87 7.31 19.30 7.15 Ib/in 0.098 0.324 0.284 0.410 0.063 0.322 0.284 0.264 0.697 0.258 17 12.1 4.0 40 13.3 9.4 6.7 16.1 14.4 74 6.7 12.7 22.2 Melting Point, T. C "F 660 1083 1539 327 650 1455 a 232 3410 420 1220 1981 2802 621 1202 2651 a 449 6170 787

Step by Step Solution

3.21 Rating (154 Votes )

There are 3 Steps involved in it

Given data Dia of hole D 5 Dia of tungsten wire d0005 ... View full answer

Get step-by-step solutions from verified subject matter experts