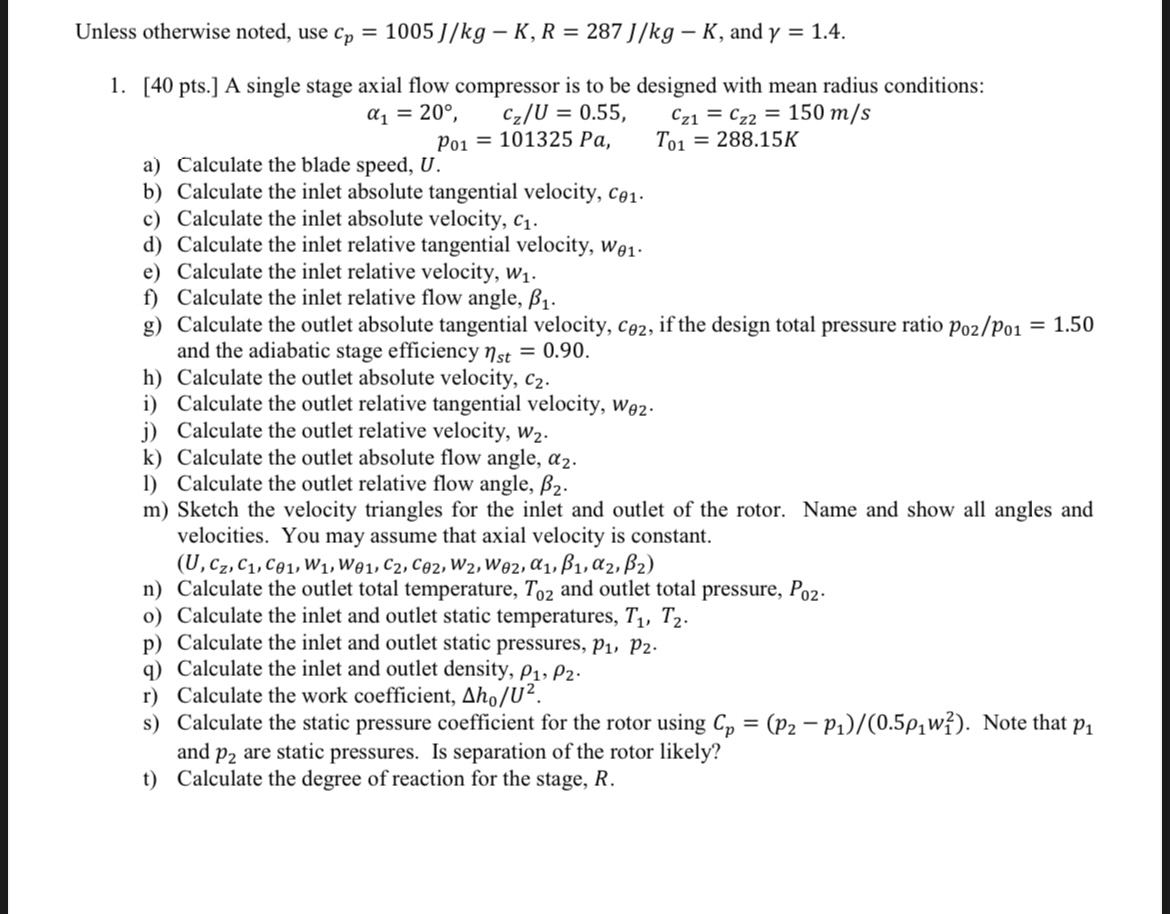

Question: Unless otherwise noted, use c p = 1 0 0 5 J k g - K , R = 2 8 7 J k g

Unless otherwise noted, use and

pts A single stage axial flow compressor is to be designed with mean radius conditions:

a Calculate the blade speed,

b Calculate the inlet absolute tangential velocity,

c Calculate the inlet absolute velocity,

d Calculate the inlet relative tangential velocity,

e Calculate the inlet relative velocity,

f Calculate the inlet relative flow angle,

g Calculate the outlet absolute tangential velocity, if the design total pressure ratio and the adiabatic stage efficiency

h Calculate the outlet absolute velocity,

i Calculate the outlet relative tangential velocity,

j Calculate the outlet relative velocity,

k Calculate the outlet absolute flow angle,

Calculate the outlet relative flow angle,

Sketch the velocity triangles for the inlet and outlet of the rotor. Name and show all angles and velocities. You may assume that axial velocity is constant.

n Calculate the outlet total temperature, and outlet total pressure,

o Calculate the inlet and outlet static temperatures,

p Calculate the inlet and outlet static pressures,

q Calculate the inlet and outlet density,

r Calculate the work coefficient,

s Calculate the static pressure coefficient for the rotor using Note that and are static pressures. Is separation of the rotor likely?

t Calculate the degree of reaction for the stage,

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock