Question: unit operation(distillation column separating) 1. A distillation column separating benzene from toluene is shown below. Pressure is 1 bar. The feed containing 60 (mol %)

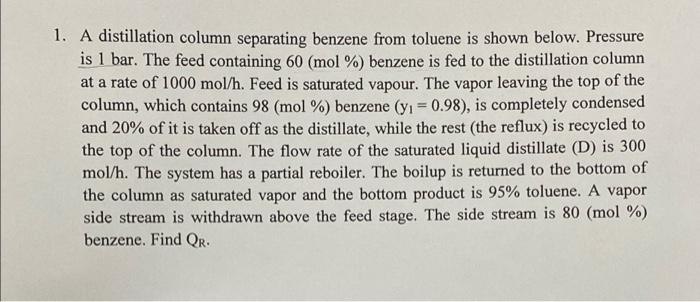

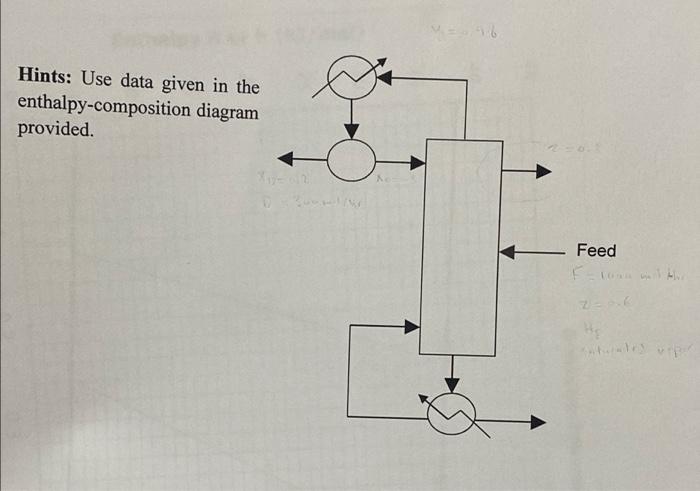

1. A distillation column separating benzene from toluene is shown below. Pressure is 1 bar. The feed containing 60 (mol %) benzene is fed to the distillation column at a rate of 1000 mol/h. Feed is saturated vapour. The vapor leaving the top of the column, which contains 98 (mol %) benzene (y1 = 0.98), is completely condensed and 20% of it is taken off as the distillate, while the rest (the reflux) is recycled to the top of the column. The flow rate of the saturated liquid distillate (D) is 300 mol/h. The system has a partial reboiler. The boilup is returned to the bottom of the column as saturated vapor and the bottom product is 95% toluene. A vapor side stream is withdrawn above the feed stage. The side stream is 80 (mol %) benzene. Find QR. 16 Hints: Use data given in the enthalpy-composition diagram provided. Feed 2 1. A distillation column separating benzene from toluene is shown below. Pressure is 1 bar. The feed containing 60 (mol %) benzene is fed to the distillation column at a rate of 1000 mol/h. Feed is saturated vapour. The vapor leaving the top of the column, which contains 98 (mol %) benzene (y1 = 0.98), is completely condensed and 20% of it is taken off as the distillate, while the rest (the reflux) is recycled to the top of the column. The flow rate of the saturated liquid distillate (D) is 300 mol/h. The system has a partial reboiler. The boilup is returned to the bottom of the column as saturated vapor and the bottom product is 95% toluene. A vapor side stream is withdrawn above the feed stage. The side stream is 80 (mol %) benzene. Find QR. 16 Hints: Use data given in the enthalpy-composition diagram provided. Feed 2

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts