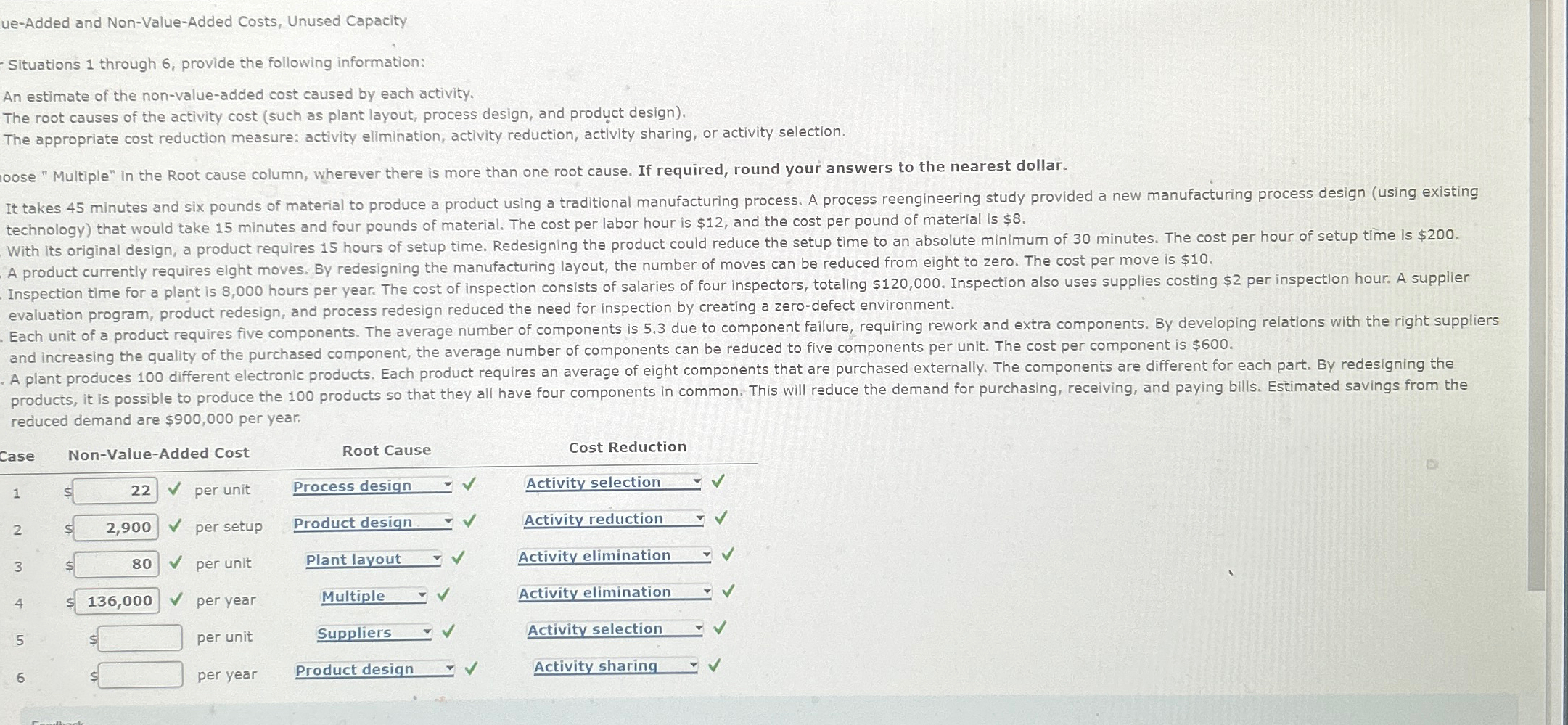

Question: ue - Added and Non - Value - Added Costs, Unused Capacity Situations 1 through 6 , provide the following information: An estimate of the

ueAdded and NonValueAdded Costs, Unused Capacity

Situations through provide the following information:

An estimate of the nonvalueadded cost caused by each activity.

The root causes of the activity cost such as plant layout, process design, and product design

The appropriate cost reduction measure: activity elimination, activity reduction, activity sharing, or activity selection.

oose "Multiple" in the Root cause column, wherever there is more than one root cause. If required, round your answers to the nearest dollar. technology that would take minutes and four pounds of material. The cost per labor hour is $ and the cost per pound of material is $

A product currently requires eight moves. By redesigning the manufacturing layout, the number of moves can be reduced from eight to zero. The cost per move is $ evaluation program, product redesign, and process redesign reduced the need for inspection by creating a zerodefect environment. and increasing the quality of the purchased component, the average number of components can be reduced to five components per unit. The cost per component is $ reduced demand are $ per year.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock